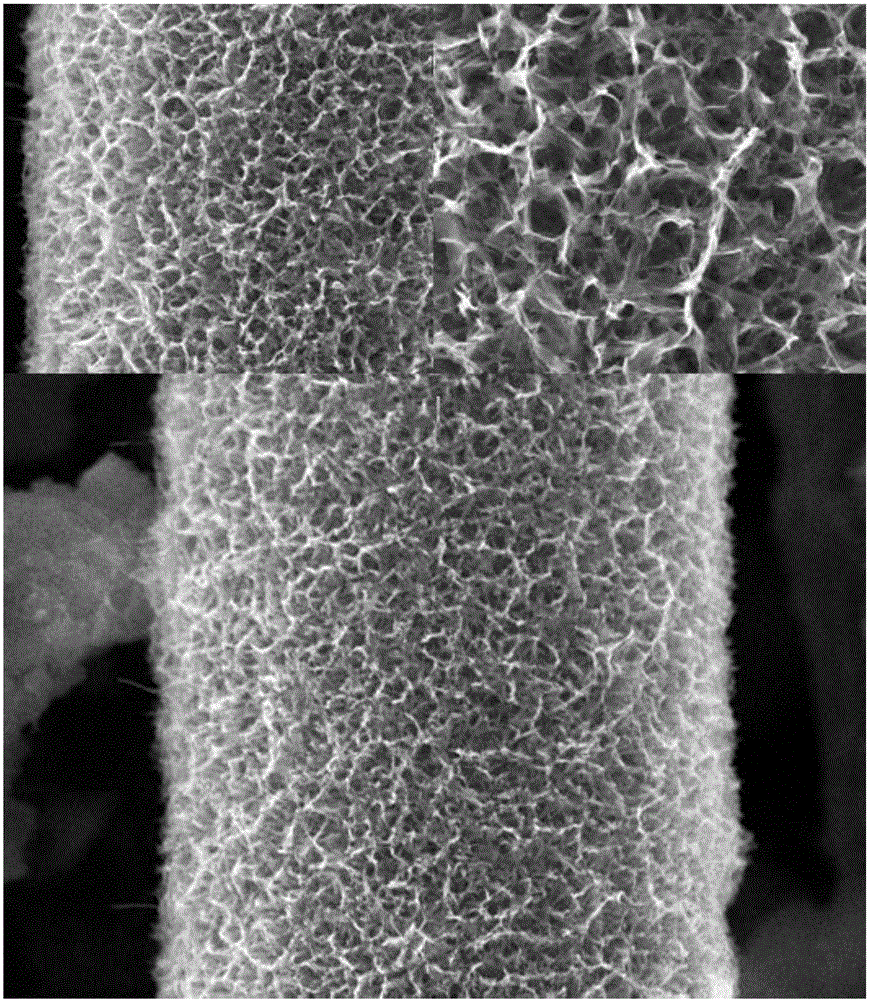

Super-thin-wall honeycomb-shaped structure titanium dioxide nano material and preparation method thereof

A technology of titanium dioxide and nanomaterials, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of large thickness of titanium dioxide nanosheets, low nanosheet formation rate, complicated preparation process, etc. Short preparation time, easy to popularize and apply, and the effect of reducing the pollution of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Measure 50ml of absolute ethanol into a beaker, slowly add 10ml of tetrabutyl titanate under magnetic stirring, then add 1.2ml of glacial acetic acid dropwise, and stir for 30min. A yellow sol was formed. Measure 0.6ml of deionized water with a pipette gun. Stir vigorously at room temperature for 48 hours to form a milky white titanium dioxide sol. Soak the carbon fiber cloth in the titanium dioxide sol to prepare a layer of titanium dioxide nano-film layer, and put it into an annealing furnace at 450°C for 30 minutes for annealing.

[0032] (2) preparing a two-dimensional titanium dioxide nanostructure layer with controllable void size and shape on the titanium dioxide nano seed layer prepared in step (1). Use deionized water, sodium hydroxide, and graphene to configure a mixed solution, put the prepared titanium dioxide nano-film layer carbon fiber cloth into the mixed solution, introduce the mixed solution into the inner lining of the autoclave, and then place th...

Embodiment 2

[0034] (1) Measure 40ml of absolute ethanol into a beaker, slowly add 10ml of tetrabutyl titanate under magnetic stirring, then add 1.2ml of glacial acetic acid dropwise, and stir for 30min. A yellow sol was formed. Measure 0.6ml of deionized water with a pipette gun. Stir vigorously at room temperature for 48 hours to form a milky white titanium dioxide sol. Soak the carbon fiber cloth in the titanium dioxide sol to prepare a layer of titanium dioxide nano-film layer, and put it into an annealing furnace at 600°C for 60 minutes for annealing.

[0035] (2) preparing a two-dimensional titanium dioxide nanostructure layer with controllable void size and shape on the titanium dioxide nano seed layer prepared in step (1). Use deionized water, sodium hydroxide, and graphene to configure a mixed solution, put the prepared titanium dioxide nano-film layer carbon fiber cloth into the mixed solution, introduce the mixed solution into the inner lining of the autoclave, and then place th...

Embodiment 3

[0037] (1) Measure 45ml of absolute ethanol into a beaker, slowly add 10ml of tetrabutyl titanate under magnetic stirring, then dropwise add 1.2ml of glacial acetic acid, and stir for 30min. A yellow sol was formed. Measure 0.6ml of deionized water with a pipette gun. Stir vigorously at room temperature for 48 hours to form a milky white titanium dioxide sol. The carbon fiber cloth is soaked in the titanium dioxide sol to prepare a layer of titanium dioxide nano film layer, which is put into an annealing furnace at 700°C for 45 minutes for annealing.

[0038](2) preparing a two-dimensional titanium dioxide nanostructure layer with controllable void size and shape on the titanium dioxide nano seed layer prepared in step (1). Use deionized water, sodium hydroxide, and graphene to configure the mixture solution, put the prepared titanium dioxide nano-film layer carbon fiber cloth into the mixture solution, introduce the mixture solution into the inner lining of the autoclave, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com