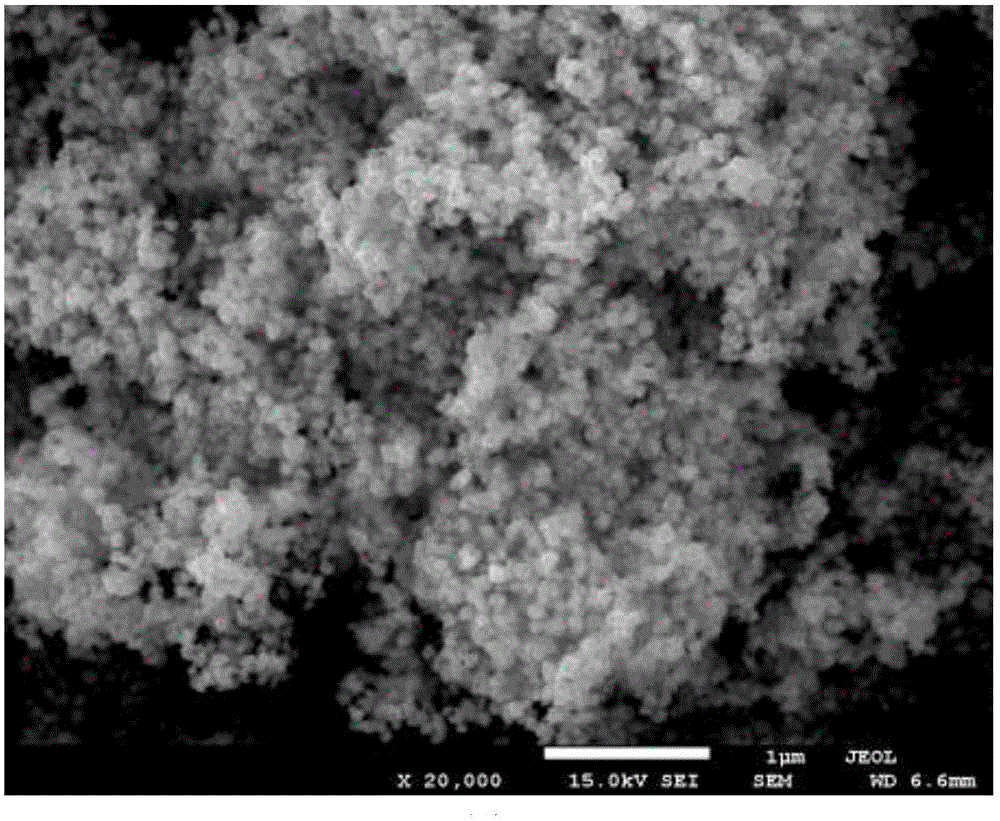

Nanoscale platinum-rhodium alloy powder and preparing method thereof

A platinum-rhodium alloy, nano-scale technology, applied in the field of nano-scale platinum-rhodium alloy powder and its preparation, can solve the problems of high slurry fineness, easy agglomeration of alloy powder, open circuit of electrode wires, etc., achieve good printing performance and avoid agglomeration The effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of platinum rhodium alloy powder (5g), preparation technology is as follows:

[0028] (1) Preparation of platinum-rhodium mixed solution: use deionized water to dissolve chloroplatinic acid and hydrated rhodium trichloride solid, Pt 4+ with Rh 3+ The mass ratio of is 2:3, obtains platinum-rhodium mixed solution 1L, in mixed solution Pt 4+ with Rh 3+ The concentration sum is 5g / L;

[0029] (2) Adjustment of the pH of the platinum-rhodium mixed solution: the pH value of the mixed solution in (1) is prepared using ammonia water to be 3;

[0030] (3) Preparation of dispersant: the mass fraction of glycerin dispersant prepared by deionization is 4%;

[0031] (4) Reduction: get the mixed solution in step (2), put into five 250ml polytetrafluoroethylene respectively in the stainless steel reaction kettle of liner, each reaction kettle adds the hydrazine hydrate reducing agent of 2ml, each reaction Add 1ml of the dispersant in step (3) to the kettle, stir evenly, an...

Embodiment 2

[0038] A kind of platinum rhodium alloy powder (10g), preparation technology is as follows:

[0039] (1) Preparation of platinum-rhodium mixed solution: use deionized water to dissolve chloroplatinic acid and hydrated rhodium trichloride solid, Pt 4+ with Rh 3+ The mass ratio of is 1:1, obtains platinum-rhodium mixed solution 1L, in mixed solution Pt 4+ with Rh 3+ The concentration sum is 10g / L;

[0040] (2) Adjustment of the pH of the platinum-rhodium mixed solution: use sodium fluoride to prepare the pH value of the mixed solution in (1) to be 4;

[0041] (3) Preparation of dispersant: the mass fraction of polyvinyl alcohol dispersant prepared by deionization is 10%;

[0042] (4) Reduction: Take the mixed solution in step (2), put it into five 250ml polytetrafluoroethylene-lined stainless steel reaction kettles, add 5ml of formaldehyde reducing agent to each reaction kettle, and add 5ml of formaldehyde reducing agent to each reaction kettle. In step (3), add 1ml of disp...

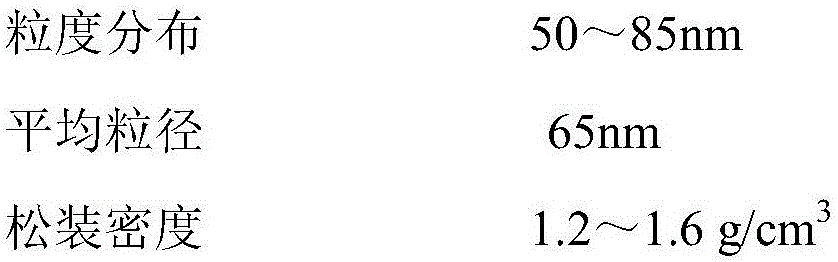

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size distribution | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com