SiC-based composite ceramic and preparation method thereof

A technology for multiphase ceramics and ceramic powder, which is applied in the field of SiC-based multiphase ceramics and its preparation, can solve the problems of inability to meet the injection molding process, increase the concentration of free radicals, and form ceramic components of silicon carbide structure, and achieve excellent polishability. , Low thermal expansion coefficient, no effect of sintering shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

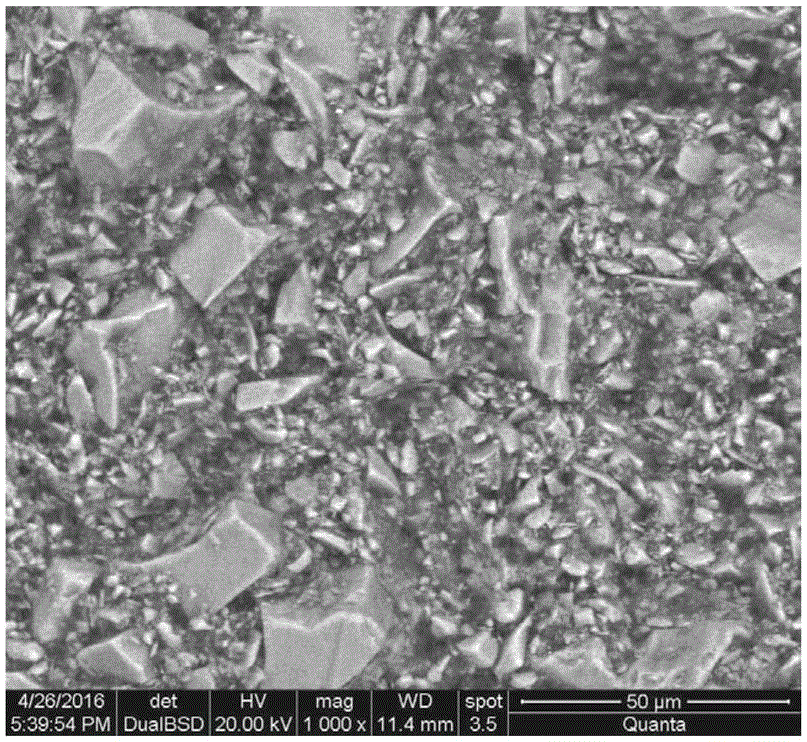

[0033] A SiC-based composite phase ceramics of the present invention, specifically Si / SiC composite phase ceramics, including Si and SiC, wherein SiC is a continuous matrix phase, Si is a free phase, and the free phases are distributed on the surface of the SiC-based composite phase ceramics in the continuous matrix phase.

[0034] The Si / SiC composite ceramics is made of a mixed slurry sintered by gas-phase silicon infiltration. The mixed slurry is specifically composed of carbon black, α-SiC ceramic powder, acrylamide (organic monomer), N,N'-methylene bis Acrylamide (crosslinking agent), AIBA (initiator) and deionized water. After the mixed slurry is sintered by gas phase siliconization, carbon black is sintered by gas phase siliconization to generate β-SiC. β-SiC and the mixed slurry α-SiC is sintered to form a continuous SiC phase, and the gas phase silicon that has not participated in the reaction condenses in SiC on the surface of SiC-based multiphase ceramics to form a ...

Embodiment 2

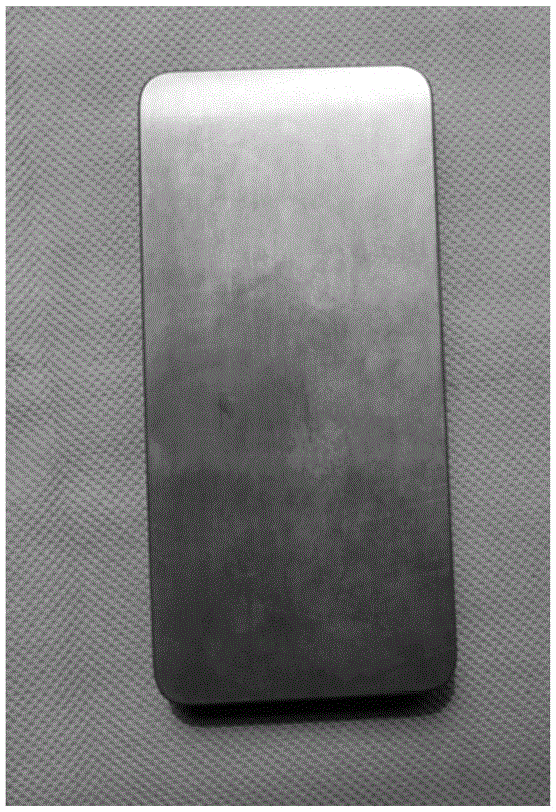

[0046] A SiC-based composite phase ceramics of the present invention, specifically Si / SiC composite phase ceramics, including Si and SiC, wherein SiC is a continuous matrix phase, Si is a free phase, and the free phases are distributed on the surface of the SiC-based composite phase ceramics in the continuous matrix phase.

[0047] The Si / SiC composite ceramics is made of a mixed slurry sintered by gas-phase silicon infiltration. The mixed slurry is specifically composed of carbon black, α-SiC ceramic powder, acrylamide (organic monomer), N,N'-methylene bis Acrylamide (crosslinking agent), AIBA (initiator) and deionized water. After the mixed slurry is sintered by gas phase siliconization, carbon black is sintered by gas phase siliconization to generate β-SiC. β-SiC and the mixed slurry α-SiC is sintered to form a continuous SiC phase, and the gas phase silicon that has not participated in the reaction condenses in SiC on the surface of SiC-based multiphase ceramics to form a ...

Embodiment 3

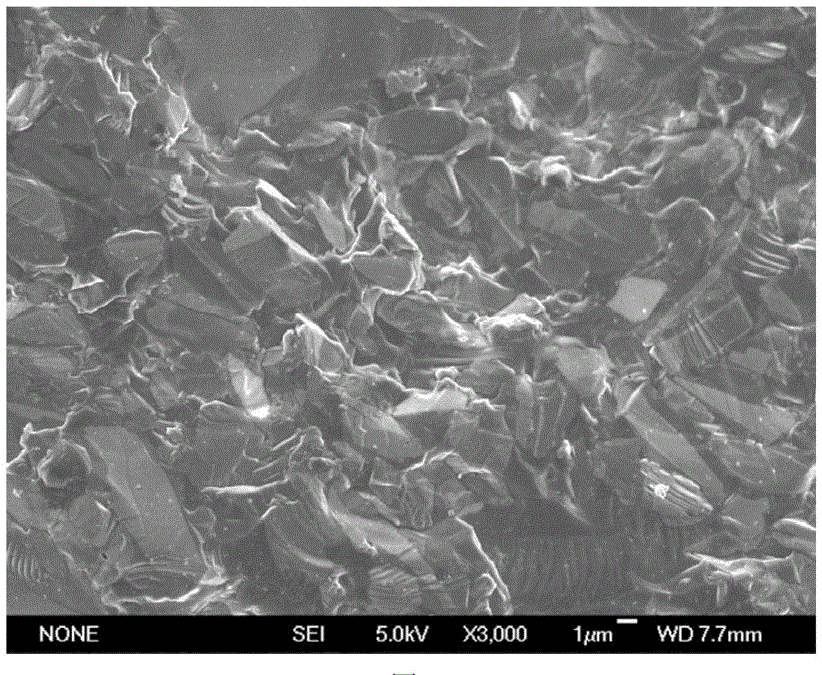

[0055] A SiC-based composite phase ceramics of the present invention, specifically Si / SiC composite phase ceramics, including Si and SiC, wherein SiC is a continuous matrix phase, Si is a free phase, and the free phases are distributed on the surface of the SiC-based composite phase ceramics in the continuous matrix phase.

[0056] The Si / SiC composite ceramics is made of a mixed slurry sintered by gas-phase silicon infiltration. The mixed slurry is specifically composed of carbon black, α-SiC ceramic powder, acrylamide (organic monomer), N,N'-methylene bis Acrylamide (crosslinking agent), AIBA (initiator) and deionized water. After the mixed slurry is sintered by gas phase siliconization, carbon black is sintered by gas phase siliconization to generate β-SiC. β-SiC and the mixed slurry α-SiC is sintered to form a continuous SiC phase, and the gas phase silicon that has not participated in the reaction condenses in SiC on the surface of SiC-based multiphase ceramics to form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com