Fluorine-containing antibacterial coating on the surface of metal materials and preparation method thereof

A metal material, antibacterial coating technology, applied in the direction of metal material coating process, coating, pharmaceutical formulation, etc., to achieve the effect of broad-spectrum antibacterial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

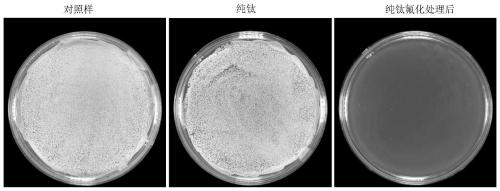

[0060] A fluorine-containing antibacterial coating on the surface of a metal material, the coating composition includes fluorine element and R-F compound, and the coating has nano-scale holes; wherein, R is titanium, the size of the nano-scale holes is 50-200nm, and the nano-scale The volume of the pores accounts for 60% of the coating volume.

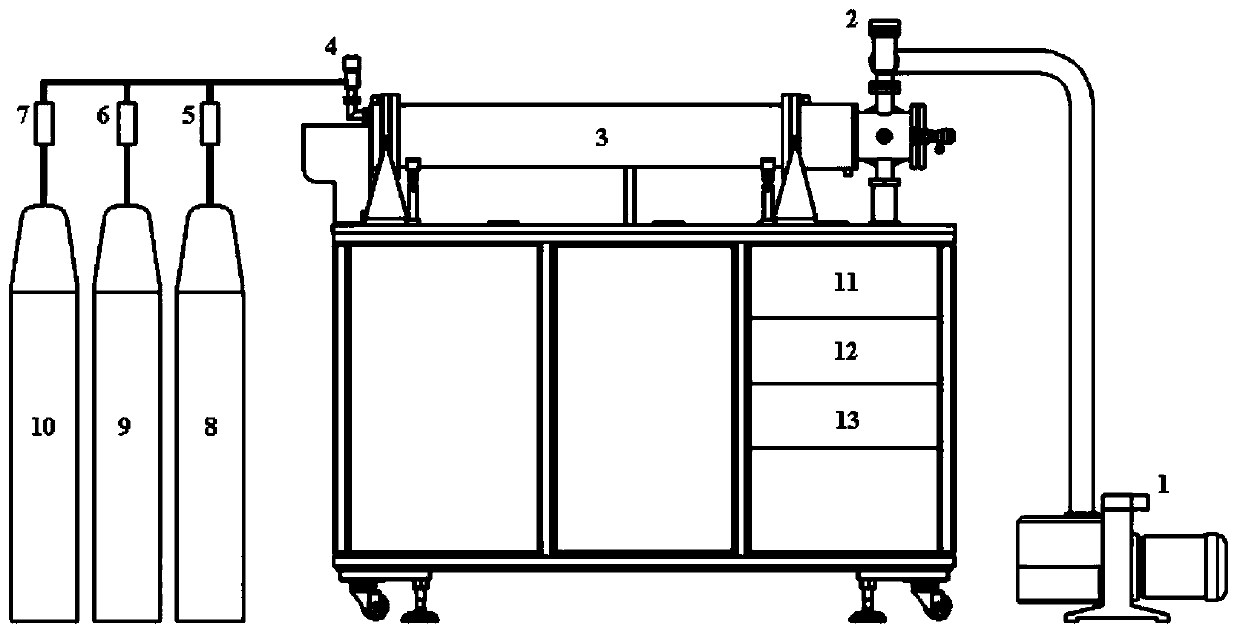

[0061] The preparation method of the above-mentioned fluorine-containing antibacterial coating on the surface of metal material titanium adopts a P150B controllable atmosphere plasma material surface treatment device, and the preparation includes the following steps:

[0062] Step 1, surface pretreatment:

[0063] Use chemical methods of mechanical grinding or acid-base treatment to remove the oil and oxide layer of metal materials, so that the surface of metal materials is smooth and clean;

[0064] Step 2, vacuum preparation:

[0065] Place the metal material in the plasma reaction chamber of the controllable atmosphere plasma mate...

Embodiment 2

[0077] A fluorine-containing antibacterial coating on the surface of a metal material, the coating composition includes oxygen element, fluorine element, R-F compound and R-O compound, and the coating has a nanoscale raised structure; wherein, R is titanium, and the nanoscale raised The size of the structure is 100-300nm, and the volume of the nanoscale hole accounts for 50% of the volume of the coating.

[0078] The preparation method of the fluorine-containing antibacterial coating on the surface of the metal material titanium adopts the same device as in Example 1, and the difference between the preparation method and Example 1 is that in step 4, argon, oxygen and tetrachloride are simultaneously introduced into the plasma reaction chamber. Fluorocarbon gas, wherein, the argon gas flow rate is 20 sccm, the carbon tetrafluoride gas flow rate is 2.0 sccm, the ratio of argon gas to oxygen gas is: 1, and other parts are exactly the same as in Example 1.

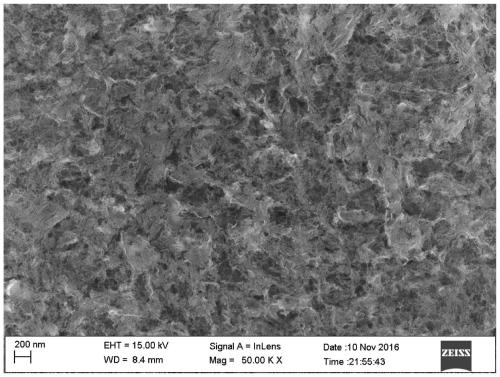

[0079] The scanning el...

Embodiment 3

[0083] A fluorine-containing antibacterial coating on the surface of a metal material, the coating composition includes oxygen elements, fluorine elements, R-F compounds and R-O compounds, and the coating has a composite structure of nanoscale holes and nanoscale protrusions; wherein, R is titanium , the size of the nano-scale hole is 50-100nm, the size of the nano-scale protrusion is 50-100nm, and the composite structure of the nano-scale hole and the nano-scale protrusion accounts for 40% of the coating volume.

[0084] The preparation method of above-mentioned metal material titanium surface fluorine-containing antibacterial coating adopts device with embodiment 1, and the difference of preparation method and embodiment 1 is that in step 4, feed argon, oxygen and Carbon tetrafluoride gas, wherein, the argon gas flow rate is 5 sccm, the carbon tetrafluoride gas flow rate is 5.0 sccm, the ratio of argon gas to oxygen gas is: 1, and other parts are exactly the same as in Exampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com