Corn prolamine-shellac-curcumin compound colloidal particles and preparation method thereof

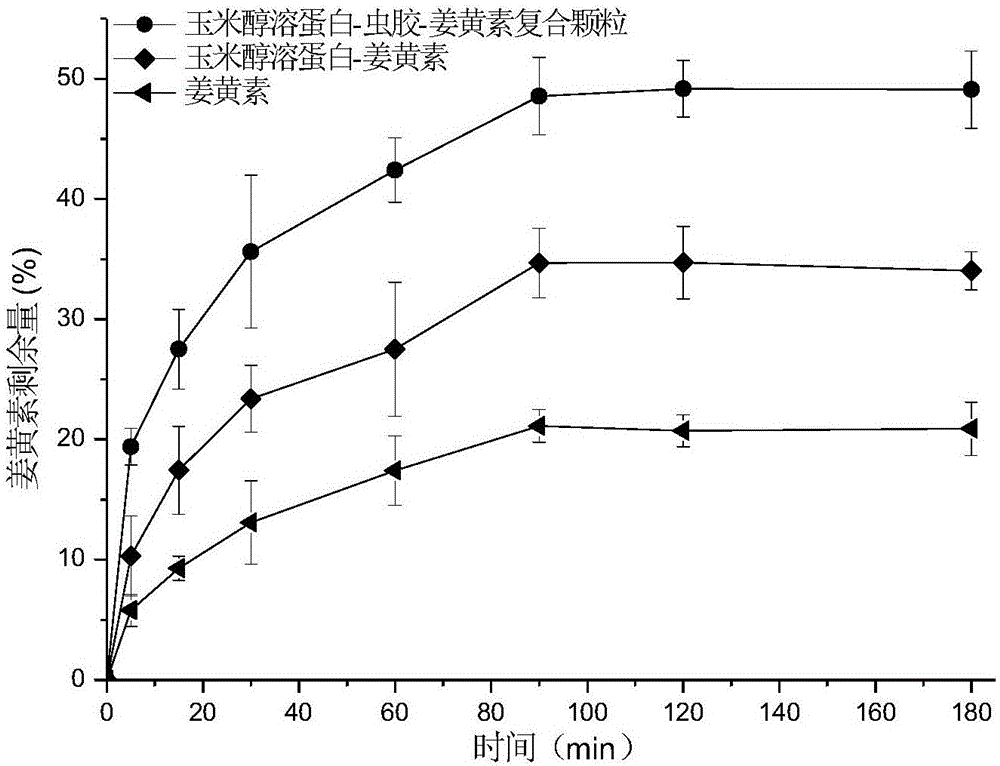

A technology of zein and colloidal particles, which is applied in directions such as capsule delivery, microcapsules, and drug combination, can solve the problems of low chemical stability, poor water solubility of curcumin, and low bioavailability, and achieves a simple preparation method and improved Encapsulation rate and loading capacity, the effect of improving water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

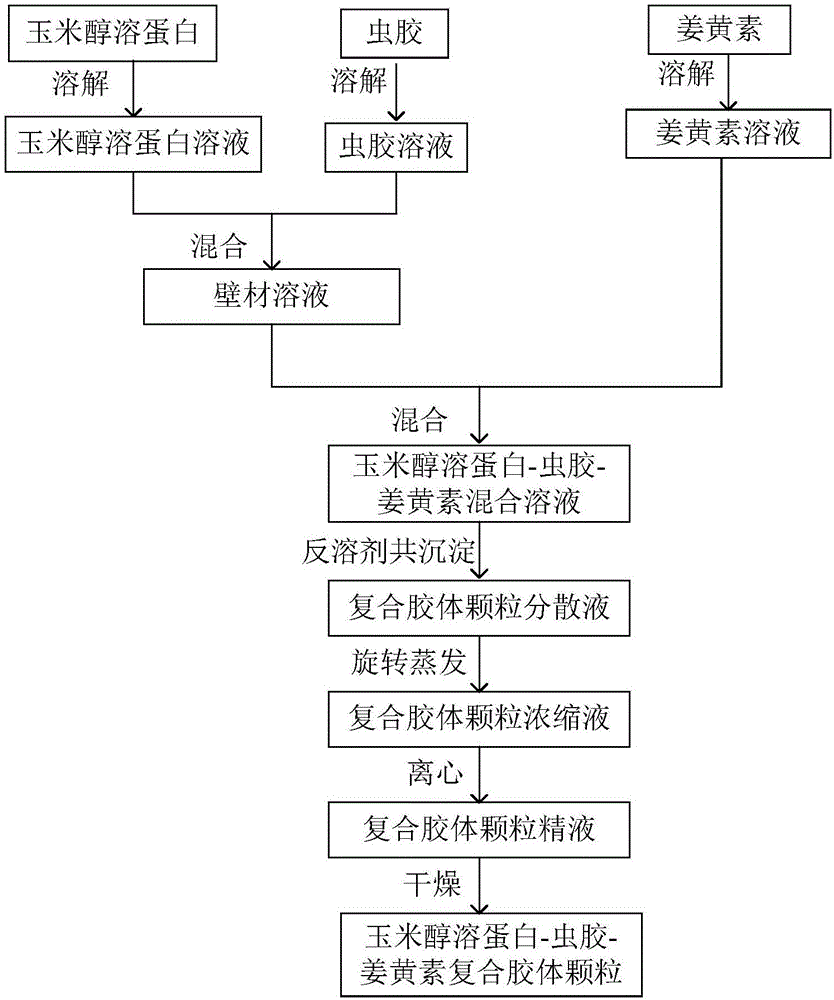

[0027] Dissolve 960mg of zein and 480mg of shellac in 40mL of 0.1M phosphate buffer saline containing 80% ethanol by volume, and stir magnetically (600r / min) at room temperature for 2 hours to fully dissolve them. pH to 8.0; 144mg curcumin was dissolved in 40mL of 0.1M phosphate buffer containing volume fraction 48% ethanol, 40vt% acetone, under room temperature dark magnetic stirring (600r / min) 20min, it was fully dissolved, the turmeric The pH of the solution was adjusted to 8.0.

[0028] Zein solution and shellac solution are mixed in equal volumes, so that the mass ratio of zein to shellac is 2:1, vortexed for 30s, left standing at room temperature for 2h to make it fully mixed to form a wall material solution; Mix the wood material solution and the curcumin solution so that the mass ratio of the wall material and curcumin in the mixed solution is 10:1, vortex for 30s, and stand in the dark for 1 hour at room temperature to form a zein-shellac-curcumin mixed solution .

...

Embodiment 2

[0033] Dissolve 960mg of zein and 480mg of shellac in 40mL of 0.1M phosphate buffer saline containing 80% ethanol by volume, and stir magnetically (600r / min) at room temperature for 2 hours to fully dissolve them. pH to 8.0; 480mg of curcumin was dissolved in 40mL of 0.1M phosphate buffer containing 48% ethanol and 40% acetone by volume fraction, and magnetically stirred (600r / min) in the dark at room temperature for 20min to fully dissolve the turmeric The pH of the solution was adjusted to 8.0.

[0034] Zein solution and shellac solution are mixed in equal volumes, so that the mass ratio of zein to shellac is 2:1, vortexed for 30s, left standing at room temperature for 2h to make it fully mixed to form a wall material solution; Mix the wood material solution and the curcumin solution so that the mass ratio of the wall material and curcumin in the mixed solution is 2:1, vortex for 30s, and stand in the dark for 1 hour at room temperature to form a zein-shellac-curcumin mixed ...

Embodiment 3

[0039] Dissolve 480mg of zein and 480mg of shellac in 40mL of 0.1M phosphate buffer saline containing 80% ethanol by volume fraction, magnetically stir (600r / min) at room temperature for 2h to fully dissolve, and adjust the above solutions respectively pH to 8.0; 480mg of curcumin was dissolved in 40mL of 0.1M phosphate buffer containing 48% ethanol and 40% acetone by volume fraction, and magnetically stirred (600r / min) in the dark at room temperature for 20min to fully dissolve the turmeric The pH of the solution was adjusted to 8.0.

[0040] Zein solution and shellac solution are mixed in equal volumes, so that the mass ratio of zein to shellac is 1:1, vortexed for 30s, left standing at room temperature for 2h to fully mix, and form a wall material solution; Mix the wood material solution and the curcumin solution so that the mass ratio of the wall material and curcumin in the mixed solution is 2:1, vortex for 30s, and stand in the dark for 1 hour at room temperature to form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| embedding rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com