Coal shaft furnace direct reduction process

A coal-based, shaft furnace technology, applied in shaft furnaces, improvement of process efficiency, furnaces, etc., can solve problems such as production constraints, unreasonable furnace top material distribution system, complex process, etc., to achieve large transportation and material distribution capabilities, and optimize the furnace The effect of topping fabric technology and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

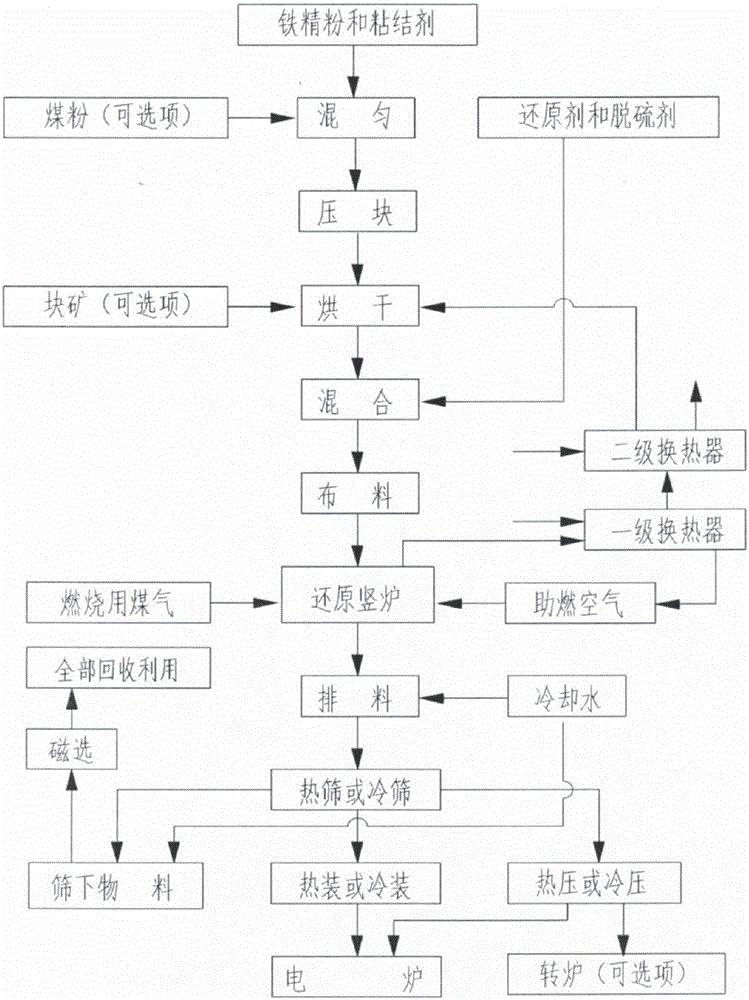

[0047] Such as figure 1 As shown, the invention provides a kind of coal-based shaft furnace direct reduction process for producing sponge iron, and its main production steps include:

[0048] 1) The iron concentrate powder and binder are fully mixed and then briquetted. The particle size of the briquette is 15-45mm, then dried, and mixed with reducing agent and desulfurizer after drying; iron concentrate powder and binder During the mixing process, a small amount of coal powder can be added as needed to improve the reduction efficiency; if the raw material is lump ore, there is no need for mixing and briquetting, and the drying and subsequent processes are directly carried out;

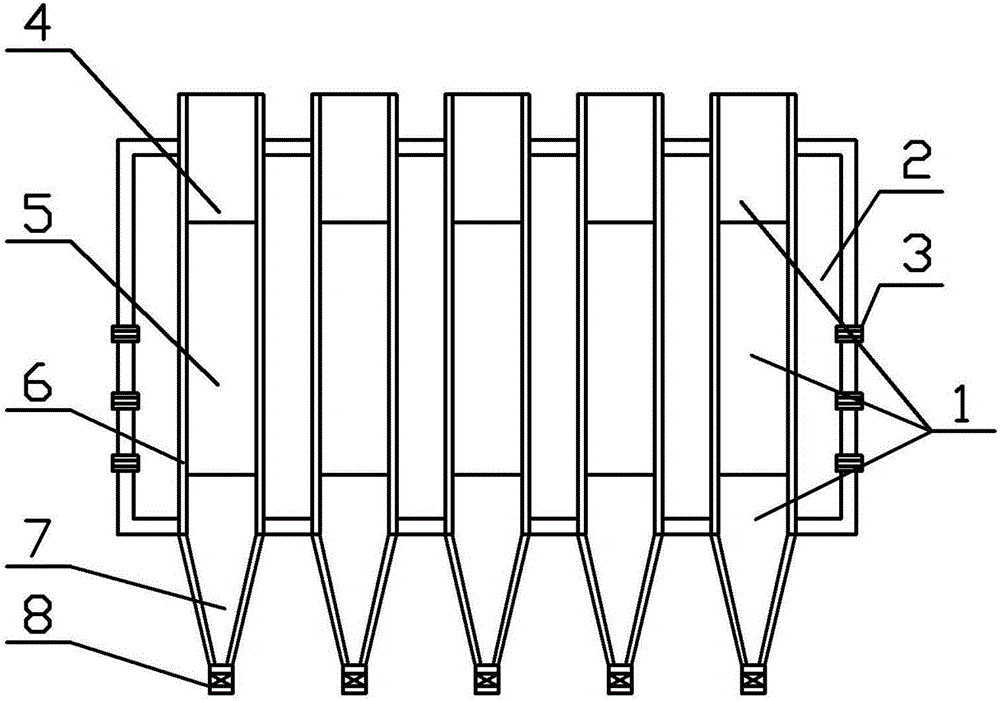

[0049] 2) The mixture is fed from the top of the reduction chamber by the material distribution device of the coal-based shaft furnace. The reduction chamber is completely filled with the mixture. The materials are dispersed and evenly distributed. The material surface is higher than the reduction fu...

Embodiment 2

[0065] The coal-based shaft furnace direct reduction process for producing sponge iron of the present invention comprises the following steps:

[0066] 1) Fully mix the iron fine powder with iron content of 64% and binder, and then briquette. The particle size after briquetting is about 25mm. After being dried by a dryer, it is transported to the silo under the tank;

[0067] 2) Mix the dried block material obtained above with anthracite reducing agent and limestone desulfurizer. It is required to mix as evenly as possible. The ratio of block material to reducing agent is about 1:0.4. The mixture is loaded from the top of the reduction furnace by the furnace top distributor. into the reduction chamber, the mixture will completely fill the reduction chamber and be higher than the top surface of the reduction furnace by a certain height;

[0068] 3) The preheating section and reducing section of the reduction chamber are rectangular, with a width of 300-800mm, a length of 1000-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com