Glass ceramic with abrasion resistance prepared by adopting industrial wastes

A technology of industrial waste and glass-ceramics, which is applied in the field of wear-resistant glass-ceramics, can solve the problems of occupying land resources, polluting the environment, and threatening people's health, and achieves low surface porosity, good acid and alkali resistance, and wear-resistant The effect of superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

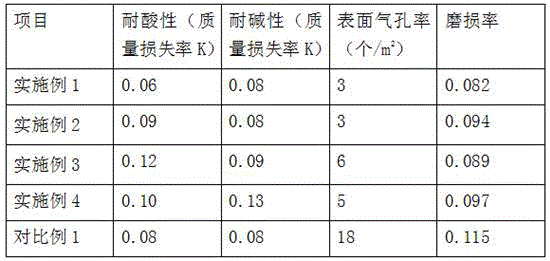

Examples

Embodiment 1

[0021] Example 1: A wear-resistant glass-ceramic prepared from industrial waste, including the following components in parts by weight: 56 parts of silicon dioxide, 14 parts of tantalum-niobium tailings, 12 parts of calcium oxide, 14 parts of magnesium oxide, 2 parts of sodium, 0.2 parts of boron oxide, 0.09 parts of copper sulfate, 0.4 parts of nickel sulfide, 0.08 parts of magnesium diboride, 0.6 parts of clarifying agent, 2 parts of chromium trioxide;

[0022] The clarifying agent is composed of arsenic oxide and sodium nitrate in a mass ratio of 1:1.

[0023] A wear-resistant glass-ceramic prepared from industrial waste, the preparation method of which comprises the following steps:

[0024] Step 1: Mix the raw materials evenly, raise the temperature to 340°C, keep the temperature for 30 minutes, continue to raise the temperature to 1450°C, keep the temperature for 2 hours, and prepare the molten glass;

[0025] Step 2: After clarification and cooling to 1180°C, the molte...

Embodiment 2

[0029] Example 2: A wear-resistant glass-ceramic prepared from industrial waste, including the following components in parts by weight: 50 parts of silicon dioxide, 12 parts of tantalum-niobium tailings, 10 parts of calcium oxide, 10 parts of magnesium oxide, 1 part of sodium, 0.1 part of boron oxide, 0.05 part of copper sulfate, 0.2 part of nickel sulfide, 0.05 part of magnesium diboride, 0.5 part of clarifying agent, 1 part of chromium trioxide;

[0030] The clarifying agent is composed of arsenic oxide and sodium nitrate in a mass ratio of 1:1.

[0031] A wear-resistant glass-ceramic prepared from industrial waste, the preparation method of which comprises the following steps:

[0032] Step 1: Mix the raw materials evenly, raise the temperature to 350°C, keep the temperature for 20 minutes, continue to raise the temperature to 1480°C, keep the temperature for 3 hours, and prepare the molten glass;

[0033] Step 2: The molten glass is clarified and cooled to 1150°C and sent...

Embodiment 3

[0037] Example 3: A wear-resistant glass-ceramic prepared from industrial waste, comprising the following components in parts by weight: 60 parts of silicon dioxide, 15 parts of tantalum-niobium tailings, 15 parts of calcium oxide, 15 parts of magnesium oxide, 3 parts of sodium, 0.3 parts of boron oxide, 0.1 part of copper sulfate, 0.5 parts of nickel sulfide, 0.12 parts of magnesium diboride, 0.8 parts of clarifying agent, 3 parts of chromium trioxide;

[0038] The clarifying agent is composed of arsenic oxide and sodium nitrate in a mass ratio of 1:1.

[0039] A wear-resistant glass-ceramic prepared from industrial waste, the preparation method of which comprises the following steps:

[0040] Step 1: Mix the raw materials evenly, raise the temperature to 300°C, keep the temperature for 40 minutes, continue to raise the temperature to 1400°C, keep the temperature for 1 hour, and prepare the glass liquid;

[0041] Step 2: The molten glass is clarified and cooled to 1200°C and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com