Lithium ion battery positive electrode material additive, positive electrode material, positive electrode and battery

A lithium-ion battery and cathode material technology, applied in the field of applied chemistry, can solve problems such as the irreversible capacity of lithium-ion batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0033] Among them, the separator can be selected from various separators used in lithium-ion batteries known to those skilled in the art, such as polyolefin microporous membrane (PP), polyethylene felt (PE), glass fiber felt or ultrafine glass fiber paper or PP / PE / PP. As a preferred embodiment, the separator is PP / PE / PP.

[0034] The electrolyte contains lithium salt and non-aqueous solvent. The lithium salt can be lithium hexafluorophosphate, lithium tetrafluoroborate, lithium hexafluoroarsenate, lithium perchlorate, lithium trifluoromethanesulfonate, lithium perfluorobutylsulfonate, aluminate One or more of lithium, lithium chloroaluminate, lithium fluorosulfonyl imide, lithium chloride and lithium iodide; the non-aqueous solvent can be γ-butyrolactone, ethyl methyl carbonate, methyl propyl carbonate , dipropyl carbonate, acid anhydride, N-methylpyrrolidone, N-methylformamide, N-methylacetamide, acetonitrile, N,N-dimethylformamide, sulfolane, dimethylsulfoxide, disulfite ...

Embodiment 1

[0039] Will Li 2 CO 3 、MoO 3 and B 2 o 3 Mix according to the molar ratio of 1:0.97:0.02, put it in a stirring ball mill, mix and grind for 8 hours; press the precursor prepared by fully mixing and grinding on a tablet machine, and then put it in a corundum crucible; put the crucible in a box furnace , start heating from room temperature at a heating rate of 5°C / min, heat to 700°C and bake for 10h, then cool naturally to room temperature to obtain Li 2 Mo 0.97 B 0.04 o 3.97 . Will Li 2 Mo 0.97 B 0.04 o 3.97 Put it in a corundum crucible, put the crucible into a tube furnace, and feed 10% H 2 / Ar mixed gas, heating from room temperature at a heating rate of 5 °C / min, heating to 900 °C and roasting for 10 h, then naturally cooling to room temperature to obtain Li 2 Mo 0.97 B 0.04 o 3 sample.

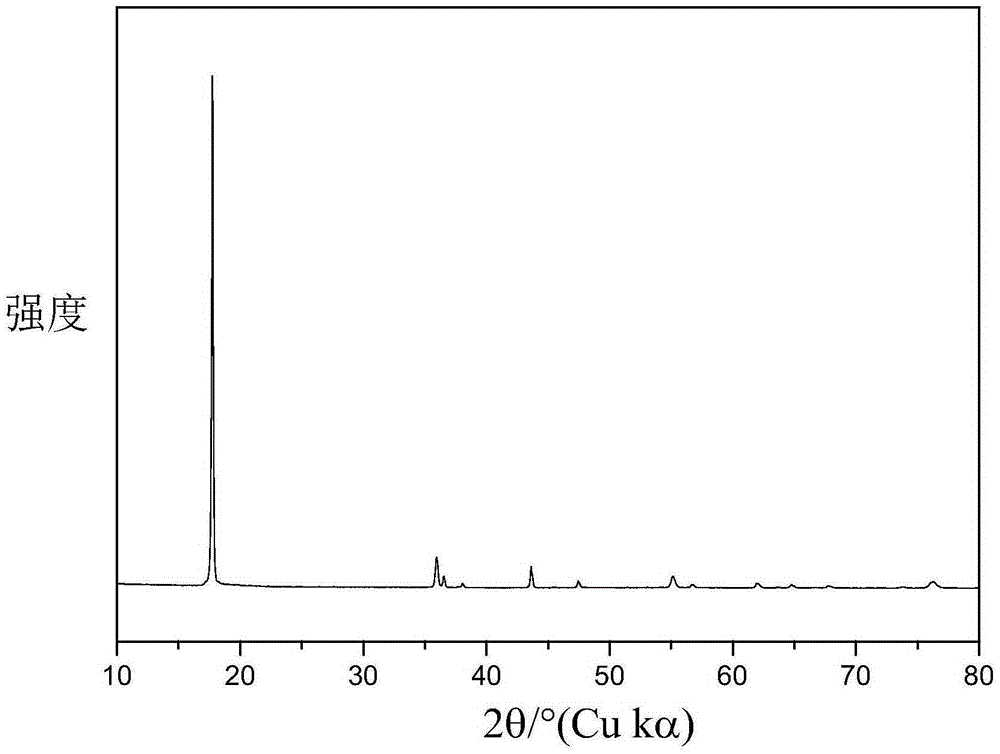

[0040] The prepared Li 2 Mo 0.97 B 0.04 o 3 The sample was analyzed by X-ray diffraction, and Li 2 Mo 0.97 B 0.04 o 3 The XRD spectrum of figure 1 .

Embodiment 2

[0042] LiOH, MoO 3 and H 3 BO 3 Mix according to the molar ratio of 2:0.925:0.1, place in a stirring ball mill, mix and grind for 6 hours; press the precursor prepared by fully mixing and grinding on a tablet machine, and then place it in a corundum crucible; put the crucible in a box furnace , start heating from room temperature with a heating rate of 5 °C / min, heat to 600 °C and bake for 20 h, then cool naturally to room temperature to obtain Li 2 Mo 0.925 B 0.1 o 3.925 . Will Li 2 Mo 0.925 B 0.1 o 3.925 Put it in a corundum crucible, put the crucible into a tube furnace, and feed 10% H 2 / Ar mixed gas, heating from room temperature at a heating rate of 5 °C / min, heating to 900 °C and then roasting for 30 h, then naturally cooling to room temperature to obtain Li 2 Mo 0.925 B 0.1 o 3 sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com