Method for producing low-carbon olefins by using fixed bed

A low-carbon olefin and fixed-bed technology, which is applied in ethylene production, bulk chemical production, chemical instruments and methods, etc., can solve the problems of low selectivity of low-carbon olefins and low conversion rate of CO, and improve the selection of low-carbon olefins performance, increase the conversion rate of CO, and the effect of improving the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

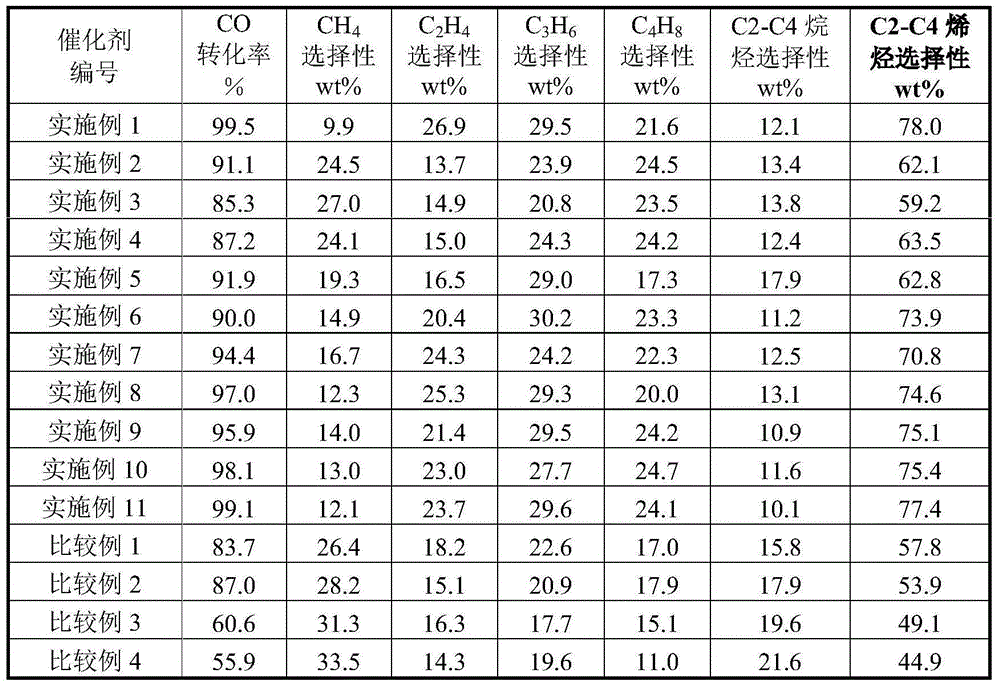

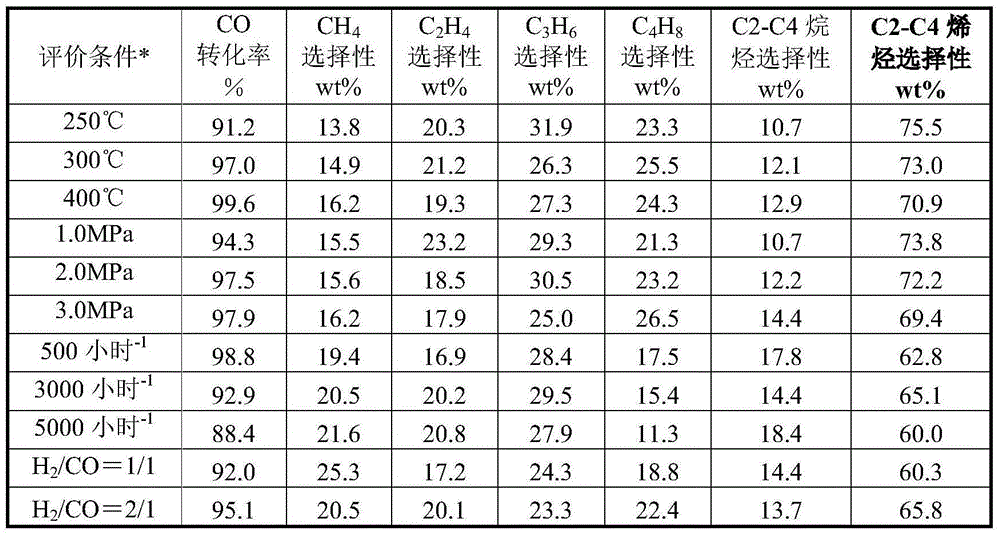

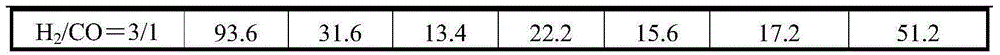

Examples

Embodiment 1

[0028] Weigh 60.0 grams of nano-titanium dioxide (TiO 2 ) powder and 40.0 grams of nano silicon dioxide (SiO 2 ) powders were mixed evenly, and mixed in a ball mill for 3 hours to make a mixture G for use; adding deionized water to the above-mentioned mixed material G for kneading and extrusion molding; after drying, the temperature of 800 ° C Lower roasting 3 hours, after cooling, crush and sieve into 20~40 orders to prepare composite carrier H; With 101.2 grams of ferric nitrate nonahydrate, 6.8 grams of rhodium nitrate, 45.6 grams of copper nitrate trihydrate, 32.2 grams of potassium nitrate, 4.0 grams of nitric acid hexahydrate Praseodymium is dissolved in 40.0 grams of deionized water to make a mixed solution I; under the condition of a vacuum of 80kPa, the above mixed solution I is impregnated in 45.0 grams of the prepared composite carrier H to obtain a catalyst precursor J; the impregnated catalyst Precursor J was dried at 110° C., and then calcined at 600° C. for 4 h...

Embodiment 2

[0030] Weigh 70.0 grams of nano-titanium dioxide (TiO 2 ) powder and 30.0 grams of nano silicon dioxide (SiO 2 ) powders were mixed evenly, and mixed in a ball mill for 3 hours to make mixture G for use; adding deionized water to the above-mentioned mixed mixture G, kneading and extruding; Down roasting 6 hours, after cooling, broken and sieved into 20~40 orders and prepared composite carrier H; 253.0 grams of iron nitrate nonahydrate, 2.3 grams of rhodium nitrate, 27.3 grams of copper nitrate trihydrate, 19.3 grams of potassium nitrate, 2.0 grams of nitric acid hexahydrate Praseodymium is dissolved in 40.0 grams of deionized water to make mixed solution I; under the condition of a vacuum of 80kPa, the above mixed solution I is impregnated in 30.0 grams of prepared composite carrier H to obtain catalyst precursor J; the impregnated catalyst Precursor J is dried at 110° C., and then calcined at 600° C. for 4 hours to obtain the desired fixed-bed iron-based catalyst for produci...

Embodiment 3

[0032] Weigh 20.0 grams of nano-titanium dioxide (TiO 2 ) powder and 80.0 grams of nano silicon dioxide (SiO 2 ) powders were mixed evenly, and mixed in a ball mill for 3 hours to make a mixture G for use; adding deionized water to the above-mentioned mixed material G for kneading and extrusion molding; Lower roasting 1 hour, after cooling, crush and sieve into 20~40 orders to prepare composite carrier H; 50.6 grams of iron nitrate nonahydrate, 2.3 grams of rhodium nitrate, 27.3 grams of copper nitrate trihydrate, 19.3 grams of potassium nitrate, 2.0 grams of nitric acid hexahydrate Praseodymium is dissolved in 50.0 grams of deionized water to make a mixed solution I; under the condition of a vacuum of 80kPa, the above mixed solution I is impregnated in 70.0 grams of the prepared composite carrier H to obtain a catalyst precursor J; the impregnated catalyst Precursor J is dried at 110° C., and then calcined at 600° C. for 4 hours to obtain the desired fixed-bed iron-based cat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com