Welding system for aluminum material machining

A welding system and aluminum material technology, applied in welding equipment, metal processing equipment, welding/welding/cutting items, etc., can solve the problems of large power consumption, easy oxidation, burn-through and collapse, etc., to improve utilization efficiency, Improve welding strength and reduce oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

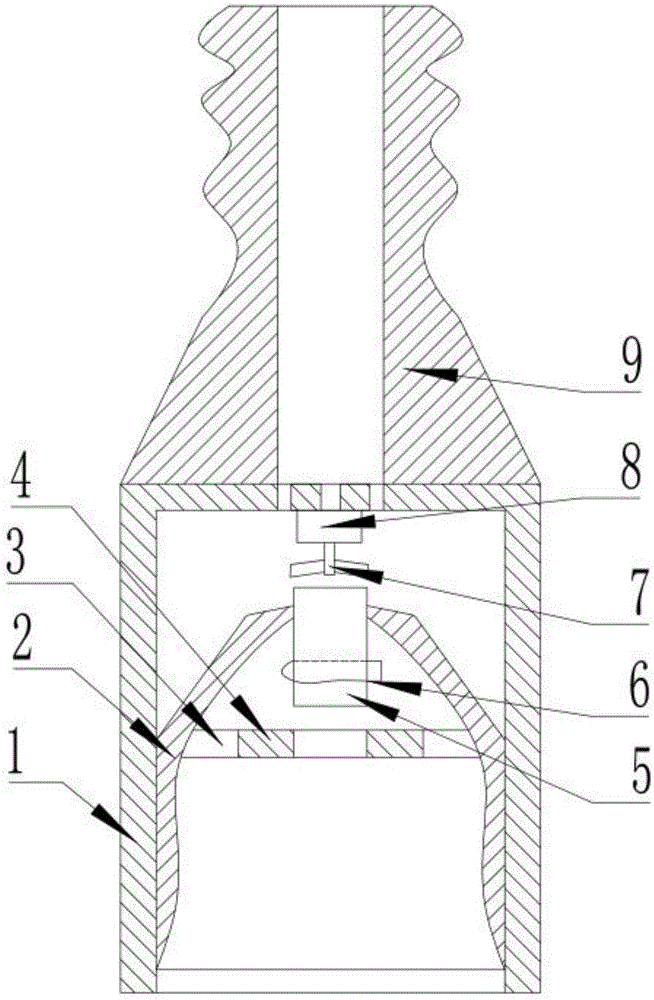

[0023] Such as figure 2 As shown, a welding system for processing aluminum materials, the welding system is mainly composed of a welding device and a power supply device; 5. The fixed coil 6 and the handle 9 are composed; the shell 1 is cylindrical with one end open, and the sealing end of the shell 1 is connected to the handle 9; the sound wave lens 2 is bell-shaped, and the sound wave lens 2 is arranged inside the shell 1, and the sound wave lens 2 The opening direction of the housing 1 is the same as the opening direction of the housing 1; the vibrating membrane 3 is in the shape of a circular sheet, the vibrating membrane 3 is arranged inside the acoustic wave lens 2, and the moving coil 4 is connected with the vibrating membrane 3; the magnetic core 5 is arranged at the bottom of the acoustic wave lens 2 The fixed coil 6 is arranged on the outer periphery of the magnetic core 5; the axes of the fixed coil 6, the magnetic core 5, the vibrating membrane 3 and the moving co...

Embodiment 2

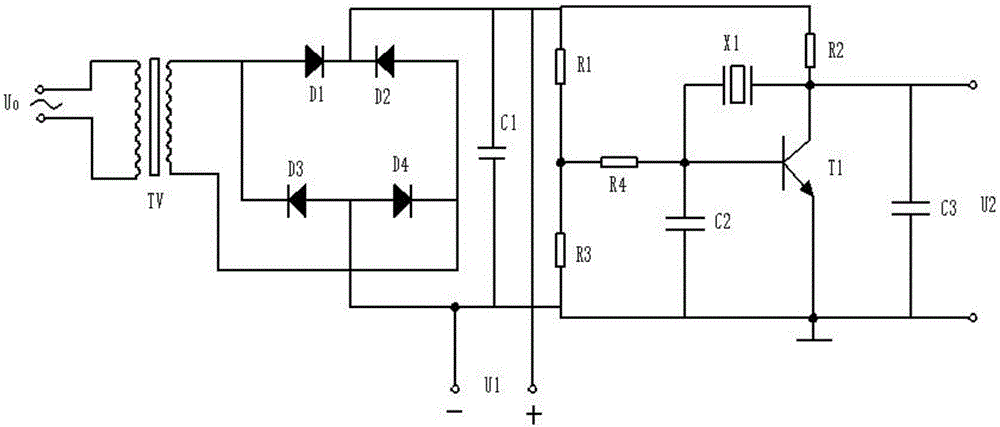

[0026] Such as figure 1 with figure 2 As shown, a welding system for processing aluminum materials, the welding system is mainly composed of a welding device and a power supply device; the power supply device is mainly composed of a step-down rectifier circuit, a first output circuit and a second output circuit; the In the step-down rectifier circuit, the input stage of the transformer TV is connected to the power supply, and the output stage of the transformer TV is connected to the input end of the full-bridge rectifier circuit composed of diode D1, diode D2, diode D3, and diode D4; the first output circuit The middle capacitor C1 is connected in parallel with the output terminal of the full-bridge rectifier circuit, and the two poles drawn out of the capacitor C1 are the output terminal U1 of the first output circuit; the resistor R1 and the resistor R3 in the second output circuit are connected in parallel with the capacitor C1 after being connected in series; the capacit...

Embodiment 3

[0031] On the basis of Embodiment 1 and Embodiment 2, this embodiment discloses a preferred structure of a welding system for aluminum material processing, such as figure 1 with figure 2 As shown, each point on the inner wall of the acoustic wave lens 2 is symmetrical to the vertical line connecting each point of the vibrating membrane 3 and the preset processing point with respect to this point; the material of the acoustic wave lens 2 is quartz. The acoustic wave lens 2 converges the ultrasonic waves emitted by the vibrating membrane 3, which greatly increases the energy density of the working surface; the high hardness of quartz can reflect high-frequency sound waves, and the absorption rate is low, which improves the conversion efficiency of the equipment.

[0032] Further, the number of turns of the moving coil 4 is one, the material of the moving coil 4 is silver, the number of turns of the fixed coil 6 is one, and the material of the fixed coil 6 is copper. A one-turn c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com