Liquid crystal aligning agent, liquid crystal aligning film and liquid crystal display element

A liquid crystal alignment film and liquid crystal alignment technology, which is applied in instruments, optics, nonlinear optics, etc., can solve problems such as liquid crystal alignment film display defects, liquid crystal display element display defects, etc., and achieve excellent resistance, low surface roughness, and thermal stability. Effect of Deterioration Suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

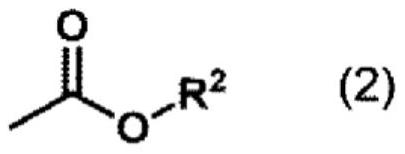

[0186] The preparation method of the liquid-crystal aligning agent of this invention is not specifically limited. For example, the following methods are mentioned: a method of mixing component (A) at a specific ratio in a solution of component (B) dissolved in a solvent to prepare a homogeneous solution; or, in an appropriate stage of the production method, as needed A method of further adding and mixing the above-mentioned crosslinkable compound, a compound for improving the film thickness uniformity and surface smoothness of the resin film or liquid crystal aligning film, a compound for accelerating decharge, a dielectric substance, and a conductive substance.

[0187] In preparation of the liquid-crystal aligning agent of this invention, the solution of the polymer which is (B) component obtained by the polymerization reaction in a solvent can be used as it is. In this case, for example, (A) component etc. are injected|thrown-in to the solution of (B) component similarly to...

Embodiment

[0206] Hereinafter, although an Example is given and this invention is demonstrated in more detail, it is not limited to these.

[0207] It should be noted, 1 The measurement apparatus and measurement conditions of H-NMR are as follows.

[0208] Device: Fourier transform superconducting nuclear magnetic resonance device (FT-NMR) INOVA-400 (manufactured by Varian Corporation) 400MHz

[0209] Solvent: deuterated chloroform (CDCl 3 )

[0210] Standard substance: Tetramethylsilane (TMS)

[0211] Cumulative times: 8

Synthetic example 1X-1

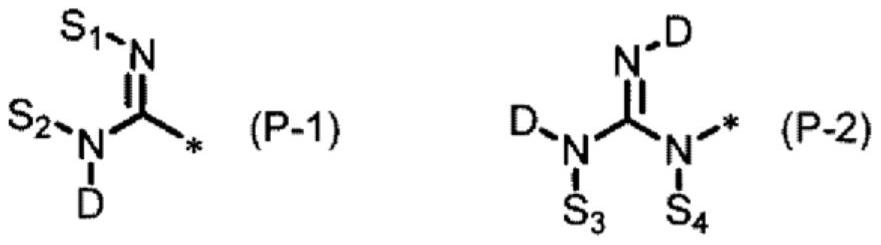

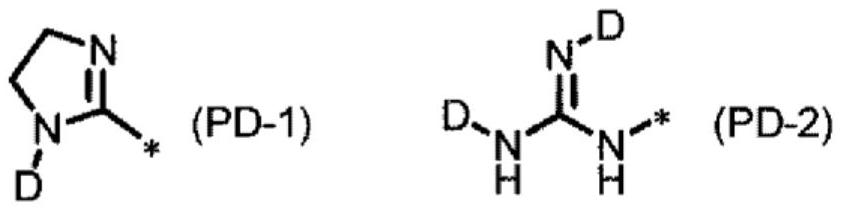

[0212] [Synthesis Example 1] Synthesis of X-1

[0213]

[0214] Put 73.2 g of dichloromethane, 4.00 g (13.8 mmol) of N,N'-bis(tert-butoxycarbonyl)-S-methylisothiourea, and 1.77 g of benzylamine into a 200 mL four-neck flask equipped with a magnetic stirrer (1.2eq) and triethylamine (Et 3 N) 2.83g (2.0eq), after nitrogen substitution, N-iodosuccinimide (NIS) 3.10g (1.0eq) was added, and it stirred at room temperature. After 3 hours, add benzylamine 2.22g (1.5eq), N-iodosuccinimide (NIS) 1.54g (1.0eq) and triethylamine (Et 3 N) 1.39g (1.0eq), further reacted for 40 hours. After the reaction, the dichloromethane layer was washed twice with 1.0M aqueous sodium thiosulfate (50 ml) and twice with 0.5M aqueous hydrochloric acid (50 ml). Thereafter, water washing was performed twice with pure water (100 ml), and the dichloromethane layer was recovered. Yellow crystals were recovered by concentrating the recovered dichloromethane layer under reduced pressure, and dissolved in 28...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com