Zirconium oxide ceramic cylinder sleeve material and preparation method thereof

A technology of zirconia ceramics and zirconia, which is applied in the field of ceramic materials, can solve problems such as unfavorable production and operation, increased service temperature, and high sintering temperature, and achieve the effects of reducing friction coefficient, improving wettability, and reducing sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

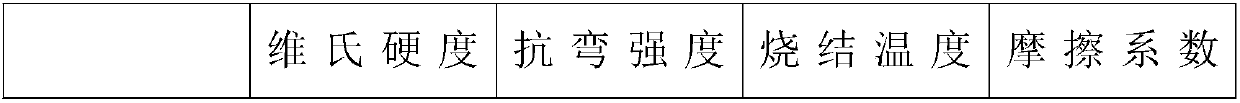

Image

Examples

Embodiment 1

[0027] A zirconia ceramic cylinder liner material, comprising the following raw materials:

[0028] Zirconia 80kg, yttrium oxide 4kg, neodymium oxide 3kg, graphite 3kg and molybdenum carbide 10kg.

[0029] The preparation method comprises the following steps:

[0030] 1) Pretreatment: Weighing graphite and molybdenum carbide according to the proportion, soaking them in 1mol / L dilute nitric acid for 30 minutes, and then separating solid and liquid to obtain pretreated graphite and molybdenum carbide;

[0031] 2) Ball mill powder: Weigh zirconia, 100 million oxide and neodymium oxide according to the ratio, and then mix them with pretreated graphite and molybdenum carbide and add them to the ball mill to form a mixed powder, and then add 1.4 kg methylcellulose and 1.4kg polymethacrylate, then start the ball mill to obtain the slurry;

[0032] 3) Granulation: Spray-dry the slurry obtained in step 2) in a granulation spray tower, remove the moisture therein to obtain granulated ...

Embodiment 2

[0037] A zirconia ceramic cylinder liner material, comprising the following raw materials:

[0038] 82kg of zirconia, 5kg of yttrium oxide, 4kg of neodymium oxide, 1kg of graphite and 8kg of molybdenum carbide, wherein the graphite and molybdenum carbide need to be soaked in dilute nitric acid first, and then separated from solid and liquid.

[0039] The preparation method of zirconia ceramic cylinder liner material comprises the following steps:

[0040] 1) Pretreatment: Weighing graphite and molybdenum carbide according to the ratio, soaking in 0.5mol / L dilute nitric acid for 40 minutes, and then separating solid and liquid to obtain pretreated graphite and molybdenum carbide;

[0041] 2) Ball milling powder: Weigh zirconia, 100 million oxide and neodymium oxide according to the proportion, then mix them with pretreated graphite and molybdenum carbide and add them to the ball mill to form a mixed powder, and then add 2kg to the mixed powder Methyl cellulose and 2kg polymeth...

Embodiment 3

[0047] A zirconia ceramic cylinder liner material, comprising the following raw materials:

[0048] Zirconia 79kg, yttrium oxide 5kg, neodymium oxide 4.5kg, graphite 4kg and molybdenum carbide 7.5kg.

[0049] The preparation method comprises the following steps:

[0050] 1) Pretreatment: Weighing graphite and molybdenum carbide according to the proportion, soaking them in 2mol / L dilute nitric acid for 25 minutes, and then separating solid and liquid to obtain pretreated graphite and molybdenum carbide;

[0051] 2) Ball milling powder: Weigh zirconia, 100 million oxide and neodymium oxide according to the proportion, and then mix them with pretreated graphite and molybdenum carbide and add them to the ball mill to form a mixed powder, and then add 2kg to the mixed powder Methylcellulose and 2kg polymethacrylic acid amine, then start the ball mill to obtain the slurry;

[0052] 3) Granulation: Spray-dry the slurry obtained in step 2) in a granulation spray tower, remove the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com