a biodegradable adhesive

A biodegradable, adhesive technology, applied in the direction of adhesives, adhesive additives, aldehyde/ketone condensation polymer adhesives, etc., can solve the problems of poor permeability, low survival rate, easily broken and damaged roots, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

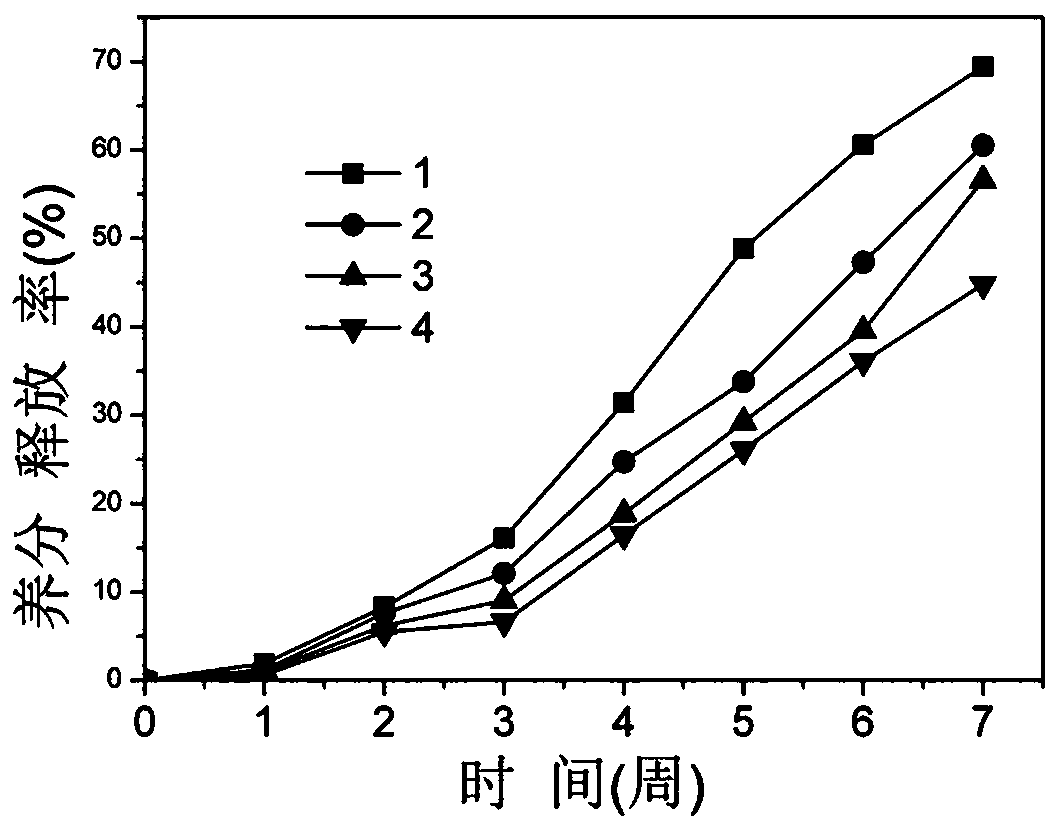

Image

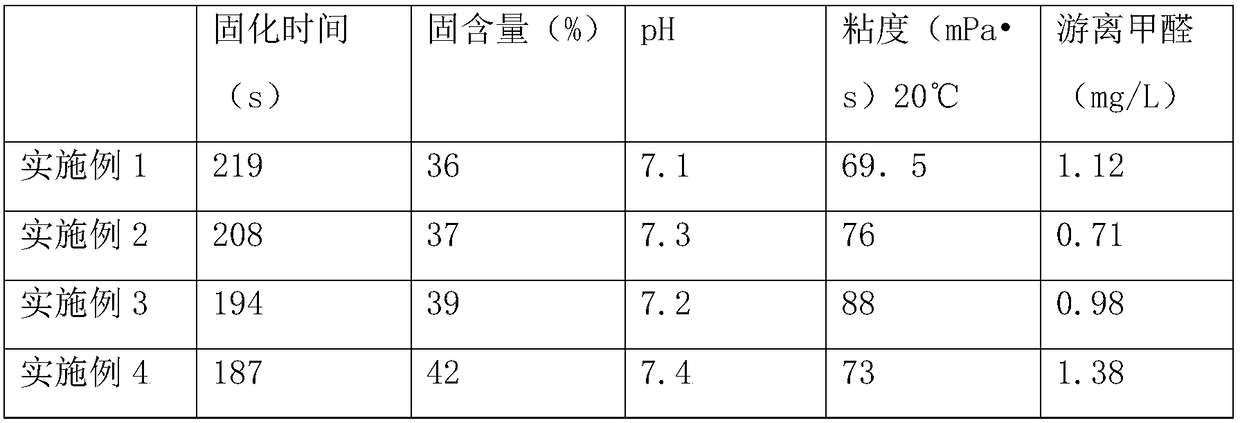

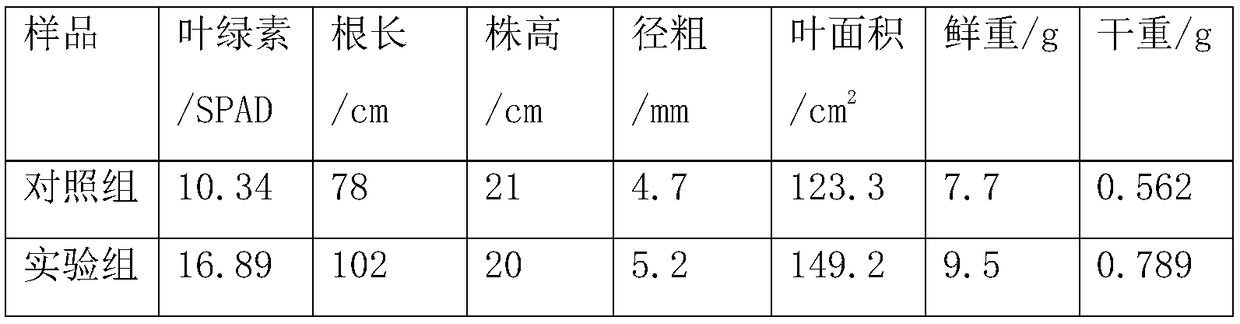

Examples

Embodiment 1

[0030] The preparation of embodiment 1 biodegradable adhesive

[0031] 1. Preparation of hydrolyzed protein:

[0032] The protein used in the examples is zein, and the manufacturer is Shandong Shouguang Juneng Golden Corn Development Co., Ltd.

[0033] Prepare a mixed aqueous solution of potassium hydroxide with a final concentration of 1mol / L urea and 0.01mol / L, heat it to 95°C, add zein to it, heat and stir for 1 hour, then naturally cool and discharge the material to obtain a hydrolyzed solution with a solid content of 15%. protein.

[0034] 2. Preparation of hydrolyzed protein-urea-formaldehyde copolymer:

[0035] Add formaldehyde into the reaction kettle, adjust the pH to 7.2 with an alkaline solution (20% potassium hydroxide solution) (during the specific operation, the pH range can be selected between 7.0-7.5); add the first Urea (the quality is 70% of the total amount of urea added) and hydrolyzed protein, stop heating when the temperature is raised to 50 ° C, when ...

Embodiment 2

[0040] The preparation of embodiment 2 biodegradable adhesives

[0041](a) Preparation of hydrolyzed protein: Prepare a mixed aqueous solution with a final concentration of 2mol / L urea and 0.01mol / L potassium hydroxide, heat to 90°C, add soybean protein isolate, stir for 1 hour, then naturally cool and discharge to obtain a solid content 12% hydrolyzed protein.

[0042] (b) Preparation of hydrolyzed protein-urea-formaldehyde copolymer: formaldehyde is added in the reactor, with alkaline solution (mass fraction is the dipotassium hydrogen phosphate of 20% and the mass fraction is the potassium hydroxide equivolume mixed solution of 20%) ) to adjust the pH to 7.0; add urea for the first time (the quality is 75% of the total mass of urea) and the hydrolyzed protein obtained in step (a), stop heating after the temperature is raised to 50 ° C, and when the temperature no longer continues to rise, then Heat up to 90°C and keep warm at this temperature for half an hour;

[0043] Us...

Embodiment 3

[0045] The preparation of embodiment 3 biodegradable adhesives

[0046] (a) Preparation of hydrolyzed protein: Prepare a mixed aqueous solution with a final concentration of 2mol / L urea and 0.02mol / L potassium hydroxide, heat to 90°C, add a mixture of soybean protein isolate and corn protein (mass ratio 1:1) , stirred for 1 h, then cooled and discharged to obtain hydrolyzed protein with a solid content of 15%.

[0047] (b) Preparation of hydrolyzed protein-urea-formaldehyde copolymer: formaldehyde is added in the reactor, adjust pH=7.0 with alkaline solution (mass fraction is the potassium hydroxide solution of 25%); Add urea for the first time (being urea 75% of the total mass) and the hydrolyzed protein obtained in step (a), the temperature is raised to 50°C to stop heating, and when the temperature does not continue to rise, the temperature is raised to 90°C, and the temperature is kept at this temperature for half an hour;

[0048] Adjust the pH to 4.7 with an acidic solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com