Extracting method for medium and low temperature hemicellulose

A hemicellulose, low-temperature technology, applied in the chemical industry, can solve the problems of low yield, long extraction time, difficult separation and purification, etc., and achieve the effects of simple operation, improved yield and purity, and improved separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

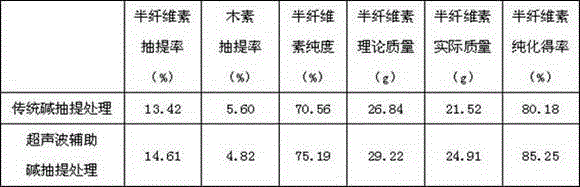

Embodiment 1

[0017] The chemical composition of wheat straw is as follows: the total cellulose content is 71.23%, and the hemicellulose (pentose) content in the total cellulose accounts for 23.29% of the straw chemical composition; the total lignin content is 22.96%;

[0018] The present invention in concrete implementation, comprises the following steps:

[0019] (1) Raw material processing: cut the wheat straw into 1cm long, wash it with water, remove dust and impurities, and air dry;

[0020] (2) Degreasing: Degreasing the air-dried wheat straw with benzene alcohol solution for 6 hours, the reaction temperature is 50°C, the solid-to-liquid ratio of wheat straw and benzene alcohol solution is 1:10, the lipids in the raw materials are removed, and air-dried to obtain degreased wheat straw;

[0021] The benzyl alcohol solution is made by mixing toluene and ethanol with a volume ratio of 2:1;

[0022] (3) Ultrasonic-assisted alkali extraction: add 200g of defatted wheat straw to lye, when...

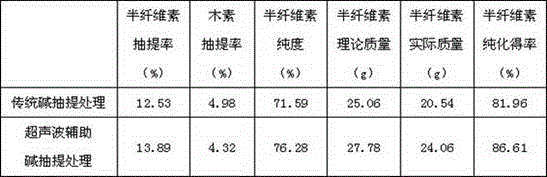

Embodiment 2

[0030] The chemical components of corn stalks are as follows: hemicellulose content 69.73%, of which the hemicellulose (polypentose) content in the total cellulose accounts for 19.65% of the chemical components of the straw; the total lignin content is 17.89%; Contains hemicellulose.

[0031] In specific implementation, the present invention may also include the following steps:

[0032] (1) Raw material processing: remove the pith from the corn stalks, cut them into 2cm×2cm pieces, wash them with water, remove dust and impurities, and air dry;

[0033] (2) Degreasing: Degreasing the air-dried corn stalks with benzene alcohol solution for 6 hours, the reaction temperature is 50°C, the solid-to-liquid ratio of corn stalks and benzene alcohol solution is 1:10, the lipids in the raw materials are removed, and air-dried to obtain defatted cornstalks;

[0034] The benzyl alcohol solution is made by mixing toluene and ethanol with a volume ratio of 2:1;

[0035] (3) Ultrasonic-as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com