Method for extracting usnic acid from cladonia alpestris

A technology of Taibaihua and usnic acid, which is applied in the field of natural medicinal chemistry, can solve the problems of unfavorable production scale, lengthy process, and insoluble usnic acid, so as to avoid cross-mixing problems, simple preparation process, and few types of solvents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The extraction and separation of usnic acid in Taibai flower of embodiment 1

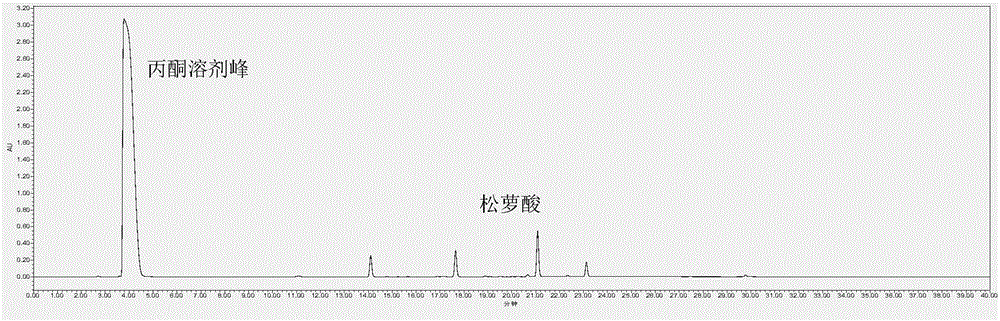

[0027] (1) Reflux extraction: crush the sun-dried Taibaihua into powder, weigh 100g, add ethyl acetate, and reflux extraction at 77°C for 3.5h; repeat the extraction 3 times in total, add 600mL ethyl acetate each time, and combine the filtrates 3 times , concentrated to get dry extract 4.8205g (see image 3 ).

[0028](2) Recrystallization: heat the dry extract with 44mL ethyl acetate (70-80°C) to dissolve, cool to 25°C and quickly ( Figure 4 ), the yield is 88.0%.

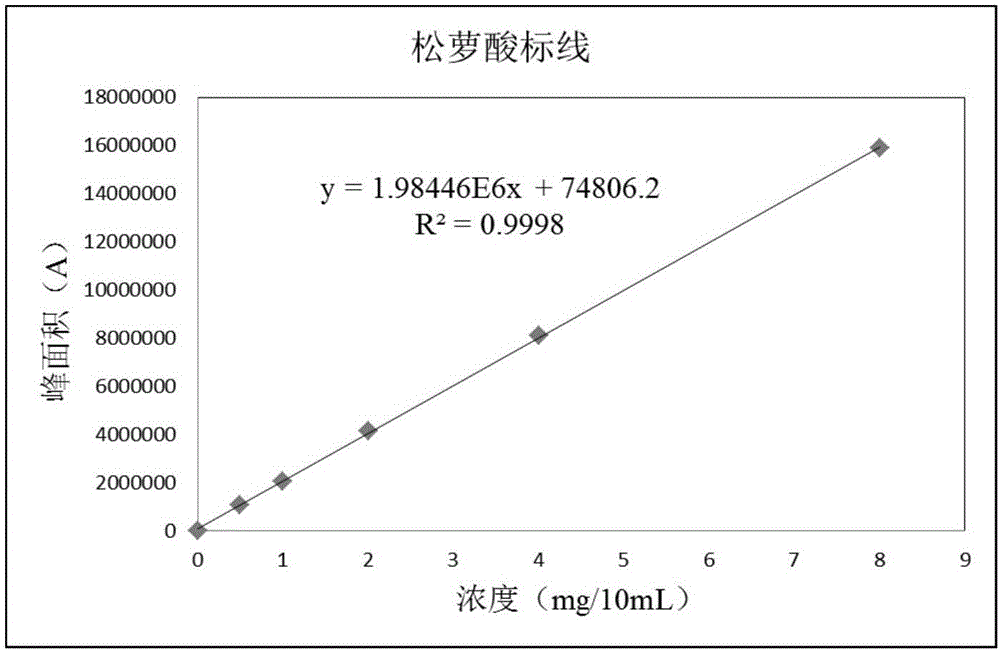

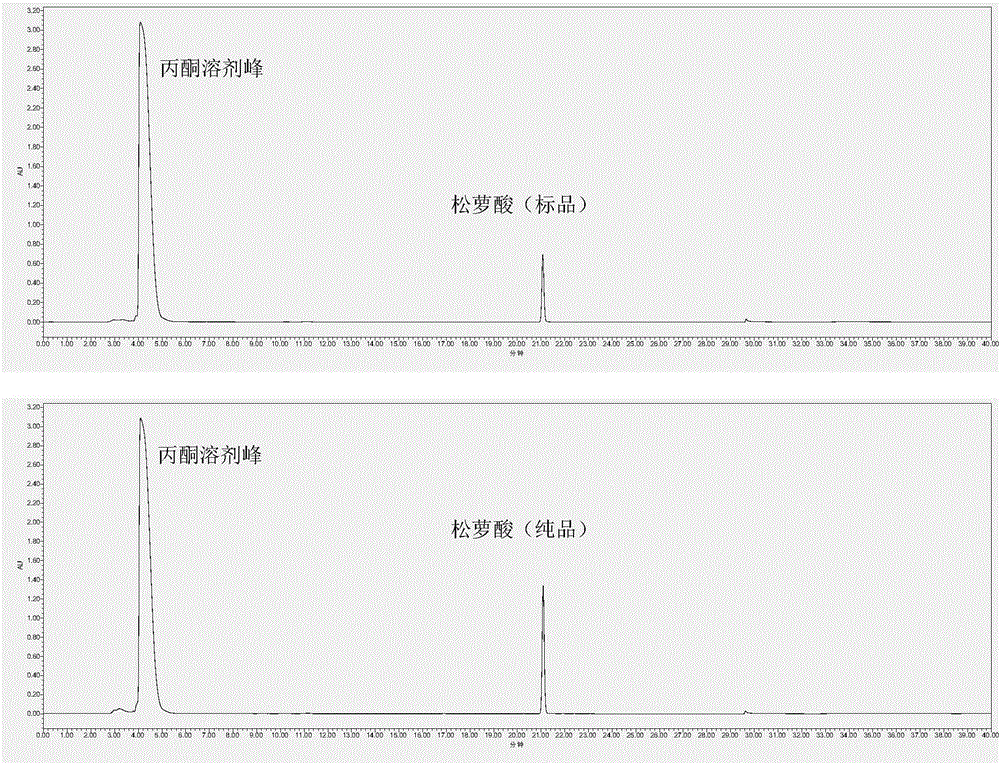

[0029] (3) Make the usnic acid standard curve: Accurately weigh 5 parts of usnic acid standard products, the masses are respectively 0.5mg, 1mg, 2mg, 4mg, 8mg, add 10mL acetone to fully dissolve respectively in these 5 parts of standard products, obtain the concentration 0.5mg / 10mL, 1mg / 10mL, 2mg / 10mL, 4mg / 10mL, the usnic acid standard solution of 8mg / 10mL, use high-performance liquid chromatography to measure the peak area of ...

Embodiment 2

[0033] Embodiment 2: Extraction and separation of usnic acid in Taibai Flos

[0034] (1) Reflux extraction: crush the sun-dried Taibaihua into powder, weigh 10kg, add ethyl acetate, reflux extraction at 77°C for 3.5h; repeat the extraction 3 times, add 40L ethyl acetate each time, and combine the filtrates 3 times , concentrated to give 481.6g dry extract.

[0035] (2) Recrystallization: heat the dry extract with 4L ethyl acetate (70-80°C) to dissolve, cool to 25°C and quickly ( Figure 5 ), the yield is 87.2%, and the purity is 98.15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com