Catalyst for preparing low carbon mixed alcohol through synthesis gas and preparation method thereof

A technology of low-carbon mixed alcohols and catalysts, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problem of low CO conversion rate, structural stability needs further investigation, catalytic reaction performance and product selectivity No advanced problems, achieve the effect of novel structure, prevent agglomeration, and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

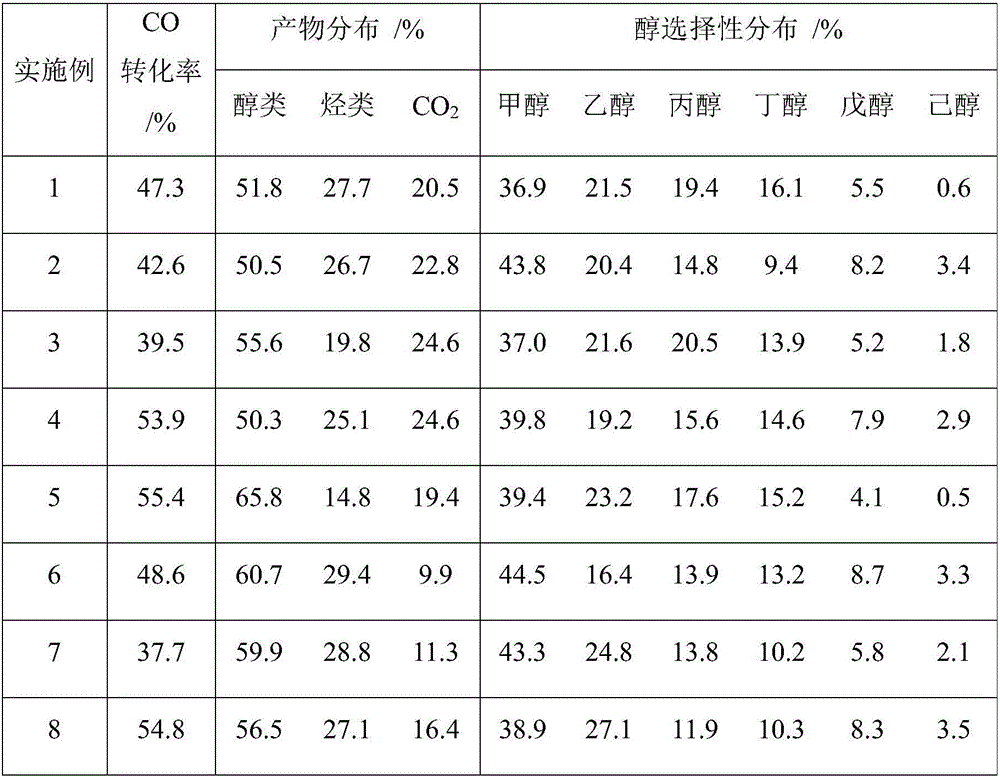

Examples

Embodiment 1

[0027] Weigh 3.53 g of iron acetylacetonate, 14.25 g of cobalt acetylacetonate, 80 mL of dibenzyl ether, 24 mL of oleic acid and 32 mL of oleylamine, then mix them evenly with magnetic stirring, and heat to 150°C for 120 min in a nitrogen atmosphere. After the reacted solution was cooled to room temperature, 60 mL of ethanol was added to wash and centrifuge, repeated 3 times, and then placed in a constant temperature drying oven at 50° C. and dried for 100 min to obtain FeCo-alloy nanoparticles. The FeCo-alloy nanoparticles were re-dispersed into 150 mL of a polyacrylamide absolute ethanol solution with a mass concentration of 8%, and the ultrasound was continued for 120 minutes. Add 2.42g Cu(NO 3 ) 2 ·3H 2 O, continue to stir for 150 minutes, and finally add 2mol / L of NH dropwise 3 ·H 2 O solution, adjust the pH to 10.0. Then, 14 mL of sodium borohydride aqueous solution with a concentration of 5.0 mol / L was quickly added dropwise to obtain a solid suspension with a core-shell...

Embodiment 2

[0032] Weigh 4.04g Fe(NO 3 ) 3 ·9H 2 O, 7.13g cobalt acetylacetonate, 48mL dibenzyl ether, 14.4mL oleic acid, and 19.2mL oleylamine, then mixed with magnetic stirring, and heated to 200°C in a nitrogen atmosphere to react for 60min. After the reacted solution was cooled to room temperature, 80 mL of ethanol was added to wash and centrifuge, repeated twice, and then placed in a constant temperature drying oven at 60° C. for 100 min to obtain FeCo-alloy nanoparticles. The FeCo-alloy nanoparticles were re-dispersed in 120 mL of polyacrylamide anhydrous ethanol solution with a mass concentration of 5%, and the ultrasound was continued for 120 minutes. Add 1.70g CuCl 2 ·2H 2 O, continue to stir for 120min, and finally add 2mol / L of NH dropwise 3 ·H 2 O solution, adjust the pH to 9.0. Then, 14 mL of sodium borohydride aqueous solution with a concentration of 5.0 mol / L was quickly added dropwise to obtain a solid suspension with a core-shell structure. Add 8.0g carrier Al to the susp...

Embodiment 3

[0035] Weigh 4.04g Fe(NO 3 ) 3 ·9H 2 O, 2.91g Co(NO 3 ) 2 ·6H 2 O, 32mL of dibenzyl ether, 9.6mL of oleic acid and 12.8mL of oleylamine, then mixed with magnetic stirring, and heated to 200°C for 120min in a nitrogen atmosphere. After the reacted solution was cooled to room temperature, 80 mL of ethanol was added to wash and centrifuge, repeated twice, and then placed in a constant temperature drying oven at 60° C. and dried for 120 minutes to obtain FeCo-alloy nanoparticles. The FeCo-alloy nanoparticles were re-dispersed in 80 mL of polyacrylamide absolute ethanol solution with a mass concentration of 4%, and the ultrasound was continued for 120 minutes. Add 2.50g CuSO 4 ·5H 2 O, continue to stir for 120min, and finally add 2mol / L of NH dropwise 3 ·H 2 O solution, adjust the pH to 10.0. Then, 20 mL of sodium borohydride aqueous solution with a concentration of 5.0 mol / L was quickly added dropwise to obtain a solid suspension with a core-shell structure. Add 8.0g carrier ZrO t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com