Deep denitrogenation treatment method for wastewater produced during coal water slurry gasification process

A technology of deep denitrification and treatment method, applied in water/sewage multi-stage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. Effects of nitrification and denitrification, inhibition of activity, and reduction of dissolved oxygen consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

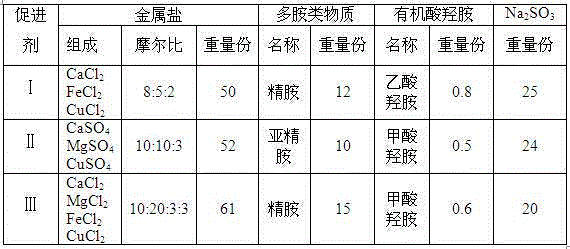

[0024] The preparation of embodiment 1 microbial growth promoter

[0025] The microbial growth promoter used in the present invention is prepared according to the methods described in CN201410585483.6, CN201410585481.7 and CN201410585655.X, preferably by the method described in CN201410585655.X. First prepare the metal salt solution according to the ratio and formula of the microbial growth promoter in Table 1. Before use, polyamines, organic acid hydroxylamine and Na 2 SO 3 Added into the metal salt solution to prepare microorganism growth promoters I-III, the concentrations of the promoters are all 0.5g / L.

[0026] Table 1 The formula and ratio of microbial growth promoter

[0027]

Embodiment 2

[0028] The preparation of embodiment 2 denitrification bacteria agent

[0029] The denitrification bacteria agent used in the method of the present invention comprises five bacterial strains of Coxella palustris FSDN-A, Arthrobacter FDN-1, Flavobacterium waterii FDN-2, Paracoccus denitrificans DN-3 and Methylobacterium SDN-3 , the microbial bacterial agent used is prepared according to the method described in Example 1 of CN201210130645.8, and finally obtained the bacterial suspension A (the volume ratio of five bacterial strains is 1:1:1:1:1) harvested according to different proportions ) and bacterial suspension B (the volume ratio of the five strains is 1:1:2:1.5:3).

Embodiment 3

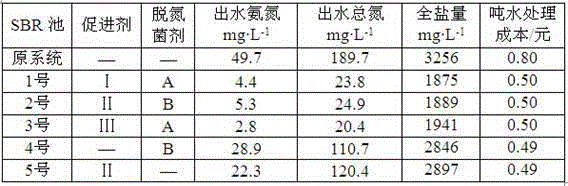

[0030] The treatment result of embodiment 3 waste water

[0031] The waste water generated during the hydrogen production process of Texaco coal-water slurry gasification technology in an enterprise is treated by the process of five sets of SBR alternate operation. The ammonia nitrogen concentration in the influent water is 300mg / L, the COD is 450mg / L, and the total salt content is 2000-2800mg / L. After the original SBR process, the ammonia nitrogen concentration in the effluent water is about 50mg / L, the COD is less than 50mg / L, The nitrogen concentration is about 200mg / L, and the total salt content is about 3200mg / L. On the one hand, the effluent ammonia nitrogen cannot meet the standard, on the other hand, the salt content is high, and the treatment cost per ton of water is 0.8 yuan.

[0032] The specific process is as follows: (1) A dissolved air flotation system is added at the front end of the SBR process, and the working pressure of the dissolved air flotation is control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com