Elastic sealant and preparation method

A technology of elastic sealing and sealant, which is applied in the field of sealant, can solve the problems of insufficient elastic sealant, etc., and achieve the effects of excellent anti-ultraviolet aging performance, environmental friendliness, and increased hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

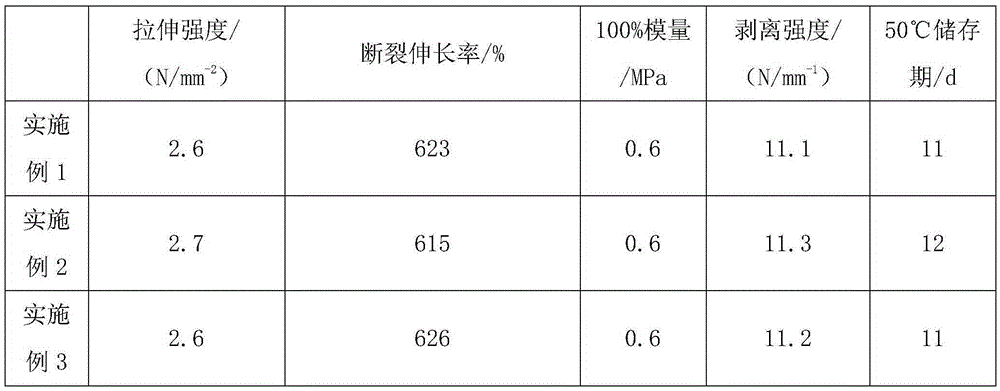

Examples

Embodiment 1

[0033] Prepare as follows:

[0034] S1: Weigh each raw material according to the ratio of parts by weight;

[0035] S2: Use polyether diol and polyether triol as soft segment, toluene diisocyanate, 3,3'-dichloro-4,4'-diaminodiphenylmethane as hard segment, stannous octoate as catalyst Synthesis of polyurethane prepolymers, wherein polyether diols and polyether triols are dehydrated before the synthesis reaction;

[0036]S3: To the polyurethane prepolymer obtained in S2, add dioctyl phthalate, tetra-oil, rutile titanium dioxide, light calcium carbonate, talcum powder, sericite, diatomaceous earth, 2,2- Dimorpholino diethyl ether, bis(2,6-dimethylmorpholino) ether, dibutyltin diacetylacetonate, 2,5(6)-diaminomethylbicyclo(2,2,1) Heptane, benzaldehyde, octanoic acid, 1,5,4-amino-3,3 dimethylbutyltrimethoxysilane, UV stabilizer, antioxidant, and in the process of adding each raw material, keep stirring to mix evenly ;

[0037] S4: Vacuumize the mixture obtained in S3 to remove...

Embodiment 2

[0039] Prepare as follows:

[0040] S1: Weigh each raw material according to the ratio of parts by weight;

[0041] S2: Use polyether diol and polyether triol as soft segment, toluene diisocyanate, 3,3'-dichloro-4,4'-diaminodiphenylmethane as hard segment, stannous octoate as catalyst Synthesis of polyurethane prepolymers, wherein polyether diols and polyether triols are dehydrated before the synthesis reaction;

[0042] S3: To the polyurethane prepolymer obtained in S2, add dioctyl phthalate, tetra-oil, rutile titanium dioxide, light calcium carbonate, talcum powder, sericite, diatomaceous earth, 2,2- Dimorpholino diethyl ether, bis(2,6-dimethylmorpholino) ether, dibutyltin diacetylacetonate, 2,5(6)-diaminomethylbicyclo(2,2,1) Heptane, benzaldehyde, octanoic acid, 1,5,4-amino-3,3 dimethylbutyltrimethoxysilane, UV stabilizer, antioxidant, and in the process of adding each raw material, keep stirring to mix evenly ;

[0043] S4: Vacuumize the mixture obtained in S3 to remov...

Embodiment 3

[0045] Prepare as follows:

[0046] S1: Weigh each raw material according to the ratio of parts by weight;

[0047] S2: Use polyether diol and polyether triol as soft segment, toluene diisocyanate, 3,3'-dichloro-4,4'-diaminodiphenylmethane as hard segment, stannous octoate as catalyst Synthesis of polyurethane prepolymers, wherein polyether diols and polyether triols are dehydrated before the synthesis reaction;

[0048] S3: To the polyurethane prepolymer obtained in S2, add dioctyl phthalate, tetra-oil, rutile titanium dioxide, light calcium carbonate, talcum powder, sericite, diatomaceous earth, 2,2- Dimorpholino diethyl ether, bis(2,6-dimethylmorpholino) ether, dibutyltin diacetylacetonate, 2,5(6)-diaminomethylbicyclo(2,2,1) Heptane, benzaldehyde, octanoic acid, 1,5,4-amino-3,3 dimethylbutyltrimethoxysilane, UV stabilizer, antioxidant, and in the process of adding each raw material, keep stirring to mix evenly ;

[0049] S4: Vacuumize the mixture obtained in S3 to remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com