Dielectric material for multilayer ceramic capacitor with medium-high voltage X7R characteristics

A technology of dielectric materials and multilayer ceramics, which is applied in the direction of fixed capacitor dielectrics, laminated capacitors, capacitors, etc., can solve the problems of low dielectric constant, difficulty in miniaturization, large capacity, and inability to improve withstand voltage and reliability, etc. problem, achieve high insulation resistance, good temperature stability and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The preparation process of dielectric material in the embodiment is:

[0050] First, the main component barium yttrium titanate (Ba 1-a Y a ) b TiO 3 ; Next, mixing auxiliary additive components and calcining at 500-800°C; then calcined powder, MgTiO 3 Added to (Ba 1-a Y a ) b TiO 3 , mixed together, dispersed, and dried to obtain MLCC dielectric materials.

[0051] Then the above-mentioned obtained dielectric material is made into a slurry, and the slurry is made into a dielectric green diaphragm through a casting machine, and nickel or nickel alloy electrodes are printed on the surface of the diaphragm by a screen printing machine, and then the diaphragm is laminated according to the number of layers designed and printing internal electrodes; alternately stack and print the dielectric films of the internal electrodes to form a laminate; then undergo isostatic pressing and cutting to form a green body, and sinter the green body in a reducing atmosphere at 1260-...

Embodiment 1

[0053] First, the solid-phase method was used to prepare (Ba 1-a Y a ) b TiO 3 powder (see figure 1 ); Next, the MnCO 3 , SiO 2 、Ho 2 o 3 , V 2 o 5 powders (with a particle size below 0.3 microns) were mixed, and calcined at 650°C for 2 hours to obtain powders with an average particle size of 0.2-0.3 microns; then, the calcined powder, MgTiO 3 Added to (Ba 1-a Y a ) b TiO 3 , mixed together, dispersed, and dried to obtain MLCC dielectric materials.

Embodiment 2-30

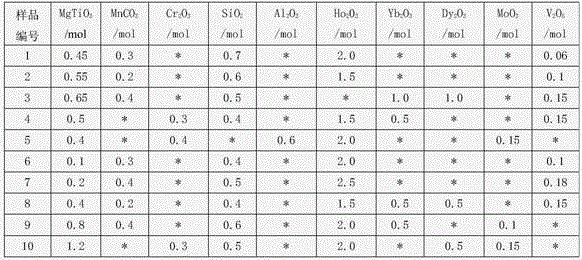

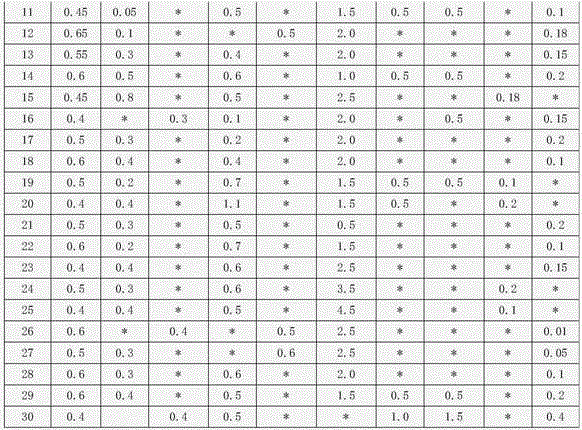

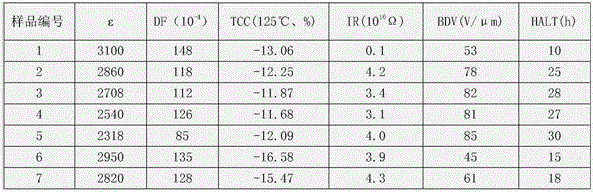

[0055] The preparation process is the same as in Example 1, except that the addition amount of each component is different. The addition amount of each composition is as shown in table 1, and in each embodiment, as shown in the table, the medium material (the embodiment number is the sample number) that preparation addition amount is different, in table 1, the addition amount of each composition is relative to 100 Moore (Ba 1-a Y a ) b TiO 3 converted. Among the materials, (Ba1-aYa)bTiO with a=0.02 and b=1.02 is used 3 .

[0056] Table 1: Specific components and proportions of dielectric materials

[0057]

[0058]

[0059] Note, * means the addition amount is 0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com