Preparation method of a high-performance bismuth/bismuth oxide/carbon composite photocatalytic material

A photocatalytic material, bismuth oxide technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., to achieve low cost, simple process flow, and increase absorption rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: Preparation and naming of samples.

[0022] Add 10 ml of nitric acid into 290 ml of pure water, weigh 48.51 g (0.1 mol) of bismuth nitrate pentahydrate and add it to the nitric acid solution, and sonicate for 2 hours. Under vigorous stirring, 29.22 g (0.1 mol) of ethylenediaminetetraacetic acid was added to the solution, ammonium hydroxide was added to adjust the pH to 6.5, and the suspension was stirred until a clear and transparent EDTA-Bi solution was obtained. Most of the water was evaporated at 60°C using a rotary evaporator. After drying at 120℃ for 72h, EDTA-Bi was obtained as the preparation precursor of bismuth / bismuth oxide / carbon composite photocatalyst. Weigh 5 grams of the precursor and transfer it to a ceramic crucible and heat it in air for 2 hours to 300°C, 400°C, 500°C, and 600°C respectively, and the heating rate is controlled at 4°C per minute. The samples are recorded as 300, 400, 500, and 600, respectively.

Embodiment 2

[0023] Example 2: The ability of the prepared sample to degrade 2,4-dichlorophenol (2,4-DCP).

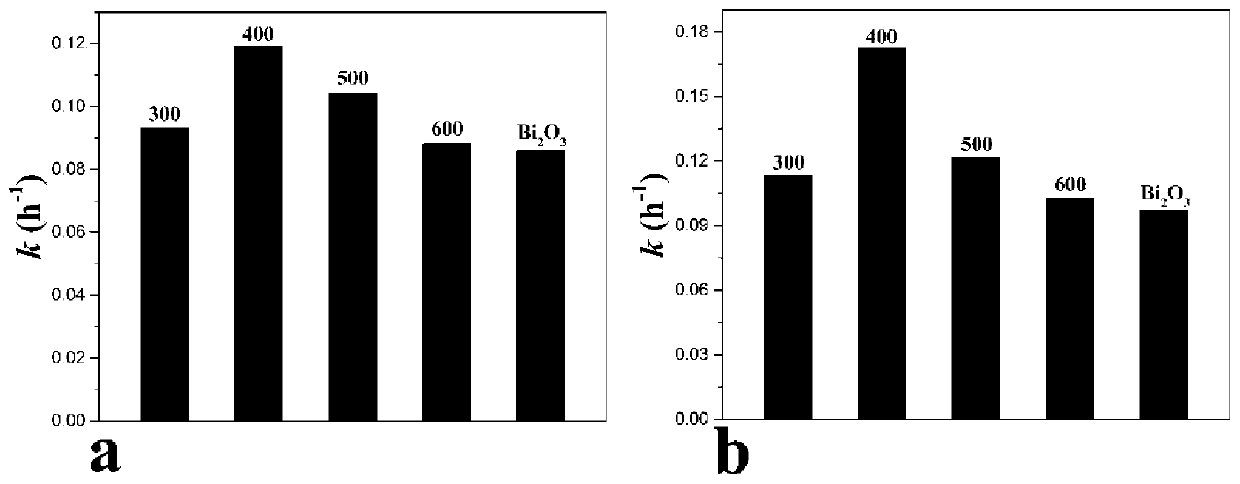

[0024] In order to investigate the degradation ability of the composite photocatalyst bismuth / bismuth oxide / carbon to colorless phenyl pollutants, 2,4-dichlorophenol was used as the target probe molecule to investigate its activity. The photocatalytic activity of the as-prepared samples was characterized by the degradation of 2,4-DCP. figure 1 a and 1b are the apparent rate constants (λ > 420 nm) and simulated sunlight irradiation for the visible light photocatalytic degradation of 2,4-DCP. It is obvious that sample 400 has the highest photocatalytic activity and organic-inorganic complexation of all samples, and the preparation method of calcination has higher photocatalytic activity than that of bismuth oxide (λ>420nm) under simulated sunlight and visible light irradiation. Compared with bismuth oxide (λ>420nm) under simulated sunlight and visible light irradiation, sample 400 ha...

Embodiment 3

[0025] Embodiment 3: Optical property characterization of samples

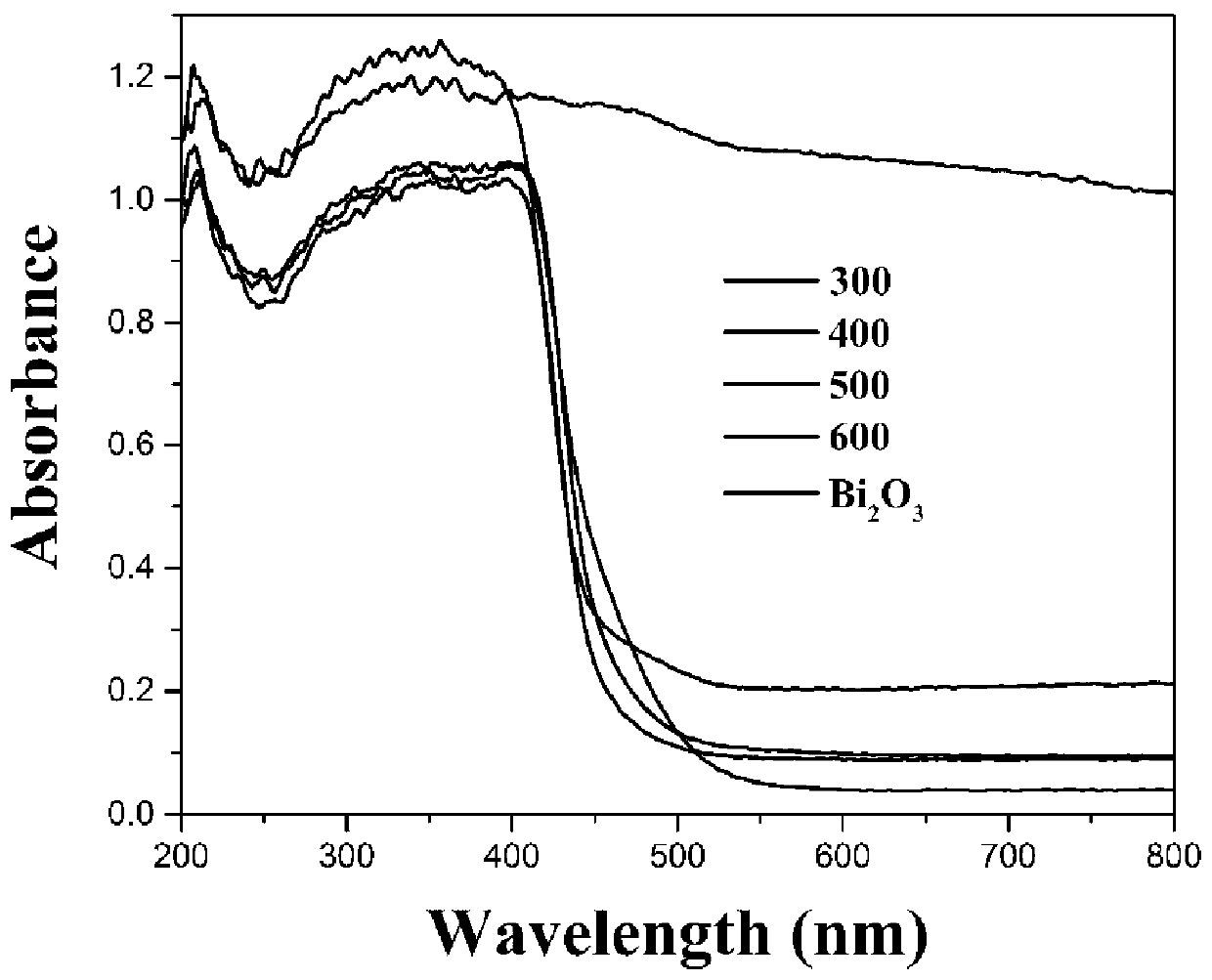

[0026] A Hitachi U-3900 UV-Vis spectrophotometer was used to measure BaSO 4 As a reference, the scanning wavelength range is: 200-800nm, the slit width is 2nm, and the scanning speed is 600nm / min to detect the change of the optical properties of the sample. Changes in the electronic properties lead to changes in the photophysical properties of the material, resulting in changes in the shape and intensity of the spectrum. figure 2 It is the ultraviolet diffuse reflectance spectrum of pure bismuth oxide and bismuth / bismuth oxide / carbon composite photocatalyst. Sample 300 exhibits strong absorption in the UV and visible region due to the large amount of residual organic carbon. Sample 400 has a broad visible band absorption, also due to residual organic carbon. In addition, metal Bi can also enhance the visible light absorption of samples 300 and 400. As the preparation temperature increases, the absorption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com