Nerve conduit and preparation method thereof

A nerve conduit and tube technology, applied in the field of neurosurgery, can solve the problems of low mechanical strength of the nerve conduit, failure to meet the needs of use, poor mechanical properties of the conduit, etc., and achieve the effects of strong flexibility, easy processing, and long degradation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] This embodiment provides a preparation method of a nerve guide, which includes:

[0018] S1: The polymer material is dissolved in an organic solvent, and the polymer solution is obtained after settling to remove air bubbles.

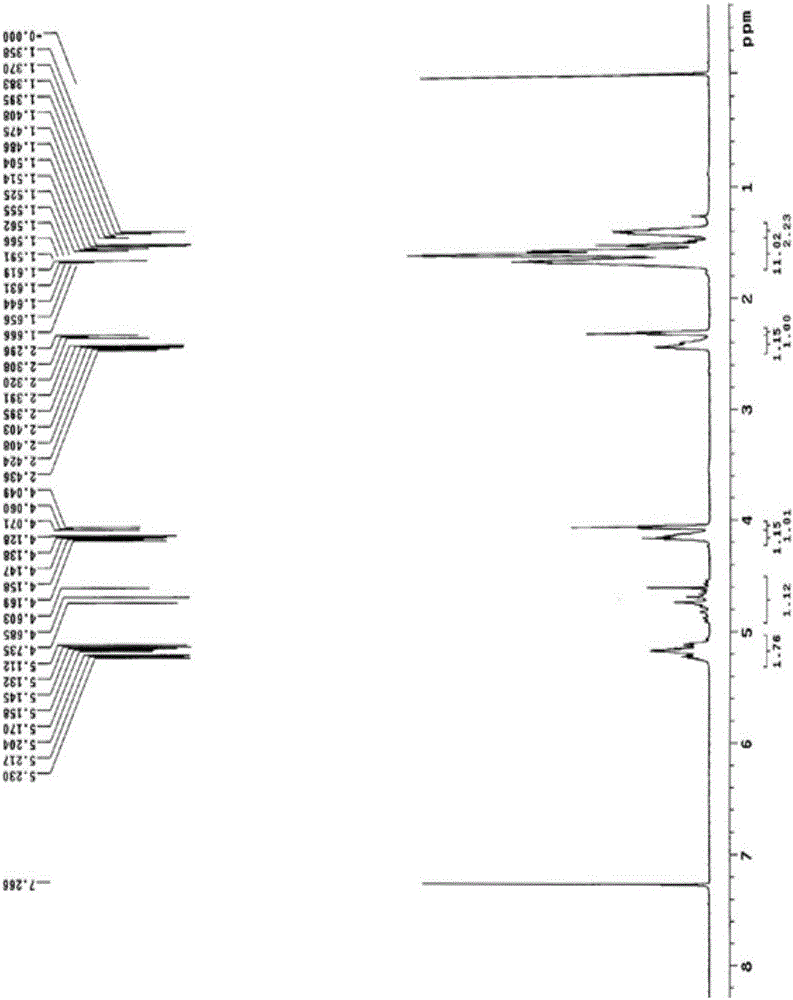

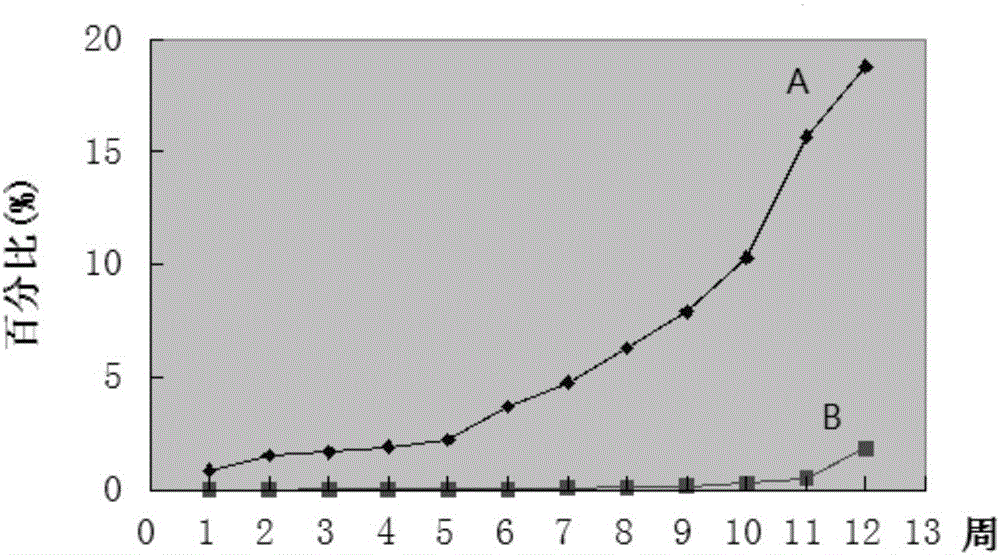

[0019] The content of the lactic acid monomer in the polymer material in this embodiment is 45-65 mol%, the content of the glycolic acid monomer is 5-20 mol%, and the content of the caprolactone monomer is 30-45 mol%. This polymer material is composed of lactic acid, glycolic acid and caprolactone, and is obtained by copolymerizing lactide, glycolide and caprolactone in a specific ratio. This polymer material has a large relative molecular weight, high mechanical strength, strong flexibility, and low expansion, and can be used for regeneration and repair of human tissue. Moreover, this polymer material has a long degradation cycle, and its degradation time in an in vitro environment is about It is 1.5 years, and the degradation time in the in viv...

Embodiment 11

[0054] This embodiment provides a kind of nerve guide, and its preparation method is:

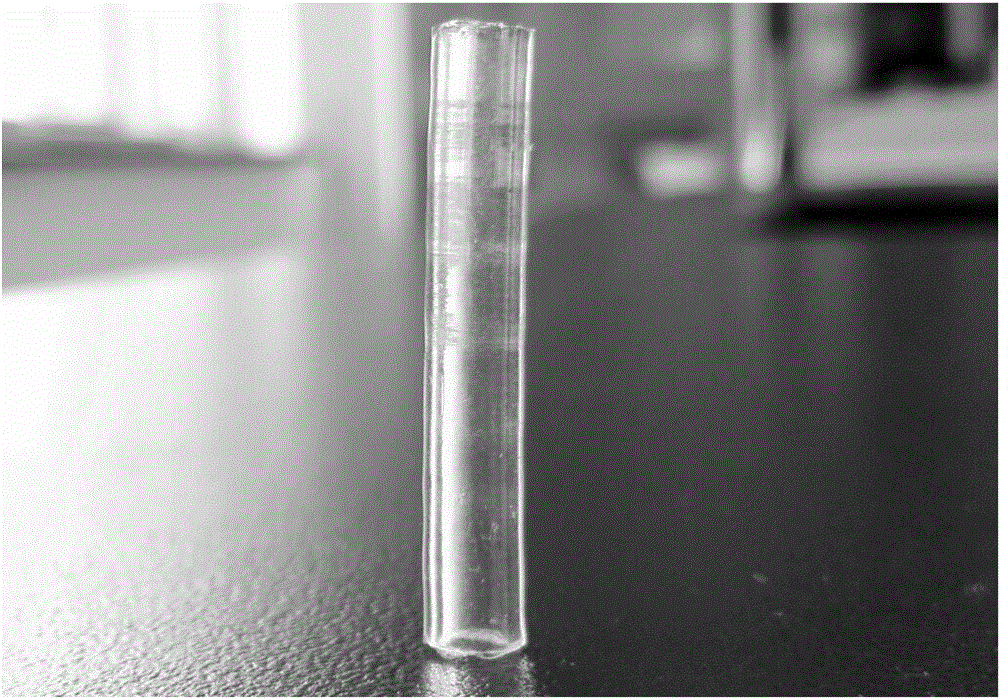

[0055] Take the polymer material provided in Example 6, dissolve it with chloroform, and prepare a polymer solution with a mass fraction of 5% of the polymer material. After standing to remove air bubbles, the polymer solution is evenly coated with a syringe. Horizontally rotate 50rpm on a rod-shaped mold with a diameter of 5mm. After the coating is completed, quickly evaporate the solvent at 150rpm. Continue to repeat this step 30-40 times. The tube was removed from the mold, and vacuum-dried at 50° C. for 3 days to obtain a nerve guide, the specifications of which were: tube inner diameter 5.1 mm, length 3 cm, thickness 0.5 mm.

Embodiment 12

[0057] This embodiment provides a kind of nerve guide, and its preparation method is:

[0058] Take the polymer material provided in Example 6, dissolve it with tetrahydrofuran, and prepare a polymer solution with a mass fraction of the polymer material of 8%. After standing still to remove air bubbles, use a syringe to evenly coat the polymer solution until it rotates horizontally 50rpm, diameter of 5mm rod-shaped mold, after the coating is completed, quickly evaporate the solvent at 200rpm, after the solvent is evaporated, continue to repeat this step 10-20 times, until the pipe has a certain thickness, soak the pipe with absolute ethanol Take it off from the mold, and dry it under vacuum at 40° C. for 5 days to obtain a nerve guide, the specifications of which are: tube inner diameter 5.0 mm, length 3 cm, thickness 0.3 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com