Flue gas desulfurization treatment technology by utilizing hydrogen peroxide method and desulfurization treatment system of flue gas desulfurization treatment technology

A hydrogen peroxide method and treatment process technology, applied in the field of flue gas desulfurization, can solve the problems of unstable ammonium sulfite, incomplete oxidation, secondary pollution, etc., achieve strong activity, less supporting equipment, and save investment costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

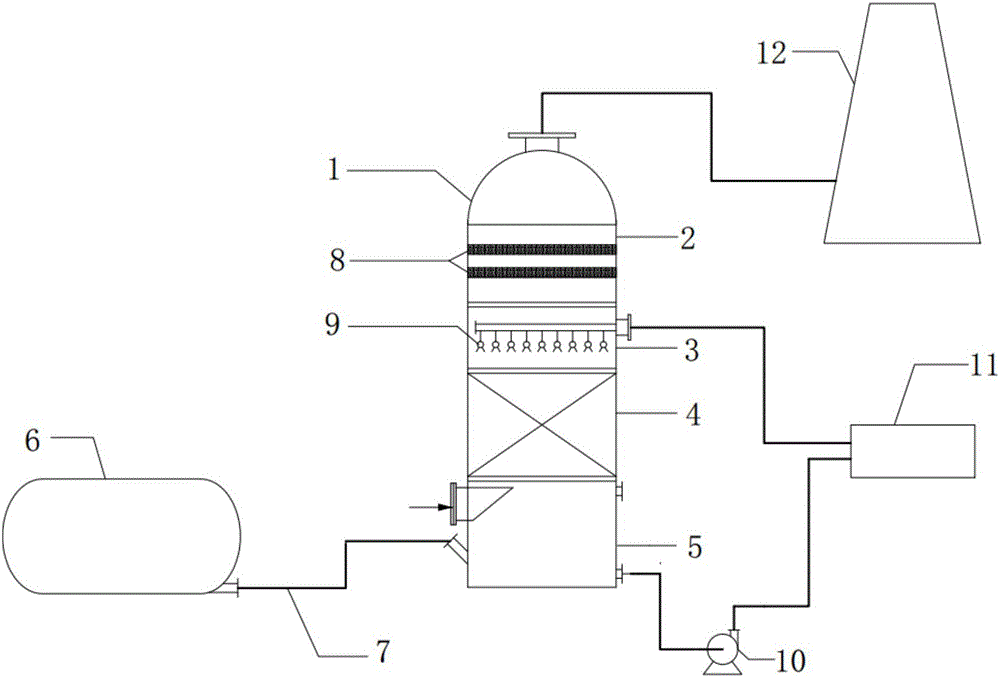

[0044] This embodiment according to figure 1 The structure of the desulfurization treatment system is connected with each instrument and equipment, and the operation is carried out according to the above-mentioned desulfurization treatment process steps and the parameters; the entire operation process is controlled by a control system of a programmable logic controller (PLC), and the control room does not need to be equipped with conventional monitoring equipment , The monitoring and control of the device are all realized by PLC.

[0045] The sulfur dioxide content of the sulfuric acid tail gas intake in this embodiment is 1600mg / Nm 3 , adjust the temperature of sulfuric acid tail gas to be 60°C, the inlet pressure to be 1500Pa, and the oxygen content to be 4%. Through theoretical calculation and in conjunction with the concentration of the hydrogen peroxide solution absorbent used in the test, it is determined to be 0.1-1.0%. The hydrogen peroxide solution used in this embodi...

Embodiment 2

[0055] This embodiment also presses figure 1 The shown structure is connected to each instrument and equipment, and the instrument and equipment used are the same as in Example 1, and the operation process and steps are also the same as in Example 1. The difference from Example 1 is that the inlet temperature of the sulfuric acid tail gas is 70 ° C. The hydrogen peroxide solution absorbent concentration is 0.5% in the absorption layer 4 of the reaction absorption tower 1, and the sulfuric acid concentration in the absorption layer remains on 25%, and other used parameters are all identical with embodiment 1. After being treated by the desulfurization system, the concentration of sulfur dioxide is less than 200mg / Nm 3 , The desulfurization rate is greater than 98%.

Embodiment 3

[0057] This embodiment also presses figure 1 The shown structure is connected to each instrument and equipment, and the instrument and equipment used, the operation process and the steps are the same as in Example 1, the difference is that the inlet temperature of the sulfuric acid tail gas is 80 ° C, and the peroxidation in the absorption layer 4 of the reaction absorption tower 1 The hydrogen solution absorbent concentration is 1%, and the sulfuric acid concentration in the absorption layer 4 is maintained at 30%. After being treated by the desulfurization system, the concentration of sulfur dioxide is less than 200mg / Nm 3 , The desulfurization rate is greater than 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com