Maca solid drink and preparing method thereof

A technology of solid beverages and maca, which is applied in pharmaceutical formulas, plant raw materials, essential oils/spices, etc. It can solve problems such as inability to extract, easy residues in products, and unsafe products, so as to ensure product quality and effectiveness , the effect of ensuring product safety and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

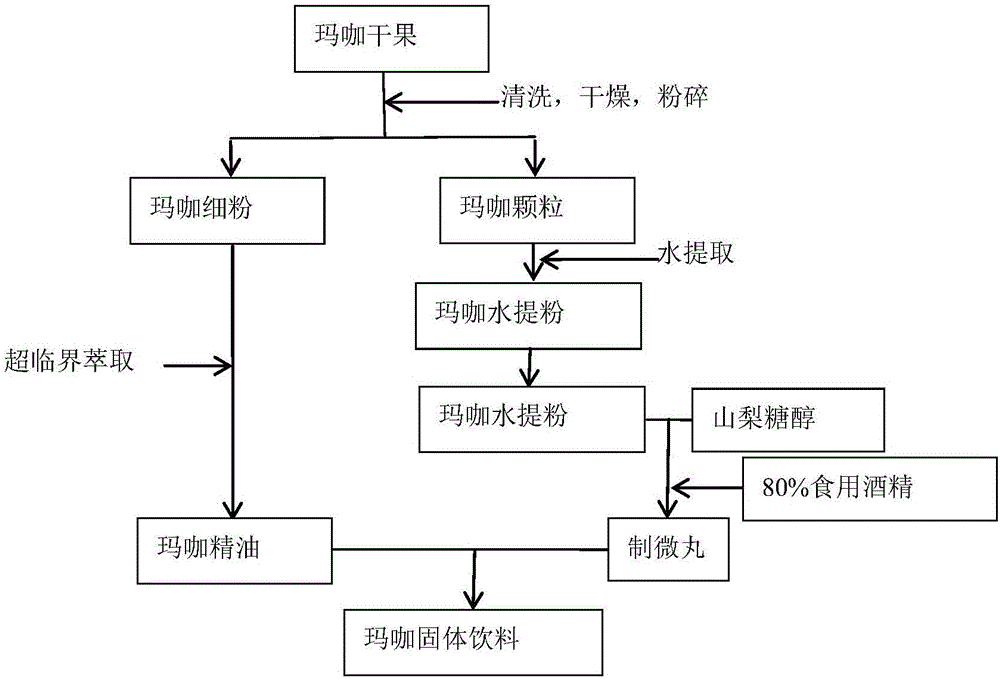

[0046] Such as figure 1 The schematic diagram of the preparation process shown, the specific preparation method is:

[0047] a. Preparation of maca water extraction powder: take dried maca fruit, remove impurities, wash and dry, pulverize into 10-20 mesh particles, add 8-20 times of water to boil and extract for 2-3 hours to form a concentrated solution, spray dry to obtain Maca water extract powder with water content less than 2%;

[0048] b. Preparation of maca essential oil: take dried maca fruit, remove impurities, wash and dry, pulverize into 40-60 mesh fine powder, control the water content of maca powder below 5%, extract with supercritical carbon dioxide, and extract with an extraction pressure of 30-35MPa, The extraction temperature is 40-50°C, the extraction is 2-3 hours, and the extract is separated in a separation kettle with a pressure of 4-8MPa and a temperature of 30-64°C to obtain maca essential oil;

[0049] c. Preparation of solid beverage: mix 180-200-mesh...

Embodiment 1

[0052] Take 10 kg of dried Maca fruit, remove impurities, wash, dry, crush into 10-20 mesh particles, add 200 kg of water, extract by boiling for 2 hours, concentrate to 10 kg of concentrated solution, spray dry at 165°C to obtain Maca Water extraction powder.

[0053] Take 50 kg of maca dried fruit, remove impurities, wash, dry, and pulverize into 40-60 mesh fine powder with a water content of 4%. In a supercritical carbon dioxide extraction equipment, the extraction pressure is 32MPa and the extraction temperature is 45°C. After 2 hours, release it in a separation kettle with a pressure of 4MPa and a temperature of 40°C to obtain maca essential oil;

[0054] Maca water extraction powder and sorbitol superfine powder are mixed evenly to obtain a mixed powder, and 80% edible alcohol is used as a binder to make the mixed powder into 20-50 mesh pellets, and after low-temperature drying, the maca The essential oils are all added in the pellets to obtain 4.5kg of Maca solid bever...

Embodiment 2

[0056] Take 100 kg of Maca Maca dried fruit, remove impurities, wash, dry, crush into 10-mesh particles, add 1000 kg of water, extract by boiling for 2 hours, concentrate to 1 / 4 volume, spray dry at 165°C until the water content is less than 2% , that is, maca water extraction powder.

[0057]Take 2000 kg of Maca dried fruit, remove impurities, wash, dry, and pulverize into 40-60 mesh fine powder with a water content of 3%. In a supercritical carbon dioxide extraction equipment, the extraction pressure is 30MPa and the extraction temperature is 50°C. After 2 hours, release the extract in a separation kettle with a pressure of 4 MPa and a temperature of 37° C. to obtain maca essential oil.

[0058] Maca water extraction powder and sorbitol superfine powder are mixed evenly to obtain a mixed powder, and 85% edible alcohol is used as a binder to make the mixed powder into 20-50 mesh pellets, and after low-temperature drying, the maca The essential oils are all added in the pelle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com