Nutritional health-care radix stellariae beverage

A kind of hemp and nutrition technology, applied in the field of beverage processing, can solve the problem that the high nutritional value has not been widely used, and achieve the effect of improving nutritional value, improving nutrient absorption rate, and promoting metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

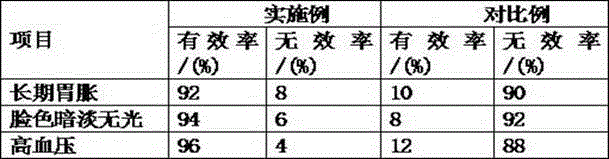

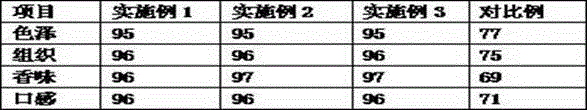

Examples

Embodiment 1

[0019] In the embodiment of the present invention, a nutritious and healthy hawthorn beverage is made of the following raw materials: 180 parts of hawthorn syrup, 13 parts of fresh jasmine, 41 parts of buckwheat, 26 parts of mango pulp, 1.1 parts of glucoamylase, 15 parts of fresh pitaya peel, 8 parts of fresh corn silk, 0.055 parts of momordica charantia, 0.064 parts of sophocarpine, 0.12 parts of grape seed extract, 0.15 parts of fenugreek extract, 1.3 parts of fermenting bacteria, 2200 parts of distilled water;

[0020] The hawthorn slurry is prepared according to the following steps: clean 27 parts by weight of fresh hawthorn stems and leaves, air-dry until there is no moisture on the surface, chop, put 31 parts by weight in water, boil on high fire, and pour into the beater Adjust the speed of the beater to 310r / min and beat for 8 minutes, take it out, add 0.55 parts by weight of cellulase and 0.8 parts by weight of acacia honey, mix and stir evenly, place it in a sealed plac...

Embodiment 2

[0031] In the embodiment of the present invention, a nutritious and health-care hawthorn beverage is made from the following raw materials: 185 parts of hawthorn syrup, 13.5 parts of fresh jasmine, 42 parts of buckwheat, 27 parts of mango pulp, 1.15 parts of glucoamylase, 15.5 parts of fresh dragon fruit peel, 8.5 parts of fresh corn silk, 0.057 parts of momordica charantia, 0.066 parts of sophocarpine, 0.13 parts of grape seed extract, 0.16 parts of fenugreek extract, 1.4 parts of fermenting bacteria, 2250 parts of distilled water;

[0032] The hawthorn pulp is prepared according to the following steps: clean 28 parts by weight of fresh hawthorn stems and leaves, air-dry until there is no moisture on the surface, chop, put 32 parts by weight in water, boil on high fire, and pour into the beater Adjust the speed of the beater to 320r / min for 8.5min, take it out, add 0.57 parts by weight of cellulase and 0.85 parts by weight of acacia honey, mix and stir evenly, and place it in a s...

Embodiment 3

[0037] In the embodiment of the present invention, a nutritious and healthy hawthorn beverage is made of the following raw materials: 190 parts of hawthorn syrup, 14 parts of fresh jasmine, 43 parts of buckwheat, 28 parts of mango pulp, 1.2 parts of glucoamylase, 16 parts of fresh dragon fruit peel, 9 parts of fresh corn silk, 0.059 parts of momordica charantia, 0.068 parts of sophocarpine, 0.14 parts of grape seed extract, 0.17 parts of fenugreek extract, 1.5 parts of fermenting bacteria, 2300 parts of distilled water;

[0038] The hawthorn pulp is prepared according to the following steps: clean 29 parts by weight of fresh hawthorn stems and leaves, air-dry until there is no moisture on the surface, chop, put 33 parts by weight in water, boil on high fire, and pour into the beater Adjust the speed of the beater to 330r / min to beat for 9 minutes, take it out, add 0.59 parts by weight of cellulase and 0.9 parts by weight of acacia honey, mix and stir evenly, place it in a sealed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com