Method for utilizing mixed sludge for preparing porous material to treat hydrogen sulfide contamination gas

A technology of porous materials and mixed sludge, which is applied in the direction of chemical instruments and methods, separation methods, physical/chemical process catalysts, etc., can solve the problems of lack of resource utilization means, high heavy metal content, large volume, etc., and achieve convenient recycling, Realize the effect of emission compliance and efficient treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with specific embodiment the present invention will be described in further detail

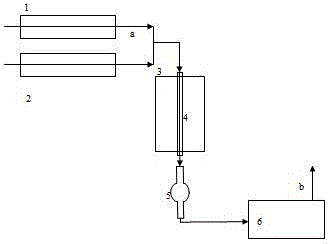

[0021] This embodiment is a method of utilizing mixed sludge to prepare porous materials for processing hydrogen sulfide polluted gas, see figure 1 , figure 1 For its flow chart, the devices used include: 1. Balance gas; 2. Gas to be processed; 3. Quartz reaction tube; 4. Tube furnace; 5. Product recovery device; 6. Tail gas monitoring; a. Gas pipeline inlet; b outlet of treated gas. The raw material used is mixed sludge, which is composed of domestic sludge and electroplating sludge. The weight content of carbon after domestic sludge drying is 55%; the main metal component of electroplating sludge drying is: iron (Fe) The weight content is 10%; the zinc (Zn) weight content is 2%; the calcium (Ca) weight content is 8.2%, and its specific steps are as follows:

[0022] (1). Mix the dried domestic sludge and electroplating sludge evenly at a mass ratio of 1:1, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com