Method for preparing BaTiO3/TiO2 nano-composite thin film material

A thin-film material and nano-composite technology, applied in metal material coating process, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of long reaction cycle, coarse product grains, low energy utilization rate, etc., and achieve high heating rate Fast, uniform distribution, and excellent photogenerated cathodic protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] a BaTiO 3 / TiO 2 The preparation method of nanocomposite film material, comprises the steps:

[0029] (1) Sample pretreatment: Ultrasonic cleaning the titanium foil with acetone, ethanol and deionized water for 10 minutes respectively, and immersing the cleaned titanium foil in the chemical polishing solution for polishing treatment for 30 seconds, wherein the volume ratio of each component of the chemical polishing solution for HF:HNO 3 :H 2 O=1:3:16, after polishing, blow dry with a hair dryer and dry at 60°C;

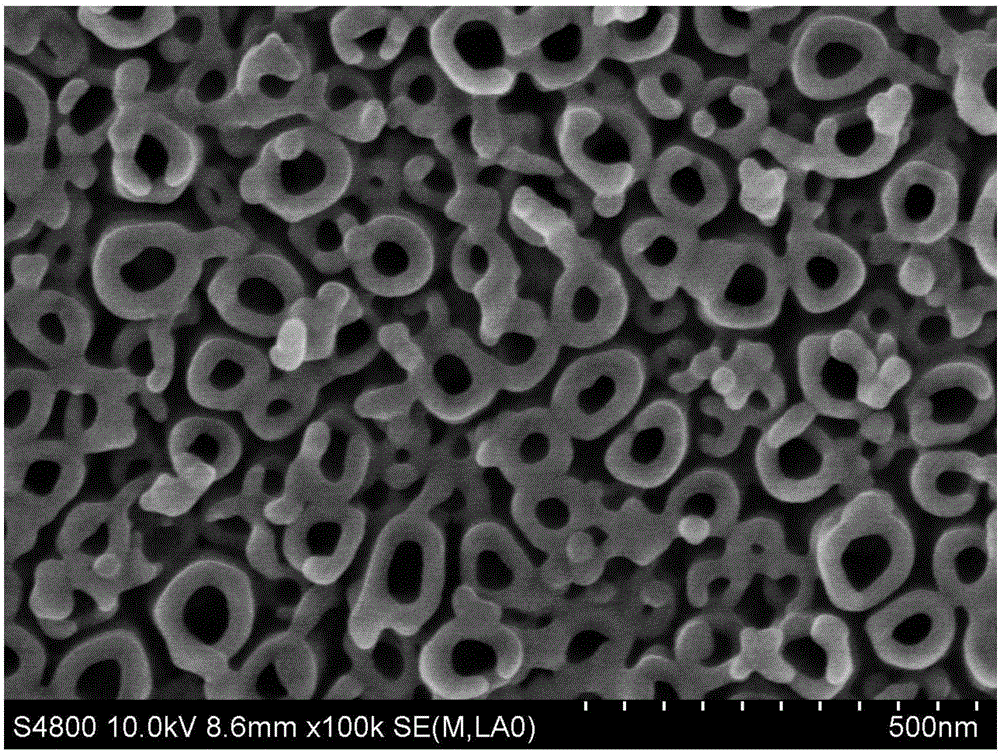

[0030] (2) Preparation of TiO on the surface of titanium foil by anodic oxidation 2 Nanotube: use platinum sheet as cathode, titanium foil as anode, anodize at 20V oxidation voltage for 0.5h; the distance between the two electrodes is 2cm, the temperature is room temperature, and the electrolyte is 0.5wt%NH 4 F, 40wt%H 2 Glycerol solution of O; after anodizing, wash the titanium foil with a large amount of deionized water to remove the residual electroly...

Embodiment 2

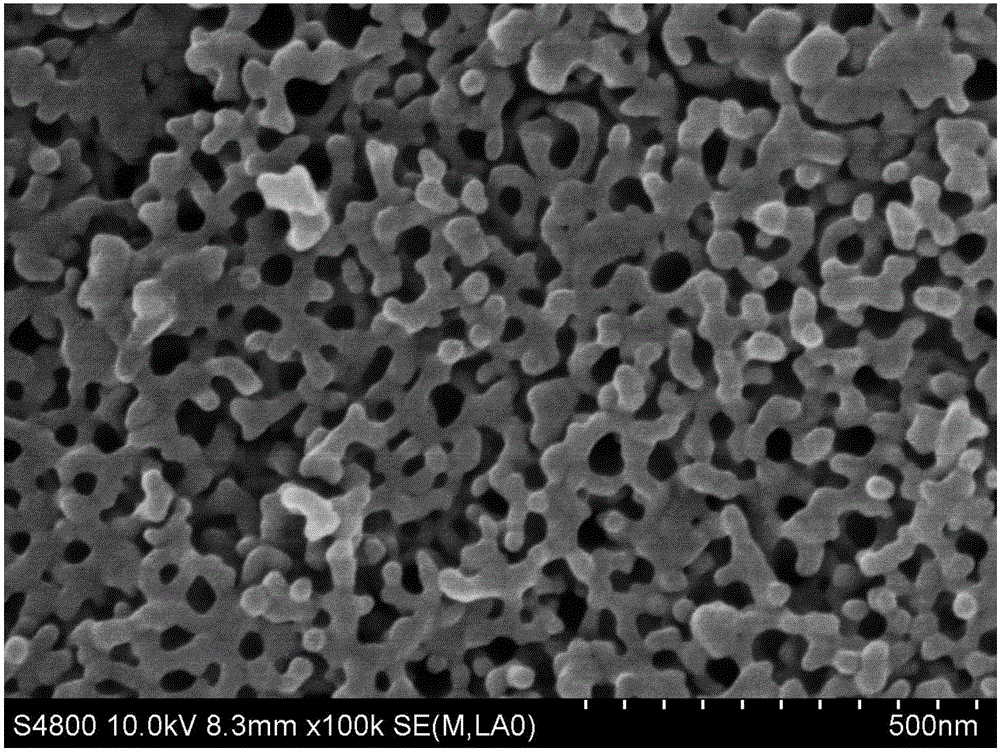

[0033] This embodiment prepares BaTiO 3 / TiO 2 The method of nanocomposite thin film material is roughly the same as embodiment 1, and difference is that step (3) microwave hydrothermal method prepares BaTiO 3 / TiO 2 Nanocomposite thin-film materials: utilizing CO removal 2 prepared Ba(OH) at a concentration of 0.05M with deionized water 2 Solution, by volume ratio is 40%, will Ba(OH) 2 The solution is poured into the reaction bottle of the microwave hydrothermal synthesizer, and then the obtained TiO2 grown in step (2) is added. 2 For the titanium foil of nanotubes, set the power of the microwave hydrothermal reaction instrument to 800W, the heating rate to 20°C / min, the reaction temperature to 120°C, and the holding time to 30min. After the reaction is complete and cooled to room temperature, the titanium foil is taken out and immersed in The concentration is 1M HCl solution for 1 min.

Embodiment 3

[0035] This embodiment prepares BaTiO 3 / TiO 2 The method of nanocomposite thin film material is roughly the same as embodiment 1, and difference is that step (3) microwave hydrothermal method prepares BaTiO 3 / TiO 2 Nanocomposite thin-film materials: utilizing CO removal 2 of deionized water to prepare Ba(OH) at a concentration of 0.1M 2 Solution, by volume ratio is 50%, will Ba(OH) 2 The solution is poured into the reaction bottle of the microwave hydrothermal synthesizer, and then the obtained TiO2 grown in step (2) is added. 2 For titanium foil of nanotubes, set the power of the microwave hydrothermal reaction instrument to 400W, the heating rate to 10°C / min, the reaction temperature to 150°C, and the holding time to 30min. After the reaction is complete and cooled to room temperature, the titanium foil is taken out and immersed in The concentration is 1M HCl solution for 1 min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com