Preparation process of high-activity papain

A papain, high-activity technology, applied in the field of preparation of high-activity papain, can solve problems such as unfavorable purification, residual salting-out solvents, and reduced protease activity, so as to facilitate digestion and absorption and improve nutritional value , The effect of simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

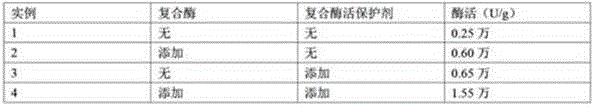

Examples

Embodiment 1

[0038] This embodiment does not add compound enzyme and compound enzyme activity protector.

[0039] The concrete operating steps of preparing a kind of highly active papain are as follows:

[0040] (1) Fresh papaya, peeled and young, divided into small pieces, added distilled water at a mass ratio of 1:1, squeezed and beaten for 3 minutes to obtain papaya pulp.

[0041] (2) Use 120-mesh double-layer filter cloth, filter with suction, remove the filter residue, and get fresh papaya juice.

[0042] (3) Centrifuge the fresh papaya juice, take the supernatant, and refrigerate it for later use. The rotation speed is 3500rpm and the time is 15min. The refrigerated condition is 4°C.

[0043] (4) Add 75% ethanol to the supernatant at a volume ratio of 1:1, and let it stand for 10 hours to obtain a solution.

[0044] (5) The solution was centrifuged to obtain a precipitate, and freeze-dried to a constant weight to obtain a crude product of papain. Wherein the centrifugal speed is ...

Embodiment 2

[0047] In this example, compound enzymes are added, but no compound enzyme activity protector is added.

[0048] The concrete operating steps of preparing a kind of highly active papain are as follows:

[0049] (1) Fresh papaya, peeled and young, divided into small pieces, added distilled water at a mass ratio of 1:1, squeezed and beaten for 3 minutes to obtain papaya pulp.

[0050] (2) Add compound enzyme to Xuan papaya pulp, the amount of compound enzyme added is 0.9% of the mass of Xuan papaya pulp; compound enzyme is composed of cellulase and pectinase in a mass ratio of 8:1, stir evenly, and heat at 50°C Under enzymatic hydrolysis reaction 1.5h.

[0051] (3) Use 120-mesh double-layer filter cloth, filter with suction, remove the filter residue, and get fresh papaya juice.

[0052] (4) Centrifuge the obtained fresh papaya juice at 3500rpm for 15min, take the supernatant, and refrigerate at 4°C for later use.

[0053] (5) Add 75% ethanol to the supernatant at a volume ra...

Embodiment 3

[0056] This embodiment does not add compound enzyme, but adds compound enzyme activity protector

[0057] The concrete operating steps of preparing a kind of highly active papain are as follows:

[0058] (1) Fresh papaya, peeled and young, cut into small pieces, added distilled water at a mass ratio of 1:1, squeezed and beaten for 3 minutes to obtain papaya pulp.

[0059] (2) Use 120-mesh double-layer filter cloth, filter with suction, remove the filter residue, and get fresh papaya juice.

[0060] (3) Centrifuge the obtained fresh papaya juice at 3500rpm for 15min, take the supernatant, and refrigerate at 4°C for later use.

[0061](4) Add 75% ethanol and compound enzyme protection agent to the supernatant, adjust the pH value to 7.0 with 0.1mol / L sodium hydroxide (NaOH), and let it stand for 10 hours to obtain a compound solution. The mass ratio of ethanol to supernatant was 1:1, the addition amount of ethylenediaminetetraacetic acid (EDTA) was 0.004mol / L, and the addition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com