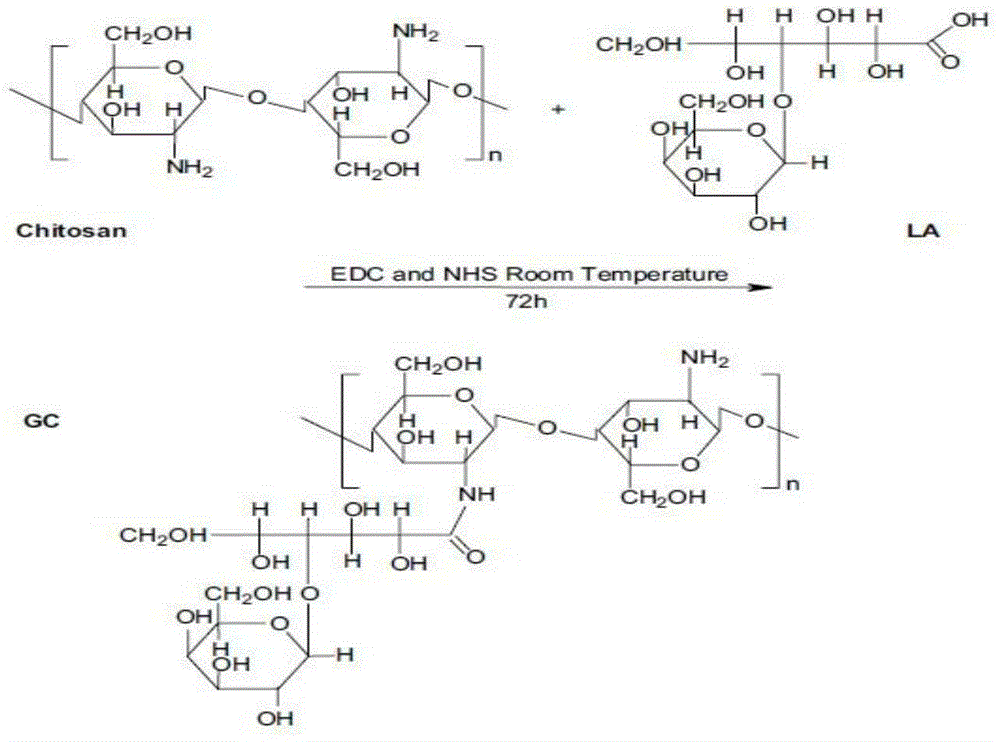

Alginate hydrogel microsphere carrier containing galactosyl chitosan molecule and application thereof

A hydrogel microsphere and chitosan-based technology, applied in the direction of fixing on/in the organic carrier, can solve the problems of affecting the medical effect of cell secretion products, poor sphericity, waste of raw materials, etc., to maintain immunity The effects of isolation performance, good mechanical strength, and excellent sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Preparation of sodium alginate solution: 2.0 g of alginic acid was dissolved in 100 mL of physiological saline to prepare a 20 g / L sodium alginate solution, wherein the molecular weight of alginic acid was 350 kDa.

[0036] 2) Preparation of galactosyl chitosan solution: Dissolve galactosyl chitosan in physiological saline to prepare galactosyl shells with concentrations of 0, 15g / L, 20g / L, 30g / L and pH 7.0 polysaccharide solution.

[0037] 3) Preparation of gel bath solution: 11 g of anhydrous calcium chloride was dissolved in 1 L of deionized water.

[0038] 4) Take 2mL of sodium alginate solution, mix 2mL of different concentrations of galactosyl chitosan solutions obtained in step 2) respectively, and stir at room temperature for 3h. At this time, the concentration of sodium alginate is 10g / L, and the concentration of galactosyl chitosan 0, 7.5g / L, 10g / L, 15g / L in turn, using the electrostatic droplet method to prepare calcium alginate / galactosyl chitosan embedd...

Embodiment 2

[0044] 1) Preparation of sodium alginate solution: 3.0 g of alginic acid was dissolved in 100 mL of physiological saline to prepare a 30 g / L sodium alginate solution, wherein the molecular weight of alginic acid was 350 kDa.

[0045] 2) Preparation of FITC-labeled galactosyl chitosan solution: FITC-labeled galactosyl chitosan was dissolved in physiological saline to prepare a galactosyl chitosan solution with a concentration of 10 g / L and a pH of 7.0.

[0046] 3) Preparation of gel bath solution: 11 g of anhydrous calcium chloride was dissolved in 1 L of deionized water.

[0047] 4) Take 2 mL of sodium alginate solution, mix 2 mL of the galactosyl chitosan solution obtained in step 2) respectively, and stir at room temperature for 3 h. At this time, the concentration of sodium alginate is 15 g / L, and the concentration of galactosyl chitosan is 5 g / L. L, Calcium alginate / galactosyl chitosan-embedded hydrogel microsphere carrier prepared by electrostatic droplet method.

Embodiment 3

[0049] 1) Preparation of sodium alginate solution: 2.0 g of alginic acid was dissolved in 100 mL of physiological saline to prepare a 20 g / L sodium alginate solution, wherein the molecular weight of alginic acid was 350 kDa, and it was sterilized by filtration.

[0050]2) Preparation of galactosyl chitosan solution: 0.4 g of galactosyl chitosan was dissolved in 10 mL of physiological saline to prepare a 40 g / L chitosan solution, adjusted to pH 7.2, and sterilized by filtration.

[0051] 3) Preparation of gel bath solution: 11 g of anhydrous calcium chloride was dissolved in 1 L of deionized water, and sterilized by filtration.

[0052] 4) Preparation of α-polylysine solution: α-polylysine was dissolved in physiological saline to prepare a 5 g / L α-polylysine solution, which was sterilized by filtration. Among them, the molecular weight of α-polylysine is 30kDa.

[0053] 5) Take 3 mL of sodium alginate solution, mix with 1 mL of galactosyl chitosan solution, and stir at room te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com