Preparation method of antibacterial and hydrophobic biodegradable membrane

A degradable membrane and hydrophobic technology, applied in the field of composite membrane, can solve the problems of insignificant bacteriostatic effect, poor water resistance, poor mechanical properties, etc., and achieve good biodegradability, simple reaction operation, and elimination of acid corrosion loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The modified chitosan used in the following examples was prepared according to the following steps:

[0046] In a 100 mL single-necked flask were added 20 g of ionic liquid 1-butyl-3-methylimidazole bromide and 0.5 g of chitosan with a viscosity of 300 mPa.s. The chitosan was pretreated with hydrobromic acid. It is made by freeze-drying. The single-necked flask is evacuated and sealed. Under the condition of 0.06 MPa negative pressure, it is stirred evenly, and it is placed in an oil bath at 100 ℃ and stirred for 4 h at a constant temperature. After observing the complete dissolution of chitosan through a polarizing microscope, add 2,3-epoxypropyl with n (alkyl quaternary ammonium salt): n (chitosan) of 6:1 and epoxy equivalent of 0.85 to the one-necked flask Trimethylammonium chloride (GTMAS), re-maintain the negative pressure of 0.06 MPa and place the single-neck flask in an oil bath at 80 ℃ for constant temperature reaction for 8 hours to ensure the full reaction of chi...

Embodiment 2

[0051] Weigh a certain amount of HTCC powder and CMC powder with a degree of substitution of 0.56, respectively add a certain amount of deionized water to them, swell at a constant temperature in a water bath at 60 ℃ for a certain period of time, then stir until uniform, and place at room temperature after stirring. After 24 h, the HTCC solution with a mass fraction of 2% and the CMC solution with a mass fraction of 2% were finally obtained respectively;

[0052] Weigh the above configured HTCC solution and CMC solution at a solute mass ratio of 0.5:10, and mix them in a water bath at 25 ℃ to obtain a uniform HTCC / CMC aqueous solution, and then pour the mixed solution into the membrane tool to make the mixed solution The thickness of the HTCC / CMC composite film is as uniform as possible and placed in a blast drying oven at 45 ℃ for 24 hours. After the solvent is completely evaporated, a dry HTCC / CMC composite film is obtained.

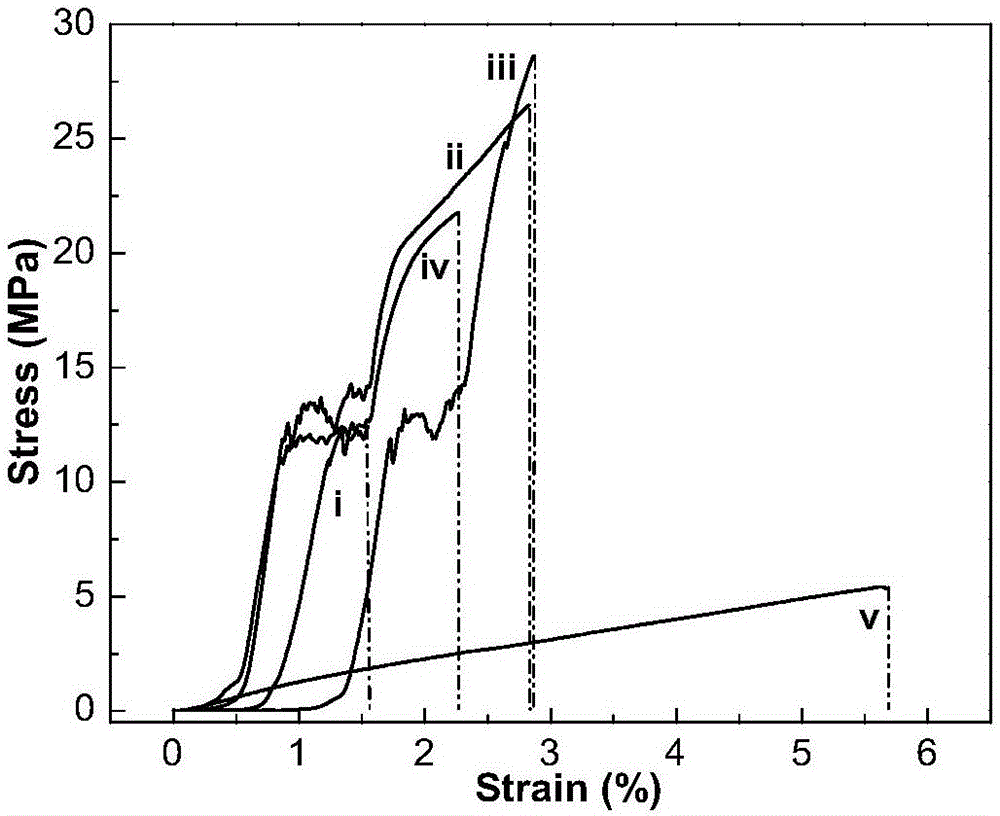

[0053] The composite film prepared in this example ha...

Embodiment 3

[0055] The implementation conditions and steps are the same as in Example 2, except that the solute mass ratio of the configured HTCC solution to the CMC solution is replaced with 1:10.

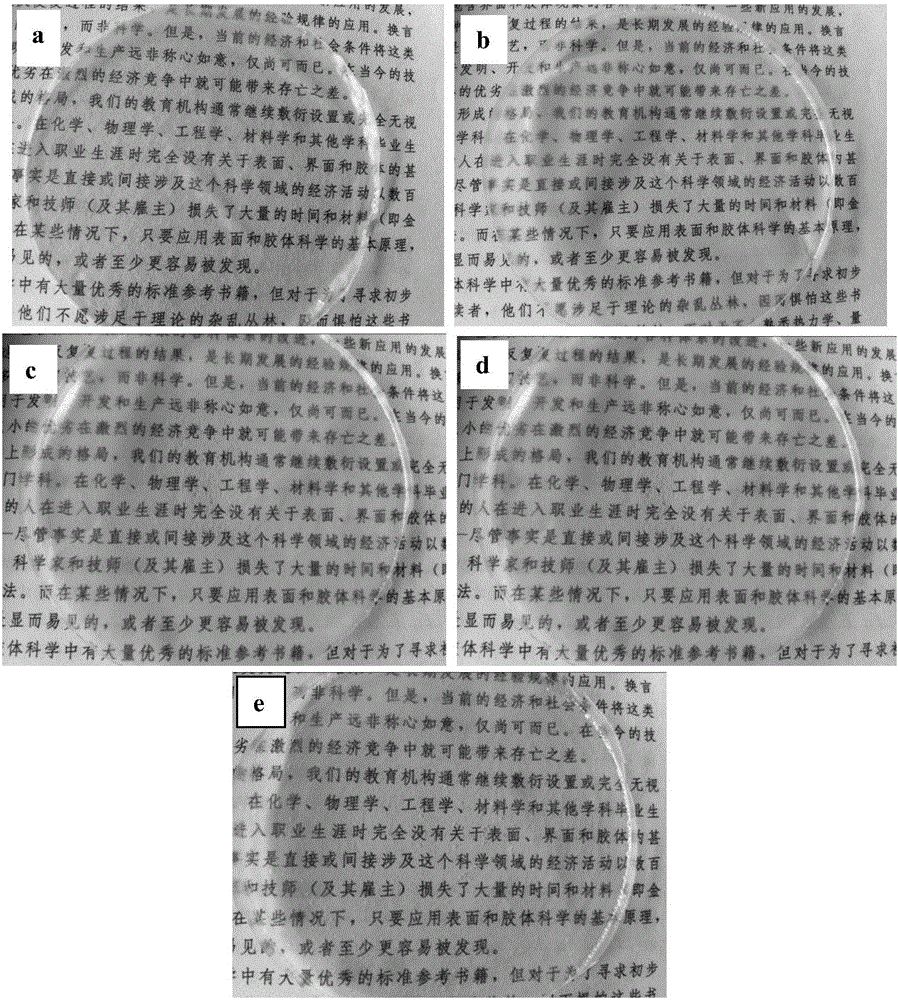

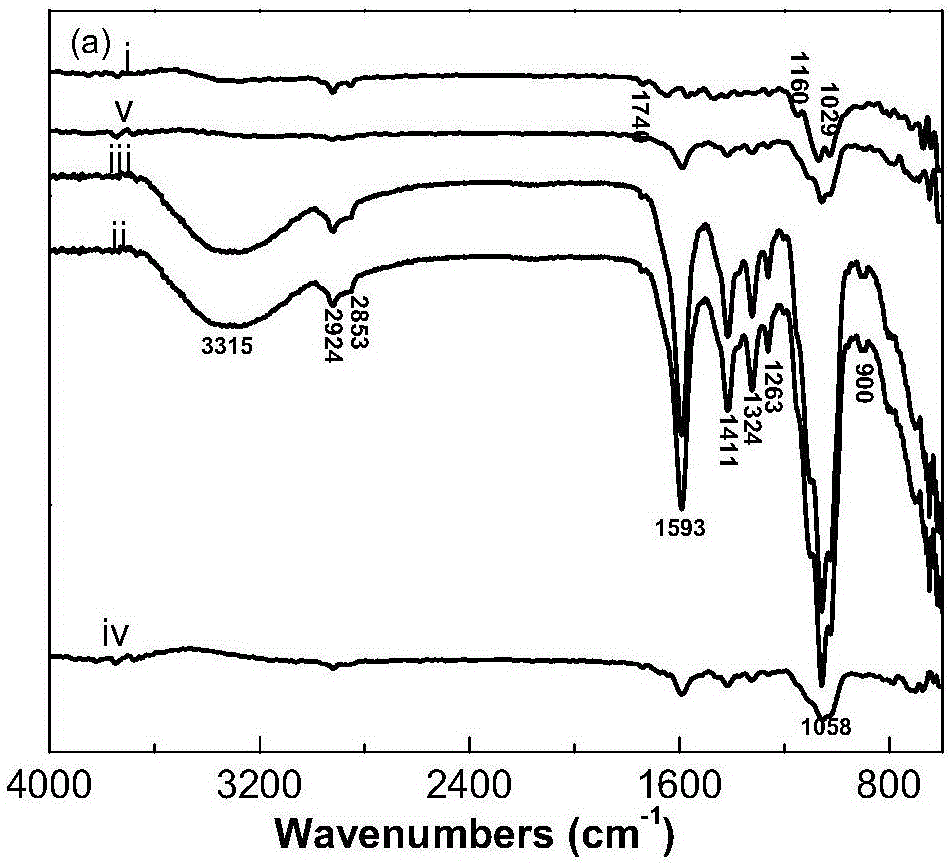

[0056] The composite film prepared in this example has good light transmittance. The cut surface of the film and the Fourier change infrared spectrum show that there is good compatibility and significant interaction between HTCC molecules and CMC molecules in the composite film; The tensile strength of the film is 28.56 MPa, which is 139% higher than that of the pure CMC film; the elongation at break is 2.86%; the contact angle of water in the composite film is 90 o , Greater than the contact angle of pure CMC membrane, showing good hydrophobicity; HTCC / CMC composite membrane has a diameter of 1.28 cm for Staphylococcus aureus and 1.03 cm for E. coli.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com