Spherical porous adsorbent based on carbon nanotubes as well as preparation method and application of spherical porous adsorbent

A Porous Adsorbent, Carbon Nanotube Technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

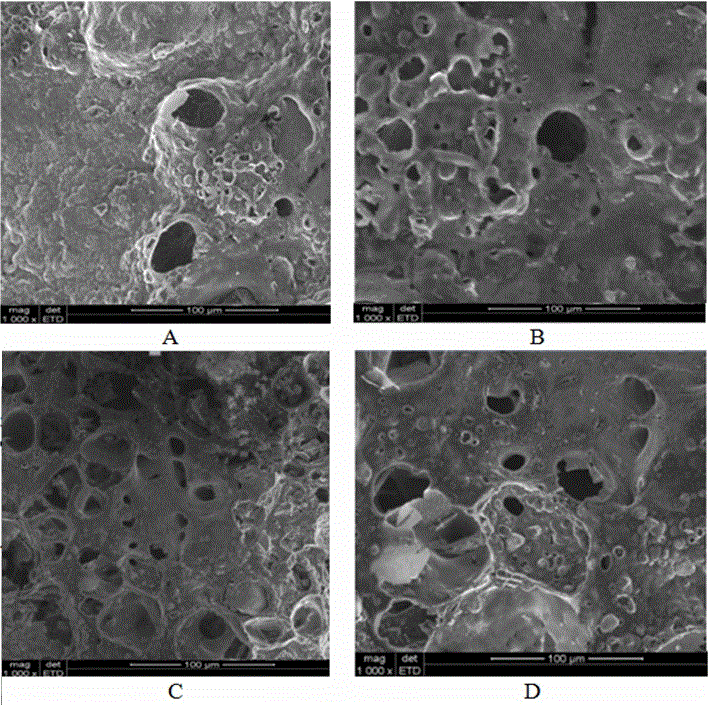

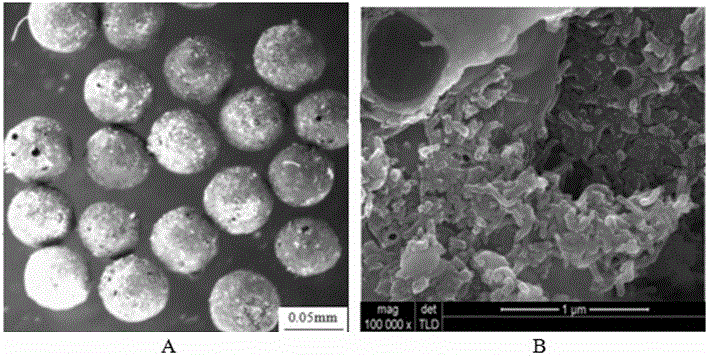

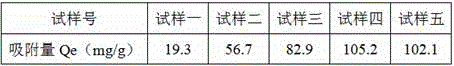

Embodiment 1

[0021] Put 3.24 parts of β-cyclodextrin, 3.24 parts of distilled water and 0.004 parts of sodium borohydride in a round bottom flask, heat in a water bath at 30°C and 350~550rpm and stir evenly, then add 4.53 parts of epichlorohydrin, 5.0 part of NaOH (40wt%) solution, continue to stir for 20 minutes, then add 0.36 part of multi-walled carbon nanotubes, 0.2 part of cetyltrimethylammonium bromide, stir well, then add 52.7 parts of liquid paraffin, and stir mechanically at constant temperature for 6 hours; After the end, the reaction product was washed with petroleum ether, ethanol, and distilled water several times until the liquid paraffin was washed, and then the product was placed in a vacuum drying oven at 60°C to heat and dry to obtain a carbon nanotube / β-cyclodextrin composite material , and then placed in a nitrogen atmosphere furnace for calcination at 500°C for 5 hours to obtain a spherical porous adsorbent with a carbon nanotube content of 82%.

Embodiment 2

[0023] Put 2.52 parts of β-cyclodextrin, 2.52 parts of distilled water and 0.004 parts of sodium borohydride in a round bottom flask, heat in a water bath at 30°C and 350~550rpm and stir evenly, then add 3.52 parts of epichlorohydrin, 3.5 1 part of NaOH (40wt%) solution, continue to stir for 20 minutes, then add 1.08 parts of multi-walled carbon nanotubes, 0.2 parts of cetyltrimethylammonium bromide, stir well, then add 52.7 parts of liquid paraffin, and stir mechanically at constant temperature for 6 hours; After the end, the reaction product was washed with petroleum ether, ethanol, and distilled water several times until the liquid paraffin was washed, and then the product was placed in a vacuum drying oven at 60°C to heat and dry to obtain a carbon nanotube / β-cyclodextrin composite material , and then placed in a nitrogen atmosphere furnace for calcination at 500°C for 5 hours to obtain a spherical porous adsorbent with a carbon nanotube content of 86%.

Embodiment 3

[0025] Put 1.8 parts of β-cyclodextrin, 1.8 parts of distilled water and 0.004 parts of sodium borohydride in a round bottom flask, heat in a water bath at 30°C and 350~550rpm and stir evenly, then add 2.5 parts of epichlorohydrin, 2.8 1 part of NaOH (40wt%) solution, continue to stir for 20 minutes, then add 1.8 parts of multi-walled carbon nanotubes, 0.2 parts of cetyltrimethylammonium bromide, stir well, then add 52.7 parts of liquid paraffin, and stir mechanically at constant temperature for 6 hours; After the end, the reaction product was washed with petroleum ether, ethanol, and distilled water for several times until the liquid paraffin was washed, and then the product was placed in a vacuum drying oven at 60°C to heat and dry to obtain a carbon nanotube / β-cyclodextrin composite material , and then placed in a nitrogen atmosphere furnace for calcination at 500°C for 5 hours to obtain a spherical porous adsorbent with a carbon nanotube content of 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com