Preparation method of aqueous adhesive for lithium-ion batteries

A technology for water-based binders and lithium-ion batteries, which can be used in non-polymer binder additives, secondary batteries, battery electrodes, etc. Issues such as weak force of active materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

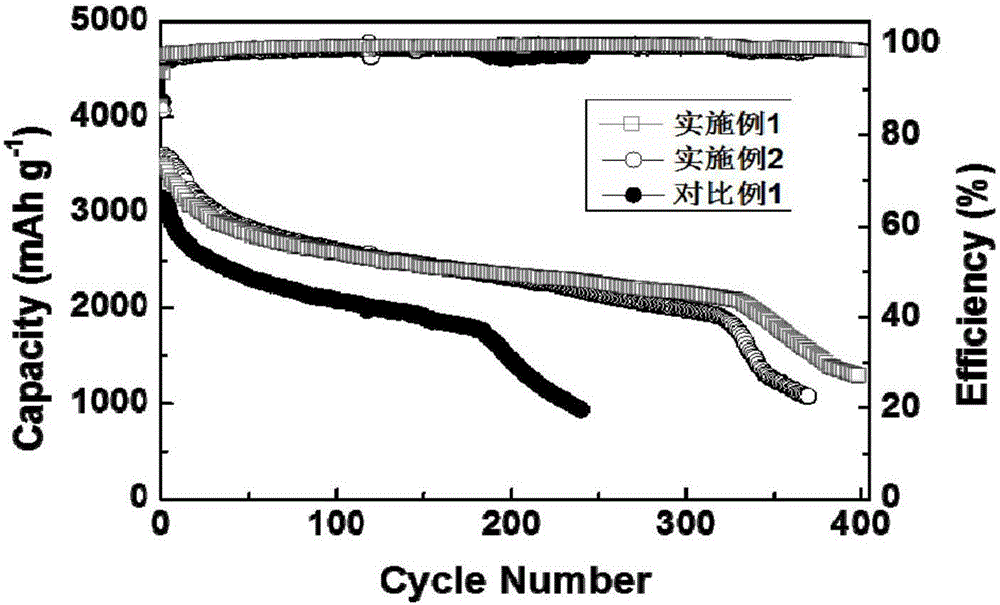

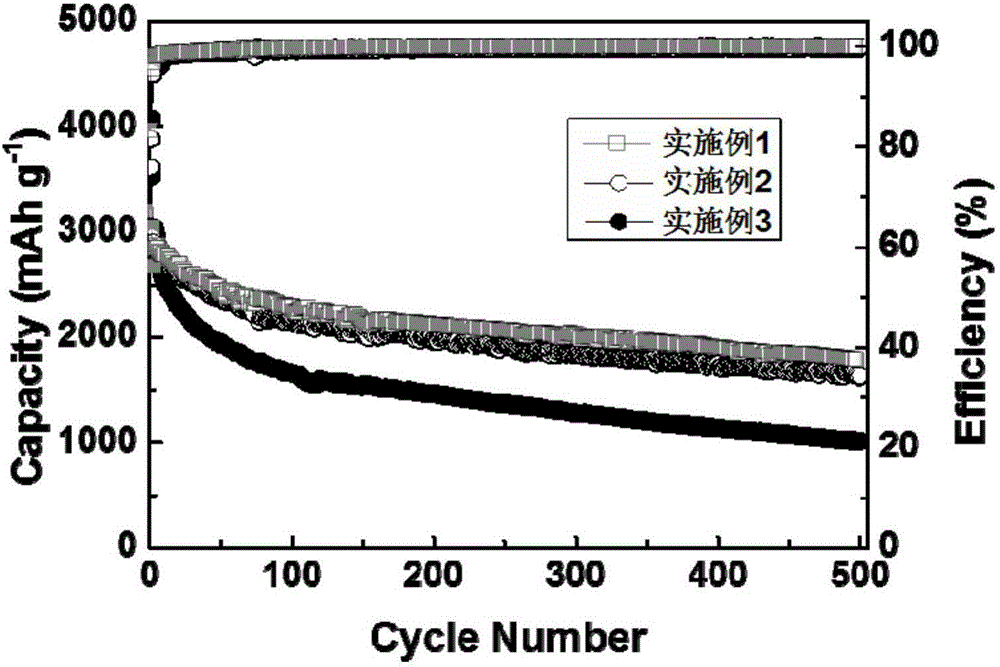

Embodiment 1

[0026] Prepare aluminum sulfate to make aluminum ion concentration 1.8mmol L -1 aqueous solution as a crosslinking agent. Weigh 0.02 g of sodium alginate and 1 mL of cross-linking agent in a weighing bottle and stir and mix until a uniform, transparent gel is formed. Weigh 0.06g of nano-silicon and 0.02g of acetylene black, grind and mix them in a mortar until they are uniform, then transfer them to a weighing bottle and mix them with the gel obtained before, and keep stirring for 6-12 hours until a homogeneous slurry is formed. Cut the copper foil with a thickness of 15 μm into copper sheets with a diameter of 12 mm, wash with 10 wt % hydrochloric acid, deionized water, and acetone in sequence and dry under vacuum at room temperature. Then weigh and record the mass of each copper sheet. The resulting homogenate was uniformly coated on the above-mentioned copper sheet, and then vacuum-dried at 80° C. for 10 h. The pole pieces obtained after drying were weighed and transferr...

Embodiment 2

[0028] Different from Example 1 is that barium chloride is mixed with barium ion concentration 1.8mmol L -1 aqueous solution as a crosslinking agent.

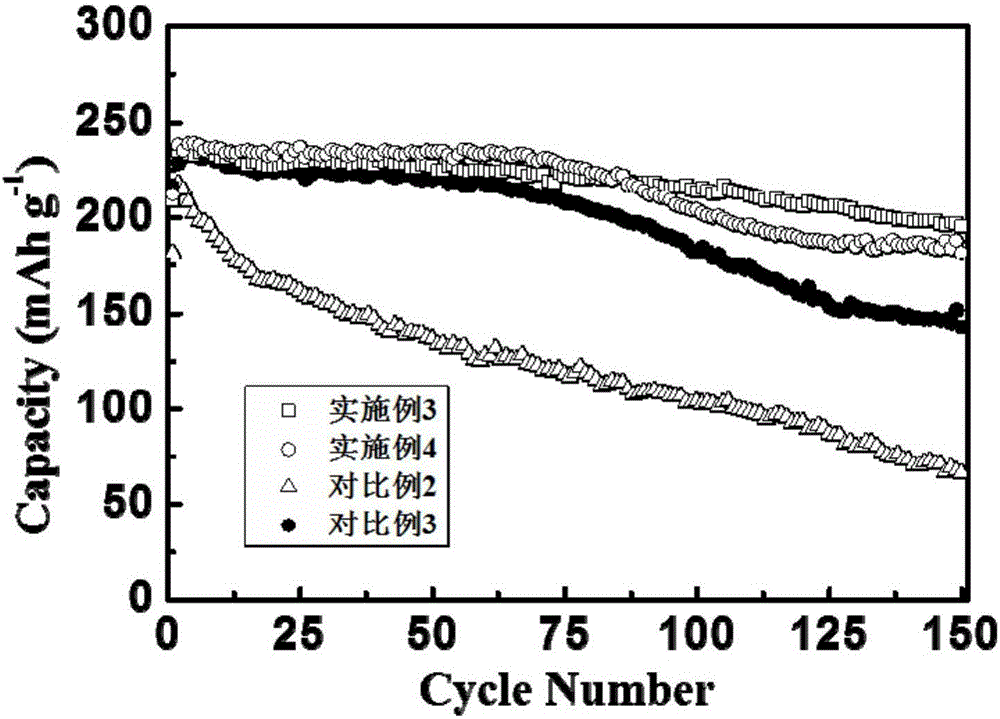

Embodiment 3

[0030] Barium chloride was formulated to have a barium ion concentration of 1.8mmol L -1 aqueous solution as a crosslinking agent. Weigh 0.02 g of sodium alginate and 1 mL of cross-linking agent in a weighing bottle and stir and mix until a uniform, transparent gel is formed. Weigh the lithium-rich manganese-based cathode material Li 1.16 mn 0.6 Ni 0.12 co 0.12 o 2 0.16g and 0.02g of BP 2000 were ground and mixed in a mortar until uniform, then transferred to a weighing bottle and stirred and mixed with the gel obtained before, and kept stirring for 6-12 hours until a homogeneous slurry was formed. Aluminum foil with a thickness of 20 μm was cut into aluminum sheets with a diameter of 12 mm, washed with 10 wt % oxalic acid solution, deionized water, and acetone in sequence, and then dried. Then weigh and record the mass of each aluminum sheet. The resulting homogenate was uniformly coated on the above-mentioned aluminum sheet, and then vacuum-dried at 100° C. for 10 h....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com