Spherical hydrogen storage alloy for capacitive nickel-hydrogen power battery and preparation method thereof

A hydrogen storage alloy and power battery technology, applied in nickel storage batteries, batteries, battery electrodes, etc., can solve problems such as damage to the morphology of alloy particles, reduced battery life, weak adhesion, etc., to eliminate spontaneous combustion and vacuum packaging, Improved cycle life and improved reaction kinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

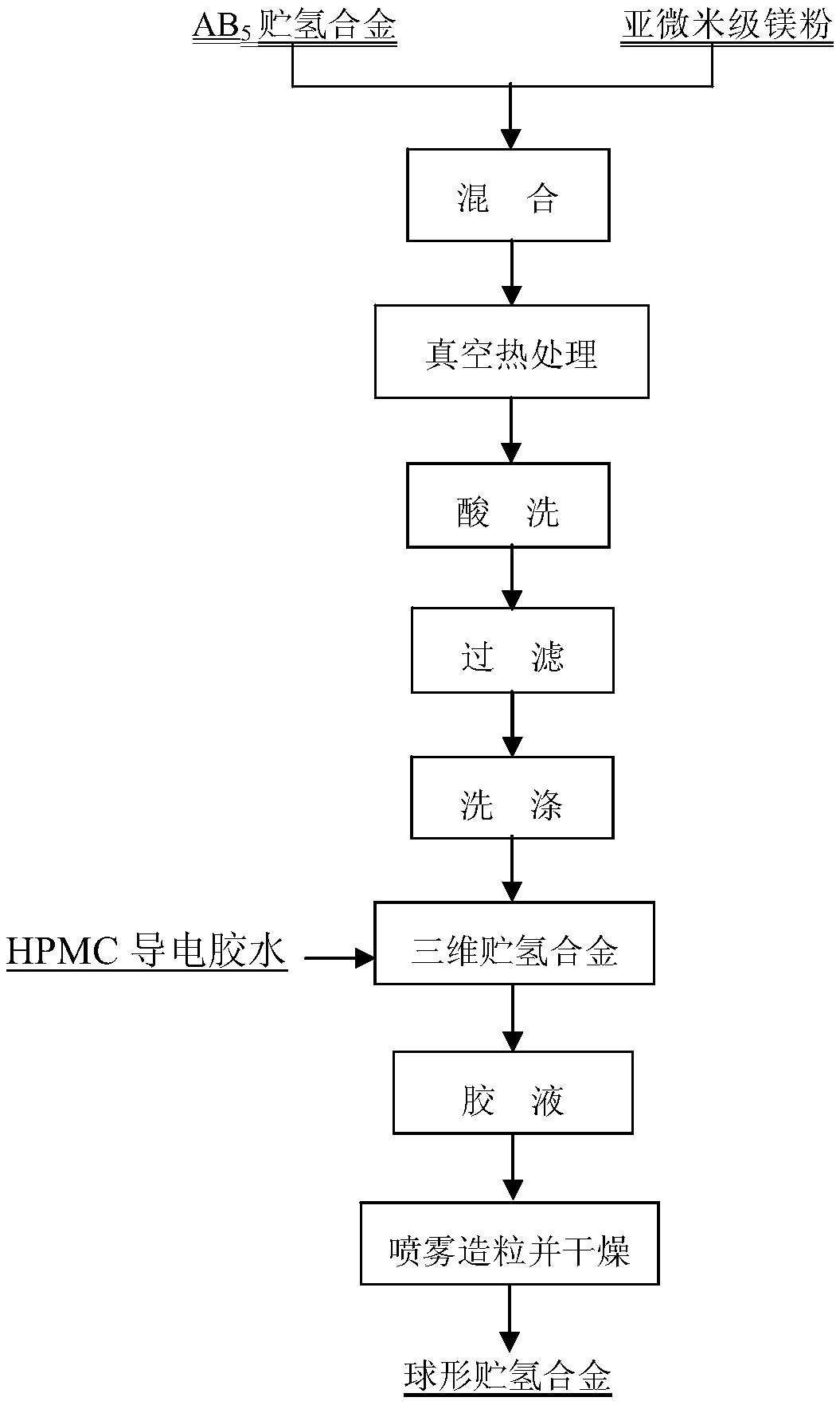

Method used

Image

Examples

Embodiment 1

[0044] a. The addition amount of submicron magnesium powder is 1% of the total mass of the hydrogen storage alloy, and the lanthanum-rich AB 5 The type hydrogen storage alloy is dry mixed with submicron magnesium powder through a cone mixer at a mixing speed of 45rpm and a mixing time of 4h. Then it is compacted and subjected to vacuum heat treatment, the heat treatment temperature is 400°C, the heating rate is 8°C / min, and the heat treatment time is 8h, and then it is naturally cooled to room temperature.

[0045] b. The vacuum heat-treated alloy is crushed by air, and then pickled under the protection of nitrogen. The pickling parameters are the acidic substance is sulfuric acid, the acid solubility is 1mol / L, the acid solution temperature is 80°C, and the treatment time is 1h; Continue to perform vacuum filtration under the protection of nitrogen to remove the acid liquid, and then wash with pure water 3 times. The waste liquid has a PH=6, which is the three-dimensional hydroge...

Embodiment 2

[0050] a. The addition amount of submicron magnesium powder is 1% of the total mass of the hydrogen storage alloy, and the cerium-rich AB 5 The type hydrogen storage alloy is dry mixed with submicron magnesium powder through a cone mixer at a mixing rate of 20 rpm and a mixing time of 2 hours. Then it is compacted and subjected to vacuum heat treatment. The heat treatment temperature is 600°C, the heating rate is 5°C / min, and the heat treatment time is 4h, and then it is naturally cooled to room temperature.

[0051] b. The vacuum heat-treated alloy is crushed by air, and then pickled under the protection of nitrogen. The pickling parameters are the acidic substance is sulfuric acid, the acid solubility is 2mol / L, the acid solution temperature is 60℃, and the treatment time is 3h; Continue to perform vacuum filtration under the protection of nitrogen to remove the acid liquid, and then wash with pure water 4 times. The waste liquid has a PH=7, which is the three-dimensional hydrog...

Embodiment 3

[0056] a. The addition amount of submicron magnesium powder is 1% of the total mass of the hydrogen storage alloy, and the lanthanum-rich AB 5 The type hydrogen storage alloy is dry mixed with submicron magnesium powder through a cone mixer at a mixing speed of 20 rpm and a mixing time of 4 hours. Then it is compacted and subjected to vacuum heat treatment. The heat treatment temperature is 500°C, the heating rate is 10°C / min, and the heat treatment time is 4h, and then it is naturally cooled to room temperature.

[0057] b. Air crush the vacuum heat-treated alloy, and then pickle it under the protection of nitrogen. The pickling parameters are acidic substance is sulfuric acid, acid solubility is 1mol / L, acid solution temperature is 70℃, and the treatment time is 2h; Continue to perform vacuum filtration under the protection of nitrogen to remove the acid liquid, and then wash with pure water 4 times. The waste liquid has a PH=7, which is the three-dimensional hydrogen storage al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com