Method of preparing sugar solution

A manufacturing method and technology of sugar solution, applied in biochemical equipment and methods, glycosylase, biofuel, etc., can solve the problems of increased cost and high enzyme cost, and achieve the effect of suppressing manufacturing cost and improving the reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

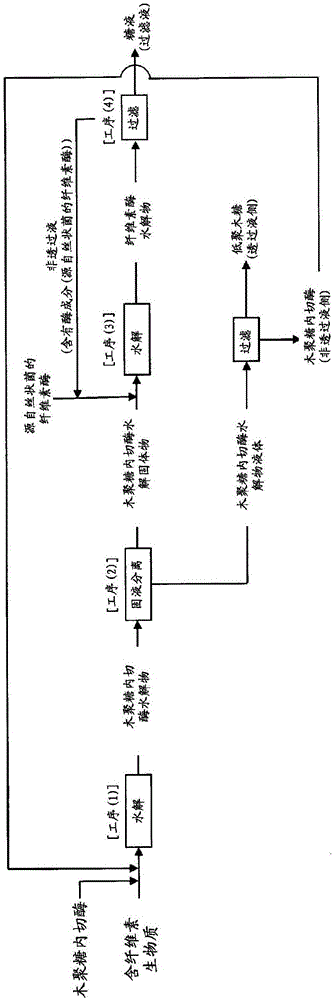

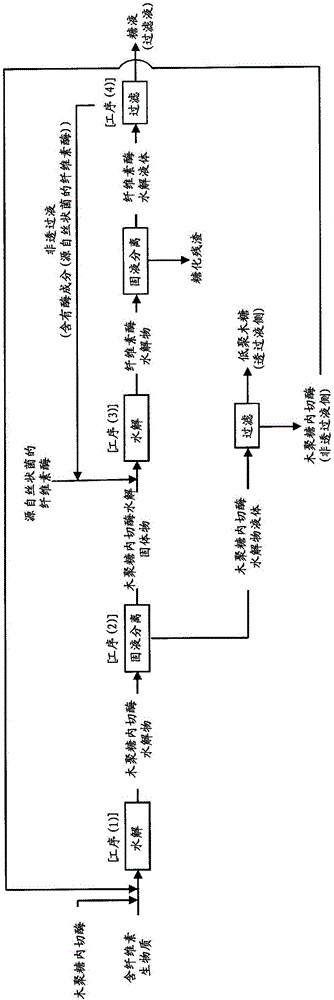

Method used

Image

Examples

Embodiment

[0092]Examples are given below to describe the present invention concretely. However, the present invention is not limited by these Examples.

reference example 1

[0093] (Reference Example 1) Preparation of cellulase (culture solution) derived from filamentous bacteria

[0094] Cellulase (culture solution) derived from filamentous fungi was prepared as follows.

[0095] [pre-culture]

[0096] Corn steeping liquid 25% (w / vol), glucose 2% (w / vol), ammonium tartrate 0.37% (w / vol), ammonium sulfate 0.14 (w / vol), calcium dihydrogen phosphate 0.2% (w / vol ), calcium chloride dihydrate 0.03% (w / vol), magnesium sulfate heptahydrate 0.03% (w / vol), zinc chloride 0.02% (w / vol), iron (Ⅲ) chloride hexahydrate 0.01 % (w / vol), copper sulfate (II) pentahydrate 0.004% (w / vol), manganese chloride tetrahydrate 0.0008% (w / vol), boric acid 0.0006% (w / vol), and heptamolybdic acid Add hexammonium tetrahydrate 0.0026% (w / vol) to distilled water, pour 100mL of distilled water containing the above components into a 500mL Erlenmeyer flask with baffles, and autoclave at 121°C for 15 minutes . After standing to cool, PE-M and Tween80 separately autoclaved at 121...

reference example 2

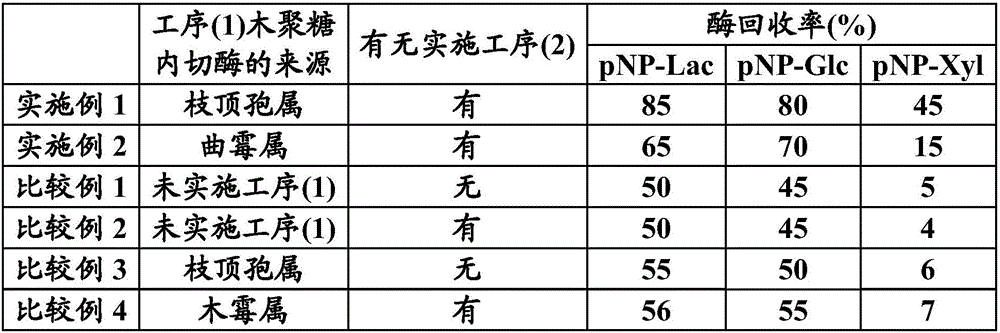

[0099] (Reference Example 2) Method for Measuring Activity of Cellulase Derived from Filamentous Fungi

[0100] The enzymatic activity of cellulase derived from filamentous fungi was measured and evaluated by the method shown below as the activity of the enzyme group involved in cellulolysis, as the activity of cellobiose and endoglucanase (1) 4 - Decomposition activity of nitrophenyl-β-D-lactopyranoside (pNP-Lac), measured and evaluated as β-glucosidase activity by the method shown below (2) 4-nitrophenyl-β- The decomposition activity of D-glucopyranoside (pNP-Glc), as the activity of endoxylanase and xylosidase involved in the decomposition of xylan, the main component of hemicellulose, was measured and evaluated by the method shown below ( 3) Decomposing activity of 4-nitrophenyl-β-D-xylopyranoside (pNP-Xyl). In addition, the substrates of the above (1) to (3) are collectively referred to as pNP-sugar.

[0101] 0.1 mL of enzyme solution was added to 0.9 mL of 100 mM aceta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com