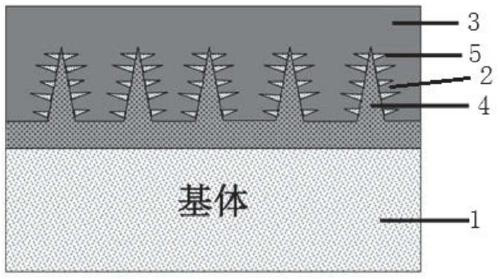

A method for inhibiting the growth of tin whiskers based on micro-nano needle cone structure

A structural suppression, micro-nano technology, applied in the direction of superimposed layer plating, coating, semiconductor devices, etc., can solve the problems of not forming a universally applicable mechanism, thermodynamic driving force cannot be eliminated, bridging, etc., to achieve the formation of suppression, Difficult to disengage and the effect of reducing the driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

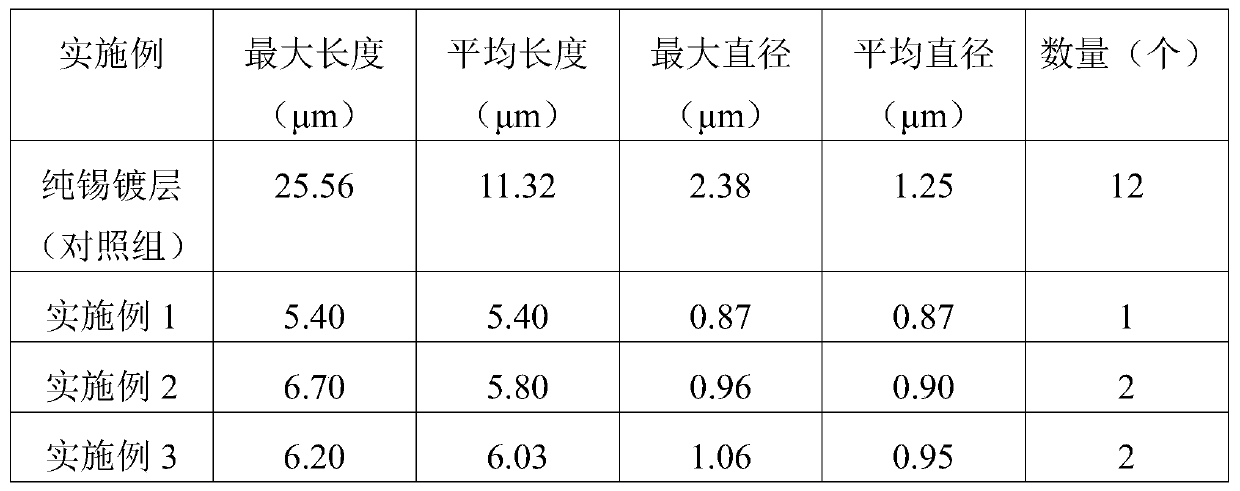

Embodiment 1

[0036] Select the lead frame C194 copper alloy as the conductive substrate, degrease the conductive substrate for 20s, the degreasing temperature is 40°C, the degreasing current is 3ASD (A / dm2), after cleaning with deionized water, wash with 20% dilute sulfuric acid for 20s, and then Rinse with deionized water; place the cleaned target substrate in the prepared plating solution at a temperature of 55°C, chemically deposit micron copper needles on the conductive substrate for 20 minutes, and obtain a copper needle structure with a length of about 5 μm. After cleaning with deionized water, put it in the nickel-plated needle plating solution, the solution temperature is 50°C, the current density is 1.2ASD, the plating time is 10min, and the nickel nano-micro cone with a length of about 500nm is obtained by electrodeposition on the micron copper needle. structure. Utilize 20% dilute sulfuric acid to pickle the obtained micro-nano needle cone structure to remove the oxide layer tha...

Embodiment 2

[0038] Select stainless steel as the conductive substrate, degreasing the conductive substrate for 30s, degreasing temperature 40°C, degreasing current 4ASD (A / dm2), after cleaning with deionized water, wash with 20% dilute sulfuric acid for 20s, and then rinse with deionized water Clean; placed in the nickel-plated needle plating solution, the solution temperature is 50°C, the current density is 1.0ASD, the electrodeposition time is 20min, and the nickel nanocone structure with a length of about 700nm is obtained by electrodeposition. Utilize 20% dilute sulfuric acid to pickle the obtained micro-nano needle cone structure to remove the oxide layer that may be exposed to the air, and then place it in a tin plating solution. The temperature of the plating solution is 25 ° C, and the current density is 1.2ASD. The electroplating time is 5 minutes, the thickness of the tin layer is about 2 μm, and the tin layer is cleaned and dried after electroplating.

Embodiment 3

[0040]Select semiconductor silicon as the substrate, first sputter a layer of 50 / 500nm Cr / Cu seed layer on the silicon substrate, wash it with 20% dilute sulfuric acid for 20s, and then rinse it with deionized water; place it in the nickel-plated needle plating solution, The temperature of the solution is 50° C., the current density is 1.0ASD, and the electrodeposition time is 20 minutes. A nickel nanocone structure with a length of about 700 nm is obtained by electrodeposition. Utilize 20% dilute sulfuric acid to pickle the obtained micro-nano needle cone structure to remove the oxide layer that may be exposed to the air, and then place it in a tin plating solution. The temperature of the plating solution is 25 ° C, and the current density is 1.2ASD. The electroplating time is 5 minutes, the thickness of the tin layer is about 2 μm, and the tin layer is cleaned and dried after electroplating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com