A kind of ultraviolet curing pressure-sensitive adhesive and preparation method thereof

A technology of ultraviolet light and curing pressure, applied in adhesives, non-polymer organic compound adhesives, adhesive additives, etc., can solve the problem of slow drying and film formation, poor heat resistance, and restrictions on the large-scale development and application of HMPSA, etc. problems, achieve the effect of reducing energy waste and fast cross-linking speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

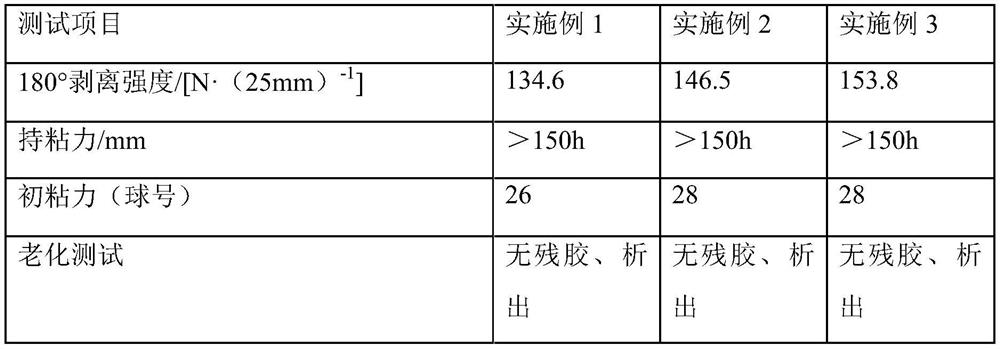

Examples

Embodiment 1

[0026] In every 100 mass parts raw material liquid: butyl acrylate: 24.2g, isooctyl acrylate: 8g, neopentyl glycol diacrylate: 10g, pentaerythritol triacrylate: 12g, acrylate polyol (hydroxyl value 18mgKOH / g ): 40 g, 200 nm fumed silica: 3 g, hydroxycyclohexyl phenyl ketone: 2 g, γ-(methacryloyloxy)propyltrimethoxysilane: 0.8 g.

[0027] The preparation method is:

[0028] Under the conditions of avoiding sunlight and relative air humidity of less than 60%, add the above-mentioned substances into the mixing tank in turn, stir for 30 minutes, and then filter and remove impurities with a polypropylene filter element with a pore size of 0.1 μm to obtain a raw material mixture for later use. .

[0029] Then the prepared raw material mixture is coated on the PET film substrate by slit extrusion coating method, and the irradiation energy of the ultraviolet high-pressure mercury lamp is 800mJ / cm 2 After being irradiated for 15s, it is cured to form a layer of pressure-sensitive adh...

Embodiment 2

[0031] In every 100 parts by mass of raw material liquid: butyl acrylate: 30g, ethylene glycol diacrylate: 12g, trimethylolpropane pentaerythritol triacrylate: 6g, polyurethane acrylate (hydroxyl value 18mgKOH / g): 46.2g, 200 nm fumed silica: 3 g, hydroxycyclohexyl phenyl ketone: 2 g, γ-(methacryloyloxy)propyltrimethoxysilane: 0.8 g.

[0032] The preparation method is:

[0033] Under the conditions of avoiding sunlight and relative air humidity less than 60%,

[0034] The above-mentioned substances were sequentially added into the mixing tank, stirred for 30 minutes, and then filtered through a polypropylene filter element with a pore size of 0.1 μm to remove impurities to obtain a raw material mixture, which was set aside.

[0035] Then the prepared raw material mixture is coated on the PET film substrate by slit extrusion coating method, and the irradiation energy of the ultraviolet high-pressure mercury lamp is 800mJ / cm 2 After being irradiated for 15s, it is cured to form...

Embodiment 3

[0037] In every 100 parts by mass of raw material liquid: butyl acrylate: 25g, vinyl acetate: 16g, ethylene glycol diacrylate: 7g, trimethylolpropane pentaerythritol triacrylate: 8g, polyurethane acrylate (hydroxyl value 18mgKOH / g): 35.2 g, 200 nm fumed silica: 5 g, hydroxycyclohexyl phenyl ketone: 3 g, γ-(methacryloyloxy)propyltrimethoxysilane: 0.8 g.

[0038] The preparation method is:

[0039] Under the conditions of avoiding sunlight and relative air humidity of less than 60%, add the above-mentioned substances into the mixing tank in turn, stir for 30 minutes, and then filter and remove impurities with a polypropylene filter element with a pore size of 0.1 μm to obtain a raw material mixture for later use. .

[0040] Then the prepared raw material mixture is coated on the PET film substrate by slit extrusion coating method, and the irradiation energy of the ultraviolet high-pressure mercury lamp is 800mJ / cm 2 After being irradiated for 15s, it is cured to form a layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com