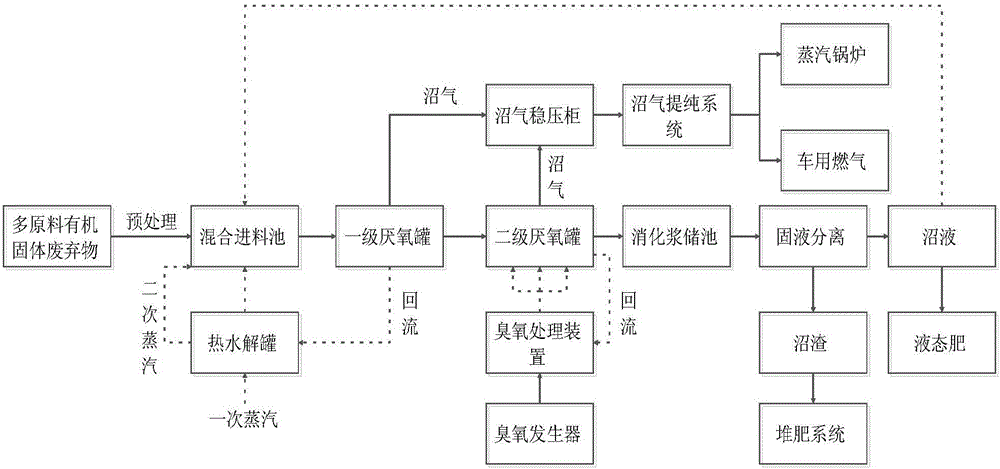

Reinforced multi-raw-material two-stage fully-mixed anaerobic digestion methane production method

A technology of anaerobic digestion and biogas production, which is applied in the direction of waste fuel, biological sludge treatment, sludge treatment, etc., can solve the problems of low gas production rate and low material degradation efficiency, so as to increase the solid content of the feed and reduce the heat energy Loss, the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Livestock manure, rice straw, excess sludge, and kitchen waste are subjected to conventional pretreatment, among which, the livestock manure is homogenized to remove sand, the rice straw is crushed to less than 1cm, and the remaining sludge is homogenized to remove sand. Garbage is mechanically sorted, degreased, pulverized and pulped. After pretreatment, the TS ratio of poultry manure, rice straw, remaining sludge, and kitchen waste is: poultry manure: rice straw: remaining sludge: Food waste = 1:3:0.25:0.25 is sent to the feeding tank for mixing, and the solid content of the mixed material is adjusted to 8% by using reflux biogas slurry, and the secondary steam generated by the thermal hydrolysis process is heated by the steam in the mixing feeding tank The coil preheats the mixed material and mixes it with the high-temperature material from thermal hydrolysis, so that the preheating temperature of the total mixed material reaches 35°C, and the mixing preheating reside...

Embodiment 2

[0047] Livestock manure, rice straw, excess sludge, and kitchen waste are subjected to conventional pretreatment, among which, the livestock manure is homogenized to remove sand, the rice straw is crushed to less than 1cm, and the remaining sludge is homogenized to remove sand. Garbage is mechanically sorted, degreased, pulverized and pulped. After pretreatment, the TS ratio of poultry manure, rice straw, remaining sludge, and kitchen waste is: poultry manure: rice straw: remaining sludge: Food waste = 1:3:0.25:0.25 is sent to the feeding tank for mixing, and the solid content of the mixed material is adjusted to 10% by using reflux biogas slurry, and the secondary steam generated by the thermal hydrolysis process is heated by the steam in the mixing feeding tank The coil preheats the mixed material and mixes it with the high-temperature material from thermal hydrolysis, so that the preheating temperature of the total mixed material reaches 36°C, and the mixing preheating resid...

Embodiment 3

[0054] Livestock manure, rice straw, excess sludge, and kitchen waste are subjected to conventional pretreatment, among which, the livestock manure is homogenized to remove sand, the rice straw is crushed to less than 1cm, and the remaining sludge is homogenized to remove sand. Garbage is mechanically sorted, degreased, pulverized and pulped. After pretreatment, the TS ratio of poultry manure, rice straw, remaining sludge, and kitchen waste is: poultry manure: rice straw: remaining sludge: Food waste = 1:3:0.5:0.5 enters the mixed feeding tank for mixing, uses the reflux biogas slurry to adjust the solid content of the mixed material to 12%, and uses the secondary steam generated by the thermal hydrolysis process to heat through the steam in the mixed feeding tank The coil preheats the mixed material and mixes it with the high-temperature material from thermal hydrolysis, so that the preheating temperature of the total mixed material reaches 36°C, and the mixing preheating resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com