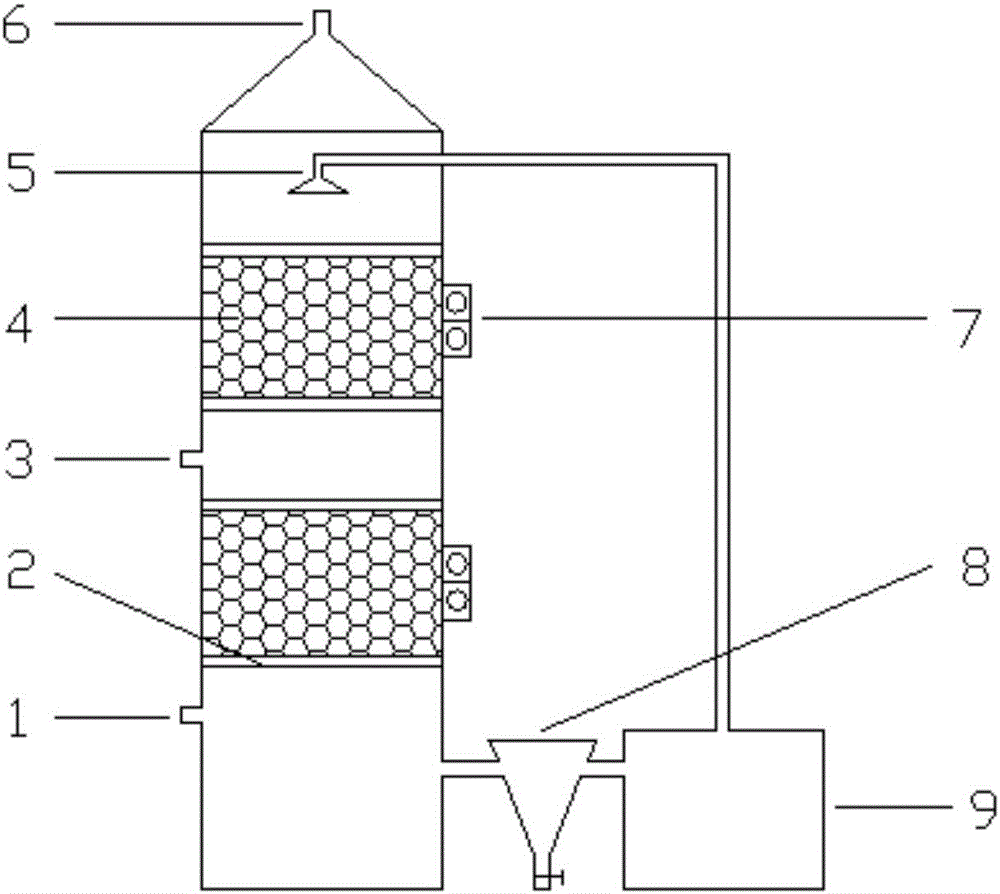

Bio-trickling filter for producing sulphur by removing hydrogen sulfide and method thereof

A biological trickling filter tower, hydrogen sulfide technology, applied in the field of desulfurization, can solve the problems of waste, less investment, sulfur blockage, etc., and achieve the effects of uniform load, low operating cost, and large porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] a. Mix 0.5 mol of ferric chloride solution and SiC according to the solid-liquid volume ratio of 1:3 to form a solid-liquid mixture.

[0060] b. Place the solid-liquid mixture in an ultrasonic generator, and ultrasonically treat it at 25Hz and 400W for 2~3h; filter the solution and dry it at 105℃ for 6h;

[0061] c. Calcining the dried sample at 400°C for 3 hours, cooling to room temperature after calcination, and then performing ultrasonic vibration for 60 minutes for 50 minutes to obtain the final product after vibration, namely the modified loaded biological filler, as the first filler layer and the second filler layer The filler; the doping amount of the modified loaded biological filler is n(Fe)=0.5-0.9%, and the airflow distribution plate 2 of the first filler layer in the biological trickling filter tower is placed 25cm away from the bottom of the tower.

[0062] d. The modified loaded biological filler of step c is statically preliminarily coated with the high-efficien...

Embodiment 2

[0065] a. Put the honeycomb SiC in the container, and then add 0.6 mol FeCl 3 Solution to form SiC and FeCl 3 According to the solid-liquid volume ratio 1:3.5 solid-liquid mixture.

[0066] b. Put the solid-liquid mixture in an ultrasonic generator, and use 20-25kHz ultrasonic treatment for 3 hours, filter the processed sample, and dry it at 105°C for 3 hours.

[0067] c. The dried sample obtained in step b is calcined, the temperature is controlled at 400-600°C, heated for 3 hours, and then cooled to room temperature with the furnace to obtain Fe / SiC filler, and then subjected to ultrasonic vibration for 60 minutes to obtain a modified loaded biological filler as The filler of the first packing layer and the second packing layer; the doping amount of the modified loaded biological filler is n(Fe)=0.5~0.9%, the airflow distribution plate 2 of the first packing layer in the biological trickling filter tower is at the distance from the tower Place at the bottom 25cm.

[0068] d. The m...

Embodiment 3

[0071] a. Put the honeycomb SiC in the container, and then add 1 mole of FeCl 3 Solution to form SiC and FeCl 3 According to the solid-liquid volume ratio 1:3 solid-liquid mixture.

[0072] b. Put the solid-liquid mixture in an ultrasonic generator, use 20-25kHz ultrasonic treatment for 2.5 hours, filter the processed sample, and dry it at 110°C for 4 hours.

[0073] c. Calcining the dried sample obtained in step b, controlling the temperature at 500°C, heating for 3 hours, and then cooling to room temperature with the furnace to obtain Fe / SiC filler, and then performing ultrasonic vibration for 60 minutes to obtain the modified loaded biological filler as the first The filler layer and the second filler layer; the doping amount of the modified loaded biological filler is n(Fe)=0.5~0.9%, the air distribution plate 2 of the first filler layer in the biological trickling filter tower is 25cm away from the bottom of the tower Placed at.

[0074] d. The modified loaded biological filler...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com