Graphene-based infrared transmission electromagnetic shielding filter, zinc sulfide window and fabrication method of graphene-based infrared transmission electromagnetic shielding filter

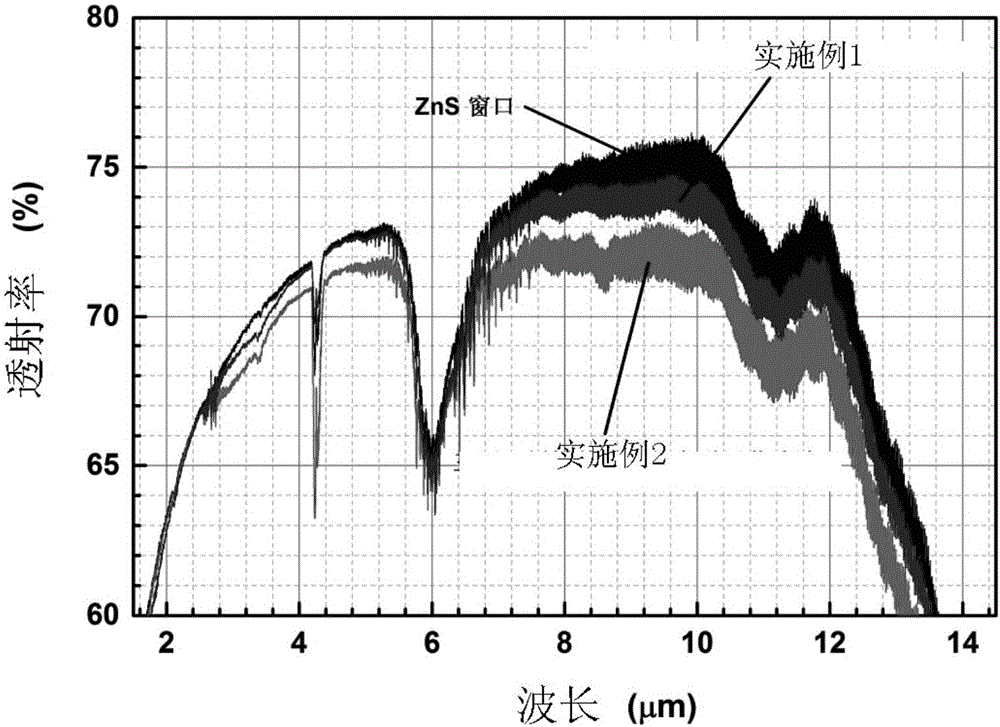

An electromagnetic shielding and graphene-based technology, applied in magnetic/electric field shielding, active shielding, circuits, etc., can solve the problems of complicated process, Moire interference fringes, low transmittance, etc., and achieve simple manufacturing process and suppress fading , the effect of high transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The embodiment of the present invention provides a method for preparing a graphene-based infrared transparent electromagnetic shielding filter, which includes the following steps:

[0033] Grow graphene film Gr on the surface of copper foil to obtain a copper foil / Gr composite;

[0034] Spray the polymer transition layer TL on the graphene film side of the copper foil / Gr composite, and obtain the copper foil / Gr / TL composite after curing;

[0035] Spray liquid PMMA (polymethyl methacrylate) on one side of the polymer transition layer of "copper foil / Gr / TL" structure, and obtain a copper foil / Gr / TL / PMMA composite after curing;

[0036] Etch off the copper foil to obtain a Gr / TL / PMMA composite;

[0037] Transfer the Gr / TL / PMMA complex to the inner surface of the zinc sulfide window to obtain the ZnS / Gr / TL / PMMA complex;

[0038] Place the ZnS / Gr / TL / PMMA composite in an organic solvent to dissolve the polymer transition layer and separate the PMMA carrier from the graphene film to obta...

Embodiment 1

[0046] (1) Wrap a 50μm thick high-purity copper foil on a quartz tube and place it in a tube furnace. In the furnace, pass high-purity H at a flow rate of 8 sccmm 2 , Adjust the air valve to keep the air pressure in the furnace at 25Pa, and heat up to 1000°C at a rate of 10°C / s, and keep it for 15min;

[0047] (2) Pass high purity CH into the tube furnace 4 , Keep the pressure in the furnace at 200Pa and react at a high temperature of 1050℃ for 20min. After the reaction, the temperature is reduced to room temperature at a rate of 10°C / s to obtain a copper foil / Gr composite;

[0048] (3) Use a glue spreader to spray a 12μm-thick polymer transition layer TL (transition layer) on the graphene film side of the copper foil / Gr composite, and obtain a copper foil / Gr / TL composite after curing; polymer transition The composition of the layer is as follows: phenolic resin and diazonaphthoquinone are mixed at a mass ratio of 1:1, and benzotriazole is added at 4% of the total mass of the pheno...

Embodiment 2

[0055] (1) Wrap a 50μm thick high-purity copper foil on a quartz tube and place it in a tube furnace. Pass high purity H into the furnace at a flow rate of 8sccmm 2 , Adjust the air valve to keep the air pressure in the furnace at 25Pa, and heat up to 1000°C at a rate of 10°C / s, and hold for 15min;

[0056] (2) Pass high purity CH into the tube furnace 4 , Keep the pressure in the furnace at 200Pa and react at a high temperature of 1050℃ for 20min. After the reaction, the temperature is reduced to room temperature at a rate of 10°C / s to obtain a copper foil / Gr composite;

[0057] (3) Use a glue applicator to spray a polymer transition layer with a thickness of 12 μm on the side of the copper foil / Gr composite graphene film, and then obtain a copper foil / Gr / TL composite after curing; the composition of the polymer transition layer is as follows: phenolic The resin and diazonaphthoquinone are mixed at a mass ratio of 1:1, and benzotriazole is added at 10% of the total mass of the ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com