Method capable of determining nine haloacetic acids in air or waste gas at the same time in one time

A haloacetic acid, one-time technology, applied in the field of environmental testing, can solve problems such as inapplicable exhaust gas measurement, achieve the effects of improving test accuracy, avoiding corrosion, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Use a single adsorption tube (200mg at the front and 100mg at the end) filled with silica gel to absorb and collect haloacetic acid compounds in the ambient air, open both ends of the adsorption tube at the sampling site, connect the adsorption tube to the atmospheric sampler, and set the gas sampling flow rate Ambient air was collected at 1 L / min for 20 min. After sampling, put plastic caps on both ends of the adsorption tube.

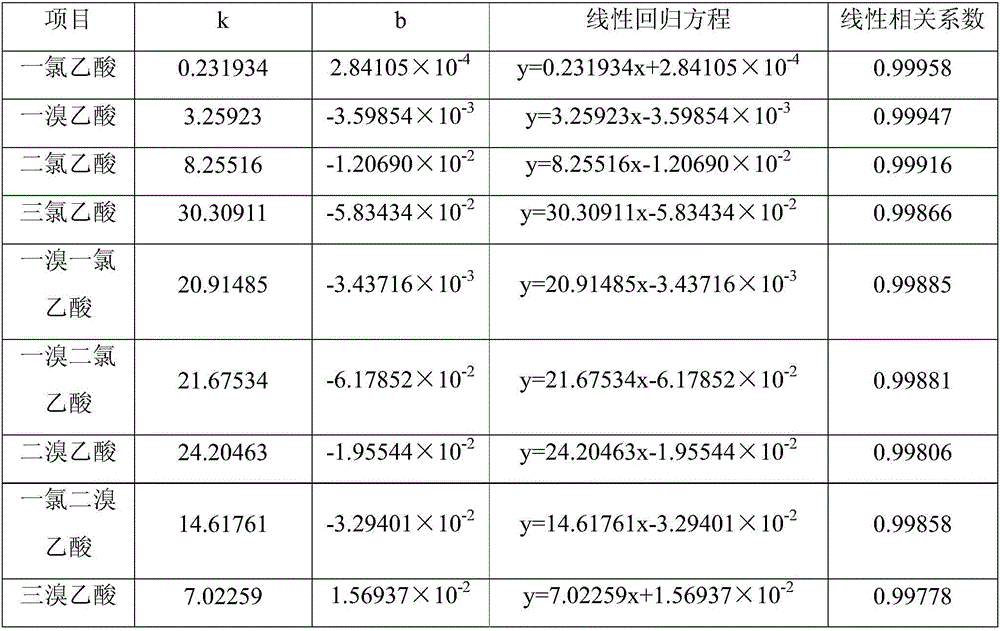

[0068] The concentration is 0.001mg / m3 prepared by diffusion dynamic gas distribution method 3 , 0.002mg / m 3 , 0.01mg / m 3 , 0.02mg / m 3 , 0.04mg / m 3 , 0.1mg / m 3 , 0.2mg / m 3 , 0.4mg / m 3 , 1.0mg / m 3 , 4.0mg / m 3 Nine haloacetic acid standard samples pass through the two-stage adsorption tube at a certain gas recovery rate. Pour the two sections of packing at the front and back of the adsorption tube into a stoppered test tube, add 5mL of water as a desorption reagent, cover the bottle with a stopper, and put it into an ultrasonic instrume...

Embodiment 2

[0077] Use an adsorption tube (200 mg at the front end and 100 mg at the end) equipped with silica gel filler to adsorb and collect the haloacetic acid compounds in the exhaust gas of the exhaust pipe of the pollution source. The gas flow rate is 0.4L / min, and the exhaust gas from pollution sources is collected for 50 minutes. After sampling, according to the sample analysis steps in Example 1, analyze and calculate the concentration of nine kinds of haloacetic acids in the exhaust gas of the pollution source exhaust pipe. The metal catalyst used for the drawing of the working curve and the determination of the samples to be tested is copper chloride, and the addition amount is 0.8 mg; and 0.1 ppm of tetraphenyliron porphyrin and 2 mg of benzenesulfonate phenolic resin (PAFR) are added.

[0078] The measurement results are as follows: monochloroacetic acid 0.3462mg / m 3 , monobromoacetic acid 0.2073mg / m 3 , dichloroacetic acid 0.1431mg / m 3 , Trichloroacetic acid 0.2315mg / m ...

Embodiment 3

[0080] Use an adsorption tube (200 mg at the front end and 100 mg at the end) equipped with silica gel filler to adsorb and collect haloacetic acid compounds in the air of the production workshop, open both ends of the adsorption tube at the sampling site, connect the adsorption tube to the atmospheric sampler, and set the gas sampling flow rate to Collect workshop air at 0.5L / min for 40 minutes. After sampling, according to the sample analysis steps in Example 1, analyze and calculate the concentrations of the nine kinds of haloacetic acids in the air of the production workshop. The metal catalyst used for the drawing of the working curve and the determination of the samples to be tested is ferric chloride, and the addition amount is 10 mg; and 6 ppm of p-chlorotetraphenylcopper porphyrin and 0.4 mg of benzenesulfonate phenolic resin (PAFR) are added.

[0081] The measurement results are as follows: monochloroacetic acid 0.0321mg / m 3 , Monobromoacetic acid 0.0213mg / m 3 , di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com