A kind of magnetic nanoparticle modified by phenylboronic acid and its preparation method and application

A magnetic nanoparticle and nanoparticle technology, applied in the field of nanomaterials, can solve the problems of cumbersome process, high material consumption and energy consumption, limiting fructose, etc., and achieve the effects of optimized synthesis steps, rapid separation, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

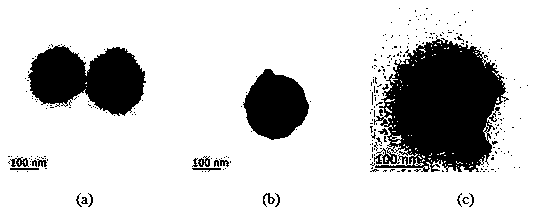

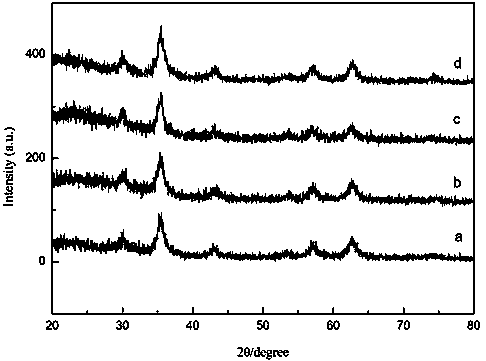

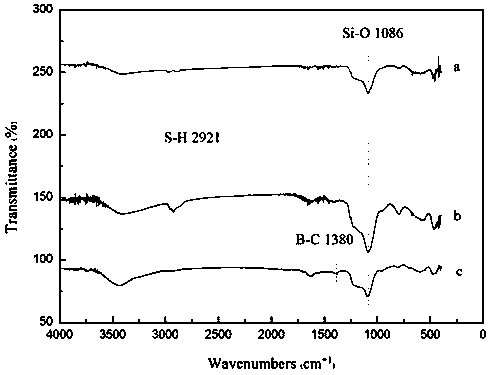

[0043] Example 1: Synthesis of novel phenylboronic acid functionalized magnetic microspheres

[0044] (1) Ferric oxide nanoparticles (Fe 3 o 4 NPs) synthesis

[0045] 0.9 g FeCl 3 ·6H 2 O, 2.890 g NH 4 AC and 0.3 g of trisodium citrate dihydrate were dissolved in a single-necked flask filled with 60 mL of ethylene glycol, and the system was placed in an oil bath at 80 °C for 0.5 h, and a black uniform system was finally obtained. Then the homogeneous system was transferred to a stainless steel autoclave, stirred evenly, reacted at 180 °C for 12 h, cooled to room temperature, separated the black product and washed several times with absolute ethanol, and dried in a vacuum oven for 24 h.

[0046] (2) Preparation of magnetic silica nanoparticles (Fe 3 o 4 @SiO 2 NPs):

[0047] Weigh 0.2 g Fe 3 o 4 NPs were dispersed in 5 mL of dilute hydrochloric acid (0.1 M), and the system was ultrasonically separated for 5 min. The obtained solid was washed several times with di...

Embodiment 2

[0052] Example 2: Synthesis of novel phenylboronic acid functionalized magnetic microspheres

[0053] (1) Ferric oxide nanoparticles (Fe 3 o 4 NPs) synthesis

[0054] 1.8 g FeCl 3 ·6H 2 O, 4.818 g NH 4 AC and 0.5 g of trisodium citrate dihydrate were dissolved in a single-necked flask containing 80 mL of ethylene glycol, and the system was placed in an oil bath at 120 °C and stirred for 2 h to obtain a black uniform system. Then the homogeneous system was transferred to a stainless steel high-pressure reactor, stirred evenly, reacted at 220 °C for 20 h, cooled to room temperature, separated the black product and washed several times with absolute ethanol, and dried in a vacuum oven for 24 h.

[0055] (2) Preparation of magnetic silica nanoparticles (Fe 3 o 4 @SiO 2 NPs):

[0056] Weigh 0.4 g Fe 3 o 4 NPs were dispersed in 15 mL of dilute hydrochloric acid (0.1 M), and the system was ultrasonically separated for 20 min before magnetic separation. The obtained sol...

Embodiment 3

[0061] Example 3: Synthesis of novel phenylboronic acid functionalized magnetic microspheres

[0062] (1) Ferric oxide nanoparticles (Fe 3 o 4 NPs) synthesis

[0063] 1.35g FeCl 3 ·6H 2 O, 3.854 g NH 4 AC and 0.4 g of trisodium citrate dihydrate were dissolved in a single-necked flask filled with 70 mL of ethylene glycol, and the system was placed in an oil bath at 100 ° C for 1 h, and a black uniform system was finally obtained. Then the homogeneous system was transferred to a stainless steel autoclave, stirred evenly, reacted at 200°C for 16 hours, cooled to room temperature, separated the black product and washed several times with absolute ethanol, and dried in a vacuum oven for 24 hours.

[0064] (2) Preparation of magnetic silica nanoparticles (Fe 3 o 4 @SiO 2 NPs):

[0065] Weigh 0.3g Fe 3 o 4 NPs were dispersed in 10mL of dilute hydrochloric acid (0.1M), and the system was ultrasonically separated for 10min by magnetic separation. The obtained solid was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com