Anti-explosion impact polyurea coating and preparation method thereof

A coating and polyurea technology, which is applied in the field of explosion-proof impact polyurea coating and its preparation, can solve the problems of low temperature flexibility and high tearing, and achieve the effects of stable performance, good low temperature flexibility and enhanced performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The formulation of the anti-explosion impact polyurea coating in this implementation case is as follows:

[0028] A component

[0029] MDI-50 50

[0030] MS-202 (polycarbonate polyol) 45

[0031] Modified graphene slurry 5

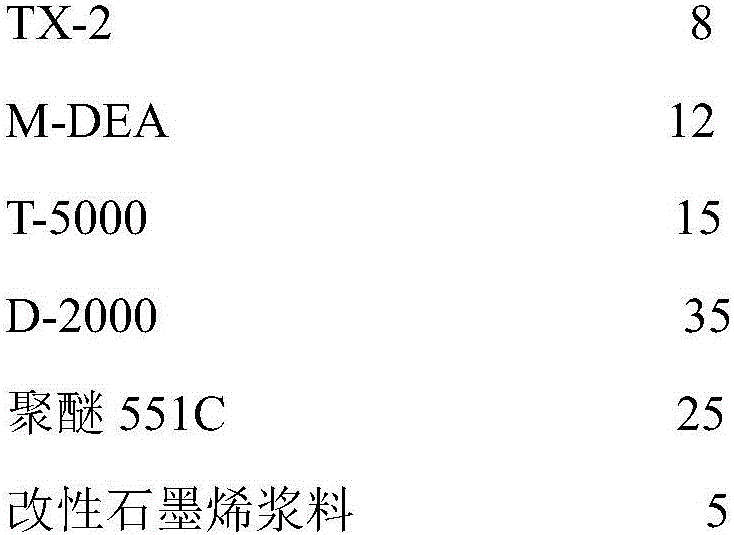

[0032] B component

[0033]

[0034]

[0035] Preparation of modified graphene slurry: mix natural flake graphite (Qingdao Hexing, 800 mesh) with sodium nitrate and add to the reaction vessel, add concentrated sulfuric acid, react at room temperature for 2 hours, add potassium permanganate, heat up to 40°C for 3 hours Then add deionized water and raise the temperature to 90°C, add hydrogen peroxide, wash and dry, then mix it with MDI-50, DMF, aminosilane KH550, and then ultrasonically disperse it, then vacuum dry at 90°C and extract the solvent to obtain a solvent-free liquid graphene slurry material.

[0036] Add 45 parts of MS-202 into the reaction kettle, then add 5 parts of modified graphene slurry, heat to 110°C for 3 hours and then ...

Embodiment 2

[0042] A component

[0043]

[0044] B component

[0045]

[0046]

[0047] Add 50 parts of MS-650B and 5 parts of modified graphene slurry into the reaction kettle, heat to 110 degrees and vacuumize for 3 hours, then add 30 parts of MDI-100, 15 parts of H 12MDI (hydrogenated MDI), reacted at 105°C for 3 hours to obtain the semi-prepolymer A component.

[0048] Add component B to the mixing tank in turn and stir evenly, and grind in a sand mill for 2.5 hours to obtain component B.

[0049] Components A and B are sprayed with a high-pressure sprayer, and the two components of A and B are transported to the main engine through a pump, heated and pressurized and accurately measured, mixed evenly in a dynamic mixing chamber, sprayed on the surface and cured quickly forming. According to the conditions specified in GB9278, the performance measurement was performed after being placed for 7 days.

[0050] Table 2 performance measurement results

[0051] Tensile...

Embodiment 3

[0053] Prescription is with embodiment 2

[0054] The components A and B of Example 2 are poured with a low-pressure pouring machine. After the two components enter the proportional pump through the storage tank and are accurately metered, they are mixed in a high-speed spiral at the pouring head, extruded or injected onto a plastic formwork for solidification and molding.

[0055] According to the conditions specified in GB9278, the performance measurement was performed after being placed for 7 days.

[0056] Table 3 performance measurement results

[0057] Tensile Strength 42MPa Elongation 350% Surface dry time 18S tear strength 123kN / m Low temperature resistance No cracking at -50℃

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Surface dry time | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com