Method for preparing oxygen reduction catalyst by using insect wings as raw material

A technology of catalysts and wings, applied in the field of preparing oxygen reduction catalysts, can solve the problems of unclear understanding of active sites, and achieve the effects of excellent oxygen reduction performance, convenient operation and short reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

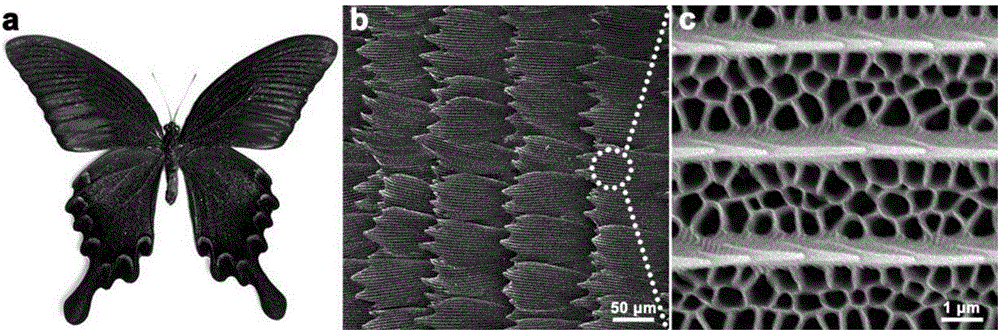

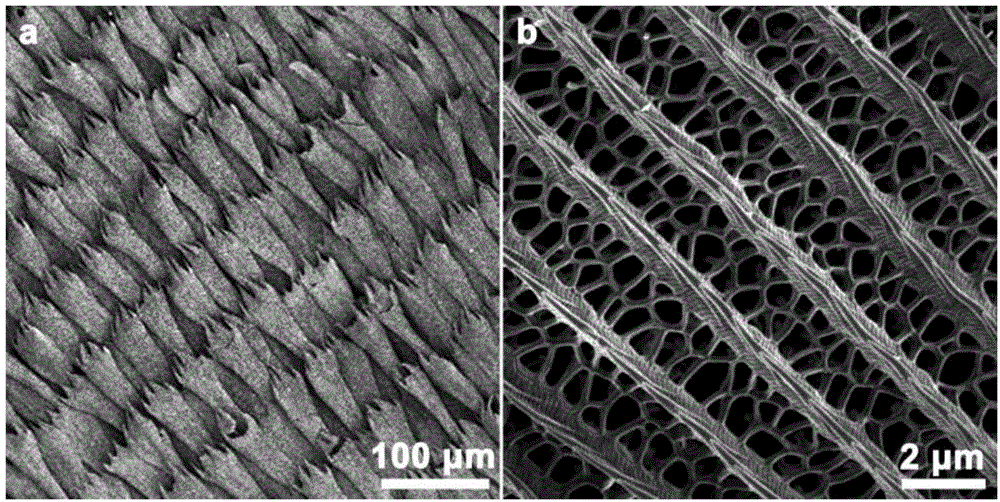

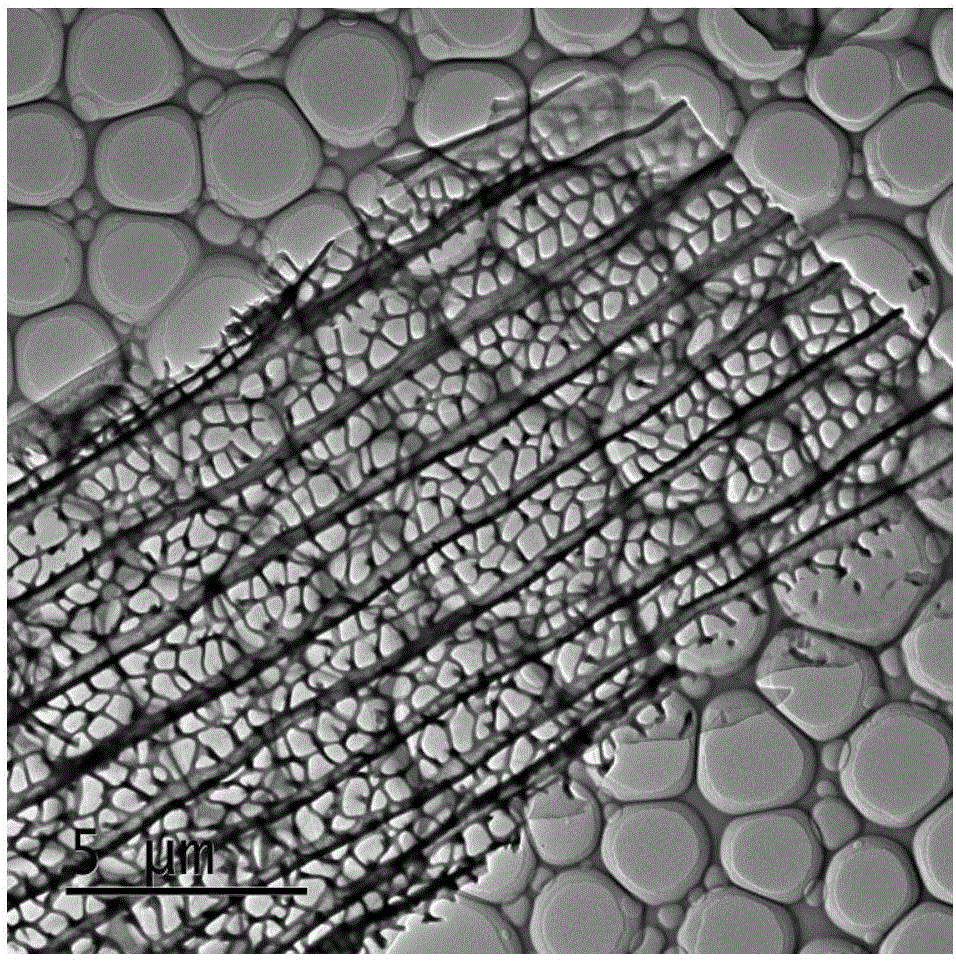

[0044] The insect wings are the wings of the green-banded phoenix butterfly, the carbon black is superconducting carbon black BP2000, the metal salt is ferric chloride, and the nitrogen source is polym-phenylenediamine, hydroxylamine chloride and ammonia gas.

[0045] Specific steps are as follows:

[0046] (1) Take eight pieces of wings (about 0.14g) of the green-banded phoenix butterfly, put them into a hydrothermal kettle equipped with 40mL deionized water, and conduct a hydrothermal reaction in an oven at 100°C for 100 minutes. After cooling to room temperature, take out Wings were dried in an oven at 60°C for 6 hours;

[0047] (2) Weigh 0.81g of ferric chloride, 0.11g of polym-phenylenediamine, 0.34g of hydroxylamine chloride, and 0.12g of carbon black into a 100ml beaker, add 40ml of deionized water, and ultrasonically mix for 0.5 hours to prepare into a homogeneous mixed solution;

[0048] (3) Immerse the dried eight pieces of green-banded phoenix butterfly wings in s...

Embodiment 2

[0064] The insect wings are the wings of the green-banded phoenix butterfly, the carbon black is superconducting carbon black BP2000, the metal salt is ferric nitrate, and the nitrogen source is polym-phenylenediamine, hydroxylamine chloride and ammonia gas.

[0065] The preparation method of the electrocatalytic material is basically the same as that of Example 1, except that the ferric chloride in step 2 is replaced with ferric nitrate. The catalyst material prepared in this example still has excellent oxygen reduction catalytic activity.

Embodiment 3

[0067] The insect wings are the wings of the green-banded phoenix butterfly, the carbon black is superconducting carbon black BP2000, the metal salt is ferric chloride, and the nitrogen source is polym-phenylenediamine, melamine and ammonia.

[0068] The preparation method of the electrocatalytic material is basically the same as that of Example 1, except that the hydroxylamine chloride in step 2 is replaced with melamine. The catalyst material prepared in this example still has excellent oxygen reduction catalytic activity. ,

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com