Positive electrode material for lithium-ion battery and preparation method and application thereof

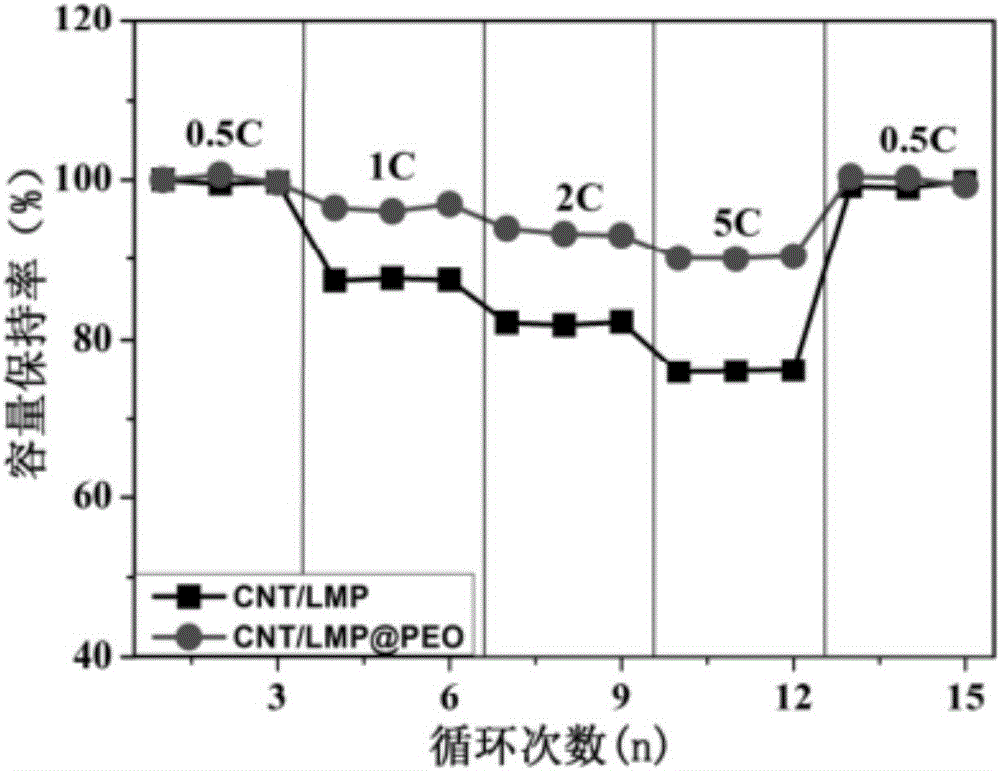

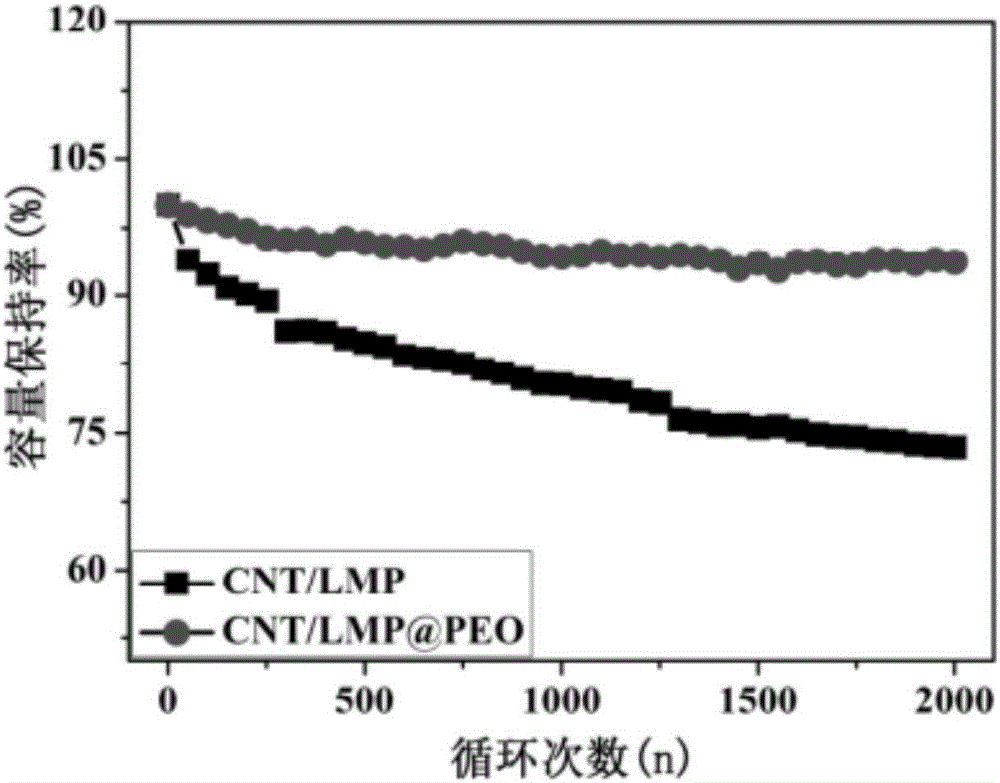

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of material conductivity not being greatly improved, poor carbon conductivity, loose particles, etc., to shorten ion transport Distance, prevention of dissolution in the electrolyte, and the effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Lithium hydroxide, manganese carbonate, ammonium phosphate, tartaric acid according to Li:Mn:PO 4 : H molar ratio 1:1:1:1 mixed, dissolved in a certain ethanol / water mixed solvent to obtain a slurry with a solid content of 65%. A certain amount of single-layer CNT was added to the slurry, and the slurry was ball-milled at a speed of 300r / min for 15h, then dried at 90°C, ground, and passed through a 400-mesh sieve to obtain a mixture of LMP precursor and CNT. The mixture was baked at 650° C. in a tube furnace in a nitrogen atmosphere for 8 hours to obtain an LMP / CNT core-shell material, CNT accounted for 2.5 wt % of the core-shell material, and the particle size of LMP was 100-200 nm.

[0030] PEO with a mass fraction of 0.06% (Mw=1×10 5 ) acetonitrile solution, a certain amount of LMP / CNT core-shell material was added into the solution, then magnetically stirred in an oil bath for 12 hours, and cooled. A high-speed centrifuge is used to separate the solid and liquid t...

Embodiment 2

[0032] Lithium carbonate, manganese acetate, ammonium phosphate, oxalic acid were Li:Mn:PO 4 :H molar ratio 1.5:1:1:1 mixed, dissolved in a certain ethanol solvent to obtain a slurry with a solid content of 70%. A certain amount of 10-layer stacked CNTs was added to the slurry, and the slurry was ball-milled at 400r / min for 10h, then dried at 90°C, ground, and passed through a 400-mesh sieve to obtain a mixture of LMP precursor and CNT. mixture. The mixture was baked at 600° C. in a tube furnace in a nitrogen atmosphere for 8 hours to obtain an LMP / CNT core-shell material, CNT accounted for 2 wt % of the core-shell material, and the particle size of LMP was 100-250 nm.

[0033] PEO with a mass fraction of 0.1% (Mw=1×10 6 ) acetonitrile solution, a certain amount of LMP / CNT core-shell material was added into the solution, then magnetically stirred in an oil bath for 15 h, and cooled. A high-speed centrifuge is used to separate the solid and liquid to remove acetonitrile, dry...

Embodiment 3

[0035] Lithium nitrate, manganese oxalate, ammonium dihydrogen phosphate, malic acid according to Li:Mn:PO 4: H molar ratio 2:1:1:1 mixed, dissolved in a certain acetone / water mixed solvent to obtain a slurry with a solid content of 75%. A certain amount of 20-layer stacked CNTs was added to the slurry, and the slurry was ball-milled for 20 hours at a rotational speed of 200r / min, then dried at 90°C, ground, and passed through a 400-mesh screen to obtain a mixture of LMP precursors and CNTs. mixture. The mixture was baked in a tube furnace under nitrogen atmosphere at 500° C. for 15 hours to obtain an LMP / CNT core-shell material, CNT accounted for 4 wt % of the core-shell material, and the particle size of LMP was 50-150 nm.

[0036] PEO with a mass fraction of 0.14% (Mw=7.5×10 6 ) acetonitrile solution, a certain amount of LMP / CNT core-shell material was added into the solution, then magnetically stirred in an oil bath for 18h, and cooled. A high-speed centrifuge is used t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com