A thermosensitive vascular embolization material capable of long-term autoradiography and its preparation method

A vascular embolism and temperature-sensitive technology, which is applied in the field of long-term self-imaging temperature-sensitive vascular embolization materials and its preparation, can solve the problems of incomplete embedding, affecting the imaging effect, increasing the patient's physical injury and treatment costs, and achieving good embolization performance, good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The invention provides a method for preparing a temperature-sensitive vascular embolism material capable of long-term autoradiography, comprising the following steps:

[0043] (1) After acrylamide compound, tert-butyl acrylate or its derivatives are mixed with organic solvent, liquid nitrogen freezing treatment is carried out;

[0044] (2) Under a protective atmosphere, the liquid nitrogen frozen material obtained in the step (1) is mixed with bis[2-(2'-bromoisobutyryloxy)ethyl]disulfide, ligand and copper system Catalyst mixing to carry out polymerization reaction;

[0045] (3) mixing the polymerization reaction product obtained in the step (2) with trifluoroacetic acid and an organic solvent, and performing a hydrolysis reaction to obtain a polyacrylamide polymer;

[0046] (4) The polyacrylamide polymer obtained in the step (3) is mixed with the gold nano-sol, and reacted under stirring conditions to obtain the gold nano-gel;

[0047] (5) mixing the gold nanogel obt...

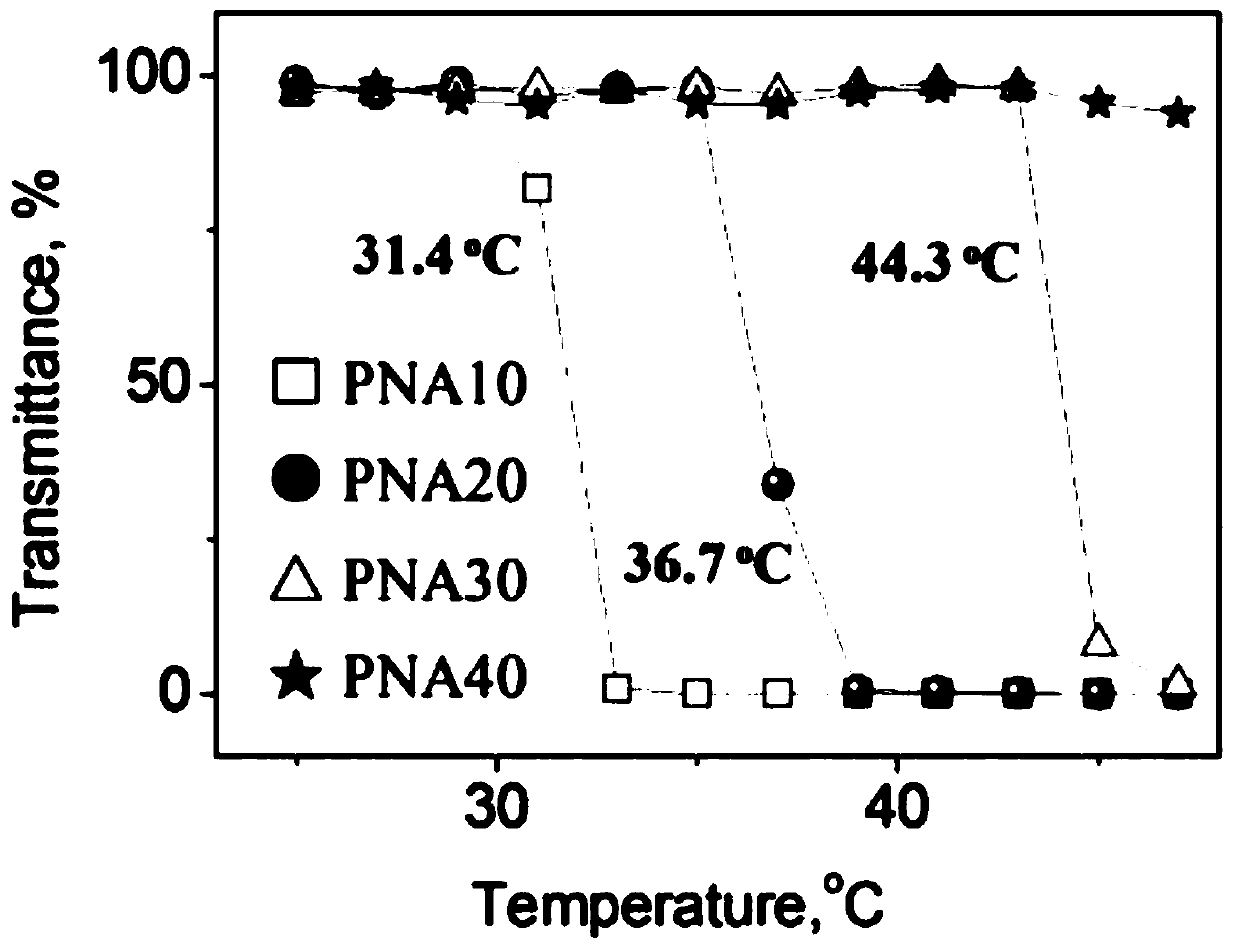

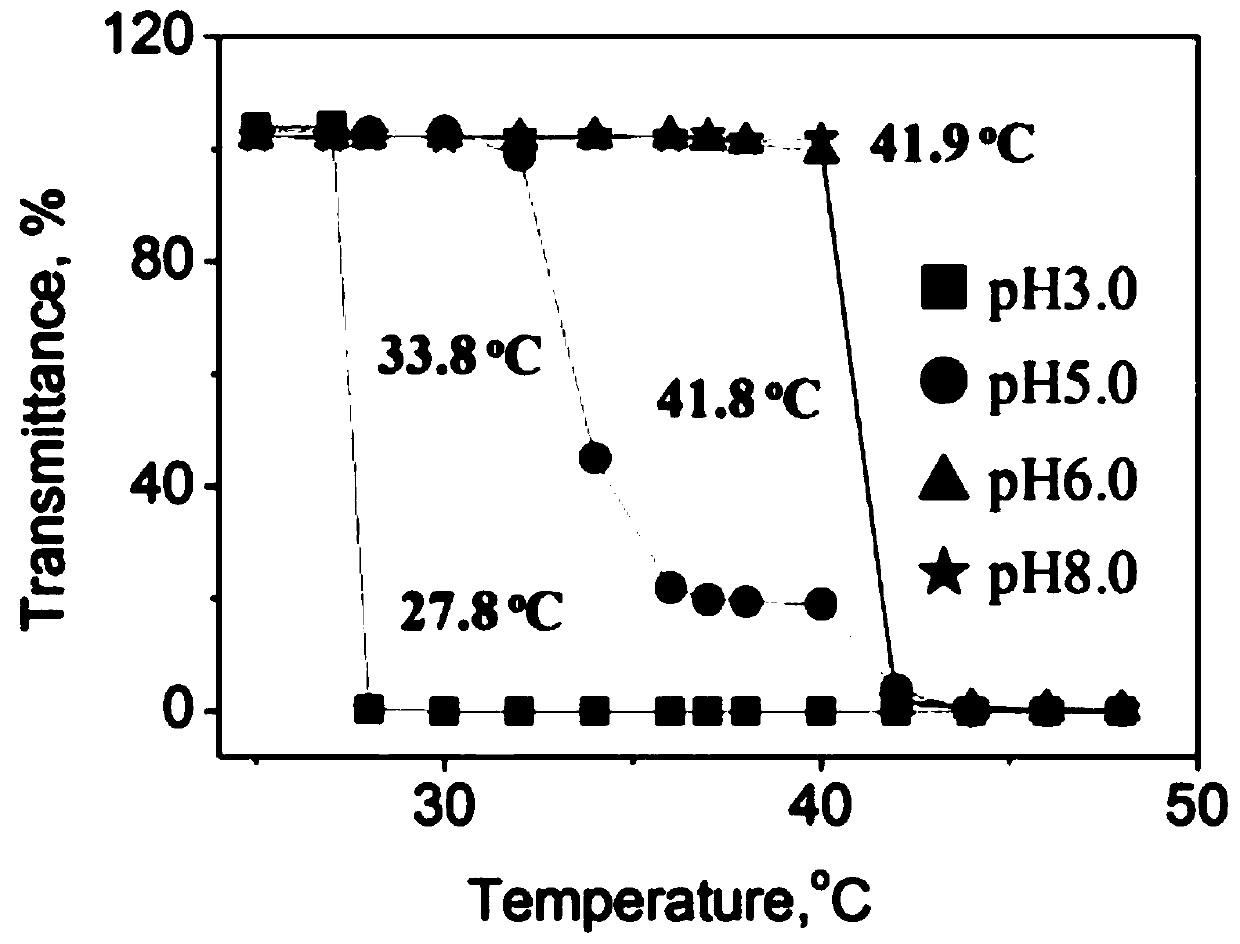

Embodiment 1

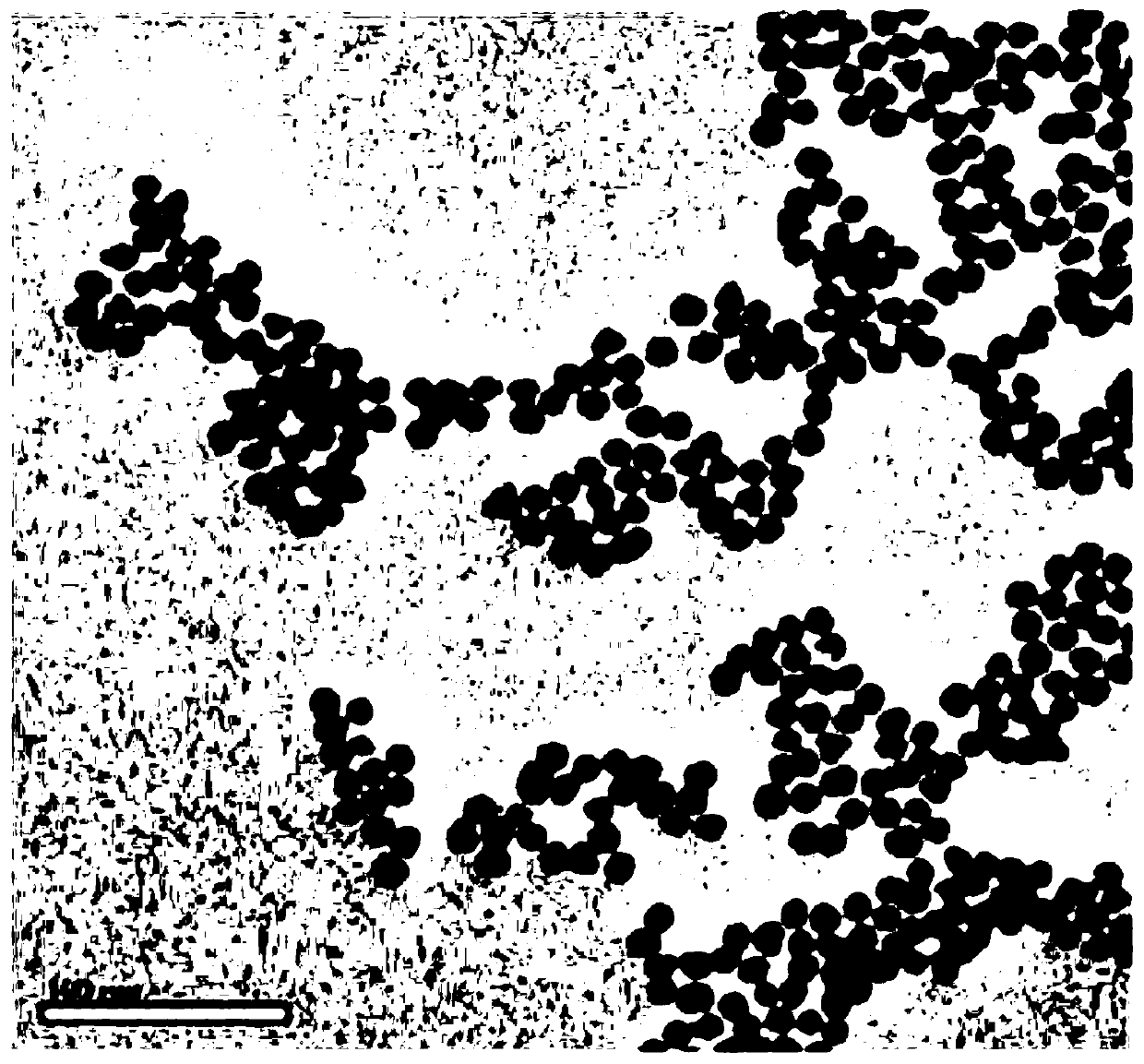

[0090] 10mL of gold chlorate solution with a molar concentration of 100mmol / L was mixed with 92mL of ultrapure water, heated in an oil bath at 120°C under stirring at 800rpm, and 8mL of gold chlorate solution with a molar concentration of 49mmol / L (mass Concentration or molar concentration) sodium citrate solution, continue stirring reaction 15min, obtain gold nano sol.

[0091] The gold nano sol prepared in Example 1 was diluted with ultrapure water until the mass percentage concentration of the gold nanoparticles in the gold nano sol was 0.01%, as the sample to be tested; Nano-ZS90 laser particle size analyzer (Malvern, UK) was used company) to measure the average particle size of gold nanoparticles in the sample to be tested, the light source is a helium-neon laser (λ=633nm), and the detection angle is 90°. The experimental results show that the particle size of gold nanoparticles in the sample to be tested is 13±1 nm at 25° C.

Embodiment 2

[0093] Mix 10mL of gold chlorate solution with a molar concentration of 100mmol / L and 92mL of ultrapure water, stir at 700rpm, heat in an oil bath at 130°C, and add 8mL of gold chlorate solution with a molar concentration of 49mmol / L (mass concentration or molar concentration) sodium citrate solution, continue to stir and react for 30min to obtain gold nano sol.

[0094] The gold nano sol prepared in Example 1 was diluted with ultrapure water until the mass percent concentration of the gold nanoparticles in the gold nano sol was 0.1%, as the sample to be tested; Nano-ZS90 laser particle size analyzer (Malvern, UK) was used company) to measure the average particle size of gold nanoparticles in the sample to be tested, the light source is a helium-neon laser (λ=633nm), and the detection angle is 90°. The experimental results show that the particle size of gold nanoparticles in the sample to be tested is 15nm at 25°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com