Treatment device and method for waste acid containing heavy metals, fluorides and chlorides

A technology for waste acid treatment and heavy metal, applied in chemical instruments and methods, hydrogen fluoride, sulfur compounds, etc., can solve the problems of arsenic concentration not meeting the emission standard, inability to remove fluoride, chloride, and difficult to handle the slurry after neutralization, Achieve the effect of safe oxidation reaction and tail gas treatment, reducing equipment space layout and low treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

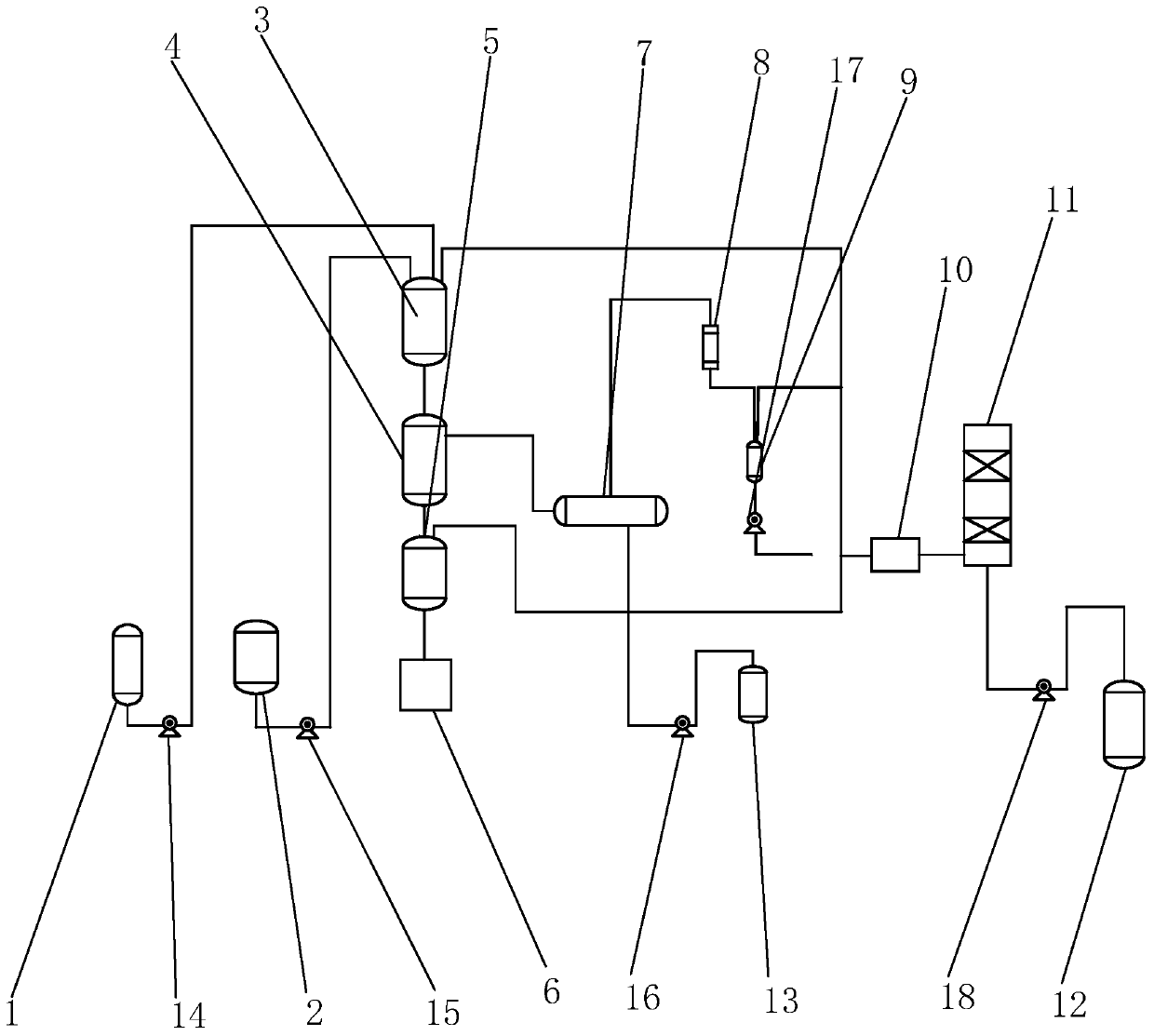

[0031] Embodiment: a kind of waste acid treatment device and method containing heavy metal, fluoride and chloride, such as figure 1 , a waste acid treatment device and method containing heavy metals, fluorides, and chlorides, including an oxidant preparation system, a heavy metal reaction system, a membrane filter impurity system, a salt evaporation crystallization system, an acid evaporation rectification separation system, and an exhaust gas absorption system. The flow process mainly includes the following steps: 1), the dilute sulfuric acid containing heavy metals enters the oxidation reactor 3 through the waste acid feed pump 14 and the prepared oxidant through the oxidant feed pump 15; 2), the oxidation reactor 3 adopts stirring Mixed reaction to increase the reaction rate of oxidants and heavy metals; 3), a small amount of organic waste gas reacted is pumped to the tail gas absorption tower 11 by fan 10 for washing and absorption; 4), sulfate impurities from the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com