Nanocellulose whisker modified bifunctional photoinitiator and preparation method thereof

A nanocellulose and photoinitiator technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of reducing the internal stress of the coating, low volatility, and inability to fully exert cellulose properties, and achieve enhanced mechanical The effect of good performance, tensile resistance and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

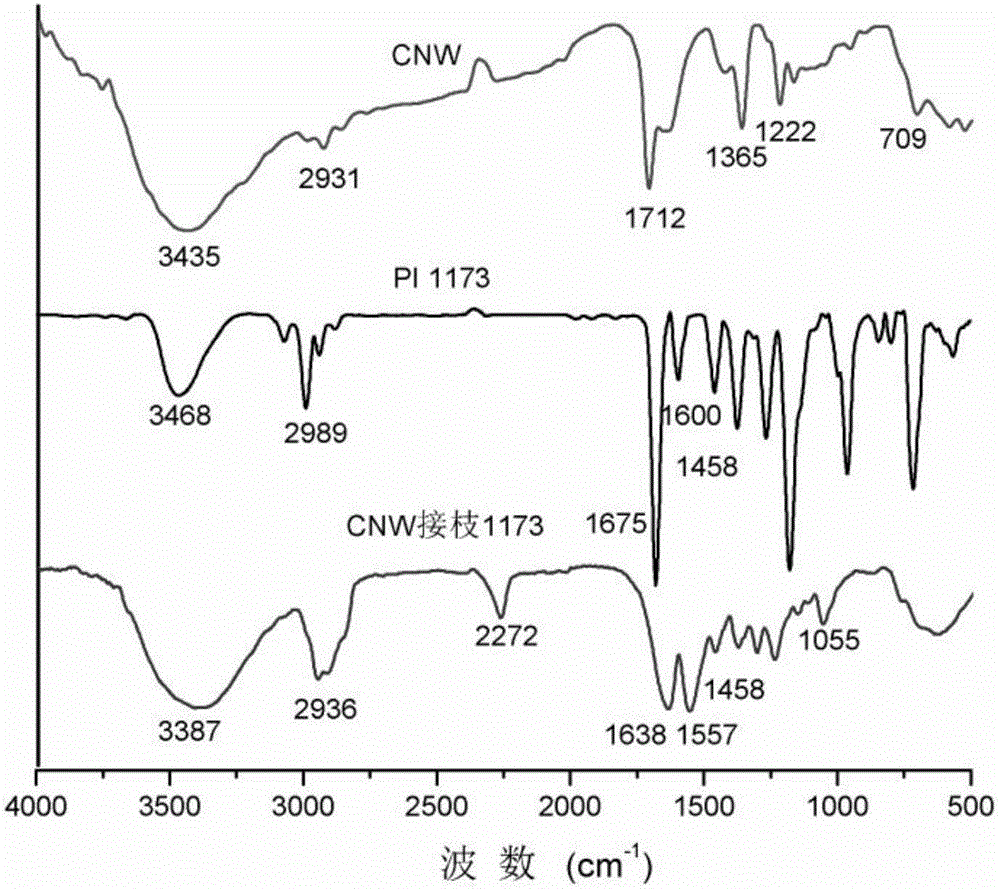

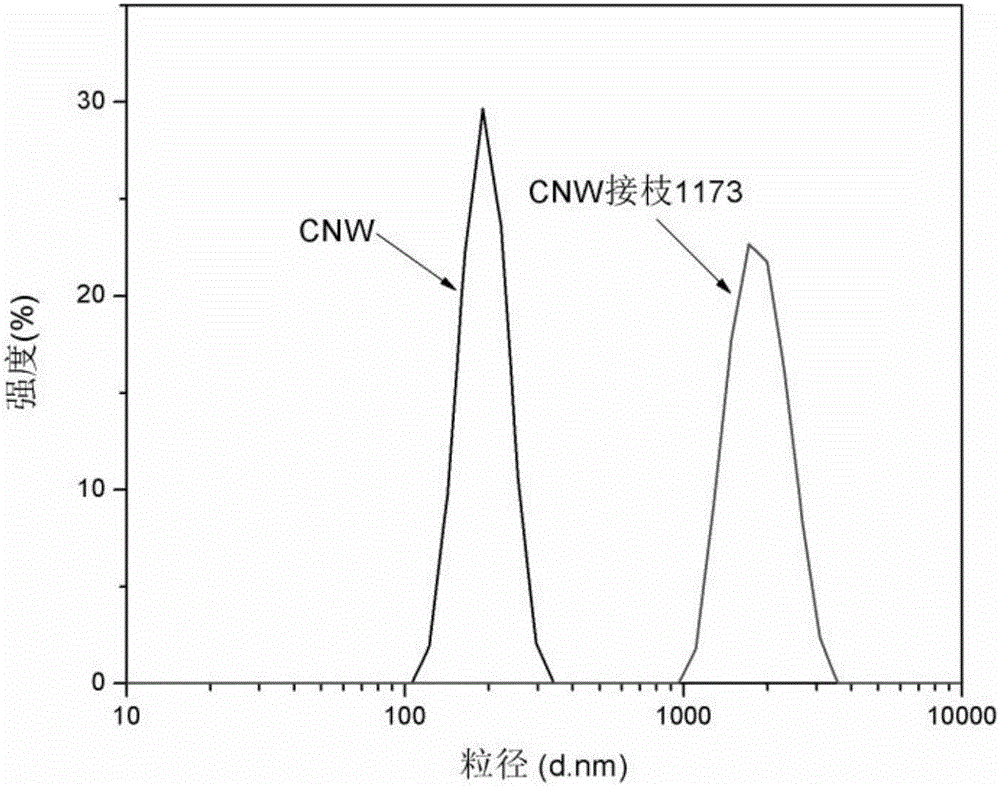

[0047] The preparation method of water-dispersed nano-cellulose whiskers: use absorbent cotton as raw material, add sulfuric acid with a mass concentration of 64%, hydrolyze in a water bath at 60°C for 3 hours, add an appropriate amount of deionized water to terminate the reaction, cool down to room temperature, add NaOH / Na 2 CO 3 Buffer solution, neutralized to a pH value of 7, centrifuged to filter the neutralized solution, washed several times with deionized water, then ultrasonically dispersed on an ultrasonic instrument, placed in a dialysis bag for dialysis for about 10 days, and obtained a solid mass content of 1.4% suspension.

[0048] The preparation method of acetone-dispersed nanocellulose whiskers: vacuum freeze-drying water-dispersed nanocellulose whiskers at a vacuum degree of 100 Pa and a temperature of -45°C for 48 hours to obtain dry and fluffy nanocellulose whiskers solids, and then Add acetone and ultrasonically disperse for 30 minutes to obtain acetone-dis...

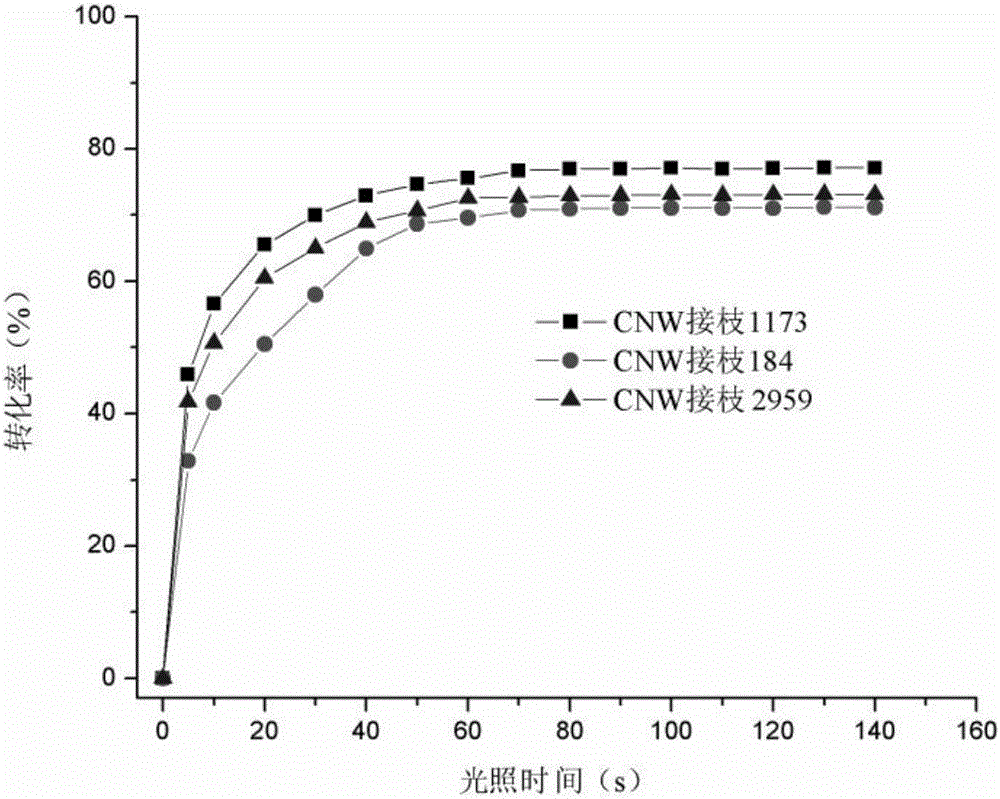

Embodiment 1

[0053] In this embodiment, the diisocyanate is selected from isophorone diisocyanate (IPDI), the photoinitiator is selected from Darocur1173, the catalyst is dibutyltin dilaurate, the mass ratio of nanocellulose whiskers to IPDI is 1:5, and the molar ratio of IPDI to Darocur1173 The ratio is 1:1.5.

[0054] Synthesis of nanocellulose whiskers and diisocyanate semi-adducts: 9.49g IPDI and 1.89g freeze-dried nanocellulose whiskers (sonically dispersed with 25g acetone) were added to a four-neck tube with stirring, pumping and cooling tubes In the flask, 0.0572g of catalyst was added dropwise, followed by nitrogen gas for 10 minutes to remove the oxygen in the reaction environment. Stirring and reacting at 60-65°C for 3 hours to obtain nanocellulose whiskers-IPDI semi-adduct.

[0055] Modification of the photoinitiator: 10.51 g of Darocur 1173 was dropped into a four-necked flask and allowed to react with another NCO group of the diisocyanate for 4 hours. The reaction product w...

Embodiment 2

[0059] In the present embodiment, diisocyanate selects isophorone diisocyanate (IPDI) for use, photoinitiator selects Irgacure 184 for use, catalyzer is dibutyltin dilaurate, the mass ratio of nanocellulose whisker and IPDI is 1:5, IPDI and Irgacure 184 molar ratio is 1:1.5.

[0060] Synthesis of nanocellulose whiskers and diisocyanate semi-adducts: 9.49g IPDI and 1.89g freeze-dried nanocellulose whiskers (sonically dispersed with 25g acetone) were added to a four-neck flask with stirring, air extraction and condenser tubes In, 0.0572g catalyst was added dropwise, and nitrogen gas was passed for 10 minutes to remove oxygen in the reaction environment. Stirring and reacting at 60-65°C for 3.5 hours to obtain nanocellulose whiskers-IPDI semi-adduct.

[0061] Modification of the photoinitiator: 13.07g of Irgacure 184 was dropped into a four-necked flask to react with another -NCO group of IPDI for 4.5 hours. The reaction product was centrifuged to remove the supernatant; it was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com