Three-dimensional heterojunction-structured nickel cobalt sulfide electrode material and preparation method and application thereof

A technology of cobalt-nickel sulfide and heterostructure, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., to achieve the effects of favorable charge transmission, stable performance, and excellent supercapacitor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Put the carbon paper in a mixed methanol solution of 0.5mol / L thiourea and 0.0.08mol / L sodium sulfide in advance to react at 180°C for 2h, then take it out and wash it with deionization, and dry it at 90°C for 10h to obtain sulfur doping Modified carbon paper support.

[0028] 2. Add 0.42mol / L of Co(NO 3 ) 2 ·6H 2 O, 0.21mol / L Ni(NO 3 ) 2 ·6H 2 O and 0.9mol / L of thiourea were dissolved in methanol, stirred and mixed evenly, and then transferred to the autoclave. At the same time, a sulfur-doped modified carbon paper carrier was placed in the autoclave, and the autoclave was sealed and placed in Reaction at 180°C for 4h.

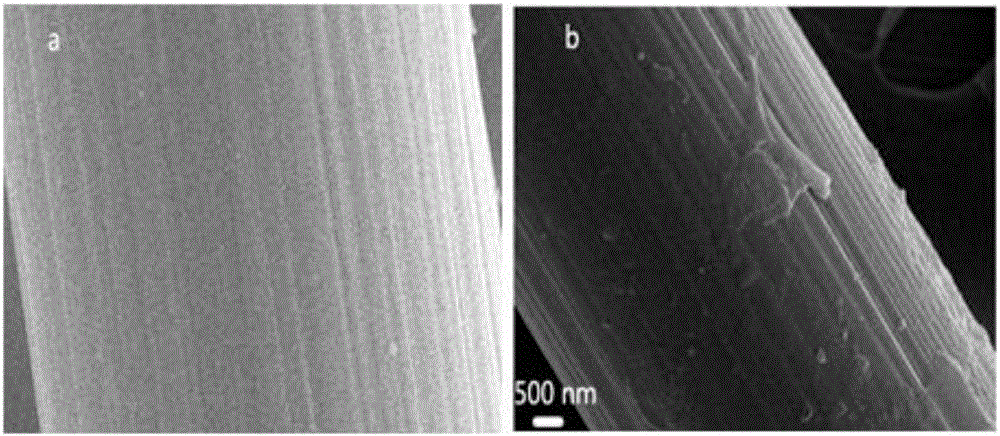

[0029] 3. Take out the carbon paper, wash it with deionized water, and dry it at 90°C for 10 hours to obtain the NiCo loaded with carbon paper as the electrode carrier. 2 S 4 Active component electrode material. figure 1 SEM images of the carbon paper carrier before and after sulfur modification. in, figure 1 (a) is the SEM image of unmod...

Embodiment 2

[0031] 1. Put the carbon cloth in a mixed methanol solution of 0.5mol / L thiourea and 0.1mol / L sodium chloride in advance to react at 180°C for 2h, then take it out and wash it with deionization, and dry it at 80°C for 12h to obtain sulfur doping Modified carbon cloth support.

[0032] 2. Add 0.28mol / L of Co(NO 3 ) 2 ·6H 2 O, 0.14mol / L Ni(NO 3 ) 2 ·6H 2 O and 0.6mol / L of thiourea were dissolved in water, stirred and mixed evenly, and then transferred to the autoclave. At the same time, a sulfur-doped modified carbon cloth carrier was placed in the autoclave, and the autoclave was sealed and placed at 180 ℃ reaction 2h.

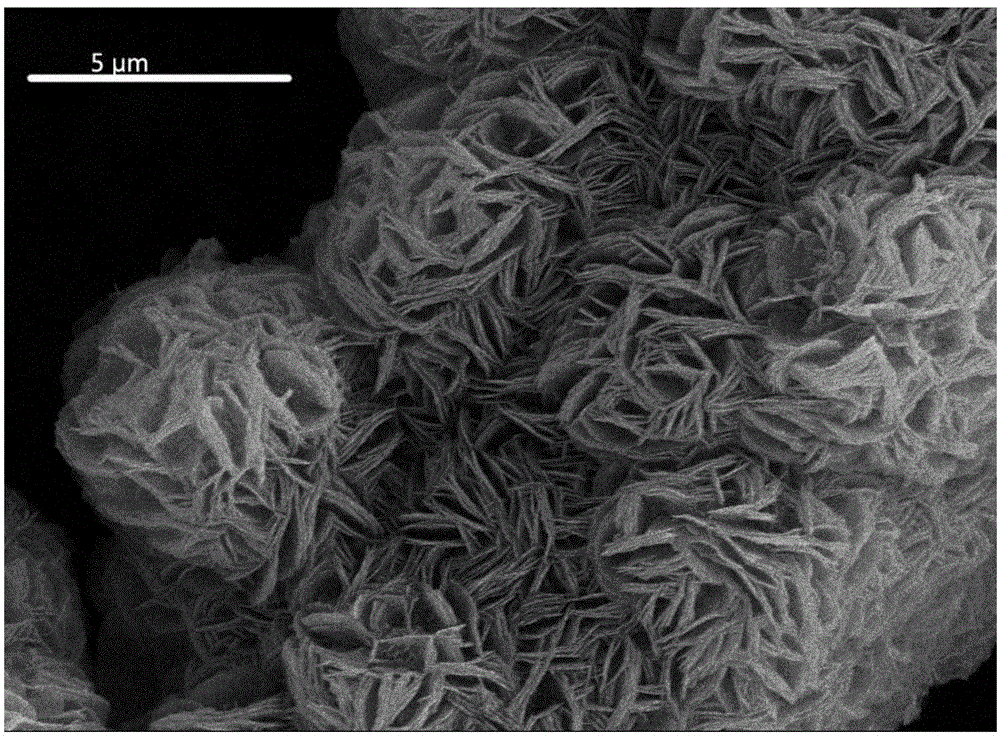

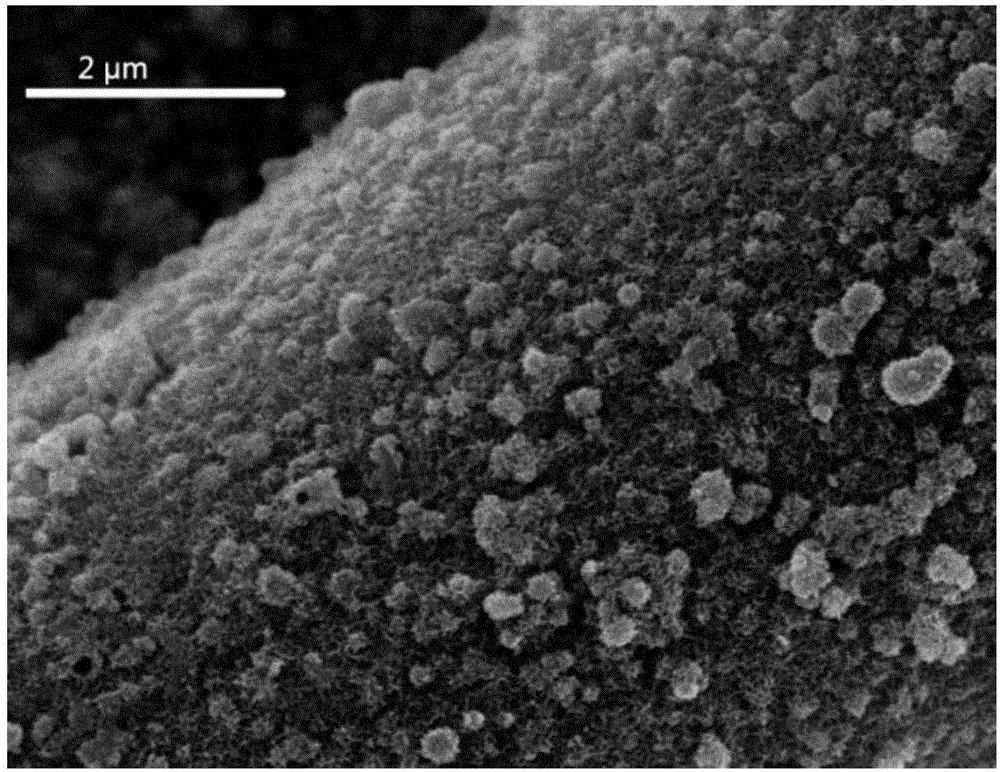

[0033]3. Take out the carbon cloth, wash it with deionized water, and dry it at 80°C for 12 hours to obtain the NiCo loaded with sulfur-doped modified carbon cloth as the electrode carrier. 2 S 4 electrode material. figure 2 For the NiCo prepared in Example 2 2 S 4 SEM image. From figure 2 It can be seen that the prepared NiCo 2 S 4 The materia...

Embodiment 3

[0035] 1. Pre-place the carbon paper in a mixed ethanol solution of 0.8mol / L thiourea and 0.12mol / L sodium sulfide at 120°C for 8h, then take it out and wash it with deionization, and dry it at 60°C for 16h to obtain the sulfur-doped modification. permanent carbon paper carrier.

[0036] 2. Add 0.14mol / L of CoCl 2 ·6H 2 O, 0.07mol / L NiCl 2 ·6H 2 O and 0.3mol / L thioacetamide were dissolved in methanol, stirred and mixed evenly, and then transferred to an autoclave, and a sulfur-doped modified carbon paper carrier was placed in the autoclave at the same time, and the autoclave was sealed. Placed at 220°C for 1h.

[0037] 3. Take out the carbon paper, wash it with deionized water, and dry it at 60°C for 16 hours to obtain the NiCo loaded with sulfur-doped modified carbon paper as the electrode carrier. 2 S 4 electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com