Method for metallic arsenic production directly through reducing sulfur-fixed roasting of arsenic precipitating slag

A technology for metal arsenic and roasting products, applied in the direction of improving process efficiency, can solve the problems of ineffective utilization of arsenic resources, high cost of raw material preparation, and large environmental pollution, and achieve efficient and harmless utilization, high product value, comprehensive good recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

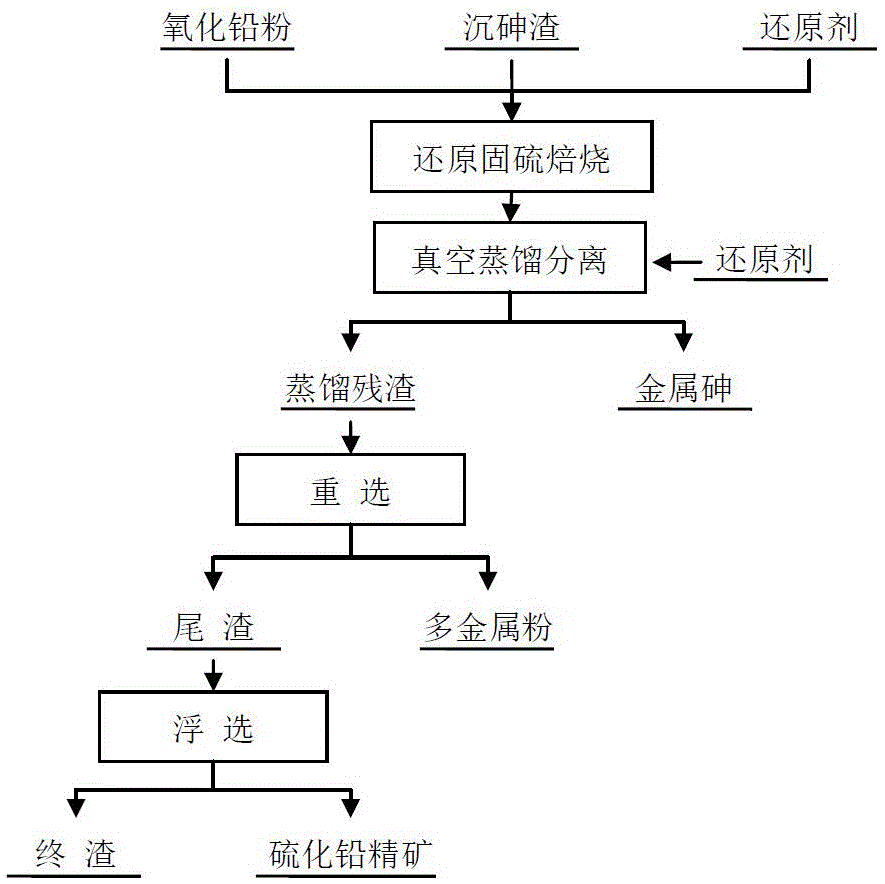

[0047] Process flow chart of the present invention is attached figure 1 shown.

[0048] The main components of the arsenic residue (dry residue) used as the experimental raw material are (wt.%): S 27.24, As 19.26, Cu0.37, Pb 3.86, Bi 0.070, Fe 1.02, Zn0.19, Ni 0.08, Cd 1.3, Se 0.81; the chemical composition (wt. %) of reduced coke powder is: C86.56, S2.79, SiO 2 5.17, CaO1.03, Al 2 o 3 3.94, MgO0.42; lead oxide powder is chemically pure grade reagent.

[0049] S1. Weigh 200g of arsenic slag, 40g of lead oxide powder, and 10g of coke powder of the above ingredients, mix all the materials evenly, put them into a corundum crucible, put them into a vacuum furnace and roast at 400°C for 2.0h;

[0050] S2. Add 2g of coke powder to the roasted product in the vacuum furnace in step S1, raise the temperature of the vacuum furnace to 700°C, turn on the vacuum system, distill for 2.0h under the condition of a vacuum degree of 10Pa, and condense at the same time to separate the metal ...

Embodiment 2

[0055] Experimental raw materials, reagents and steps are the same as in Example 1.

[0056] S1. Weigh 200g of arsenic precipitation slag, 70g of lead oxide powder, and 20g of coke powder of the above ingredients, mix all the materials evenly, put them into a corundum crucible, put them into a vacuum furnace and roast at 500°C for 1.0h;

[0057] S2. Add 6g of coke powder to the roasted product in the vacuum furnace in step S1, raise the temperature of the vacuum furnace to 700°C, turn on the vacuum system, distill for 2.0h under the condition of a vacuum degree of 10Pa, and condense at the same time to separate and obtain metallic arsenic and distillation residues;

[0058] Condensation has been carried out to collect volatiles throughout the reduction sulfur fixation roasting process and vacuum distillation process.

[0059] The mass of the finally collected volatile matter and metal arsenic was 37.12g, the content of arsenic was analyzed to be 92.25%, and the direct recover...

Embodiment 3

[0062] Experimental raw materials, reagents and steps are the same as in Example 1.

[0063] S1. Weigh 200g of arsenic precipitation slag, 100g of lead oxide powder, and 40g of coke powder of the above ingredients, mix all the materials evenly, put them into a corundum crucible, put them into a vacuum furnace and roast at 300°C for 4.0h;

[0064] S2. Add 6g of coke powder to the roasted product in the vacuum furnace in step S1, raise the temperature of the vacuum furnace to 800°C, turn on the vacuum system, distill for 4.0h under the condition of a vacuum degree of 20Pa, and condense at the same time to separate and obtain metallic arsenic and distillation residues;

[0065] Condensation has been carried out to collect volatiles throughout the reduction sulfur fixation roasting process and vacuum distillation process.

[0066] The mass of the finally collected volatile matter and metallic arsenic was 34.89g, the arsenic content was 96.11% in the analysis, and the direct recov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com