Ultrasonic transducer with optimized matching layers and manufacturing method thereof

A technology for ultrasonic transducers and manufacturing methods, applied in chemical instruments and methods, lamination auxiliary operations, lamination, etc., can solve the problems of large acoustic impedance mutation, large acoustic impedance gap, and influence of propagation efficiency, and achieve improved performance , Improve the effect of center frequency and frequency response bandwidth improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

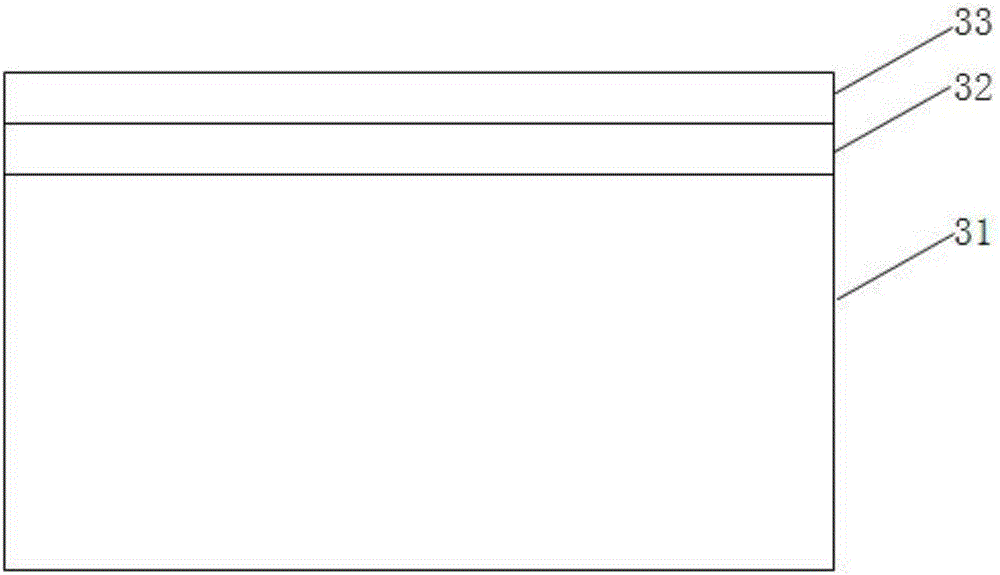

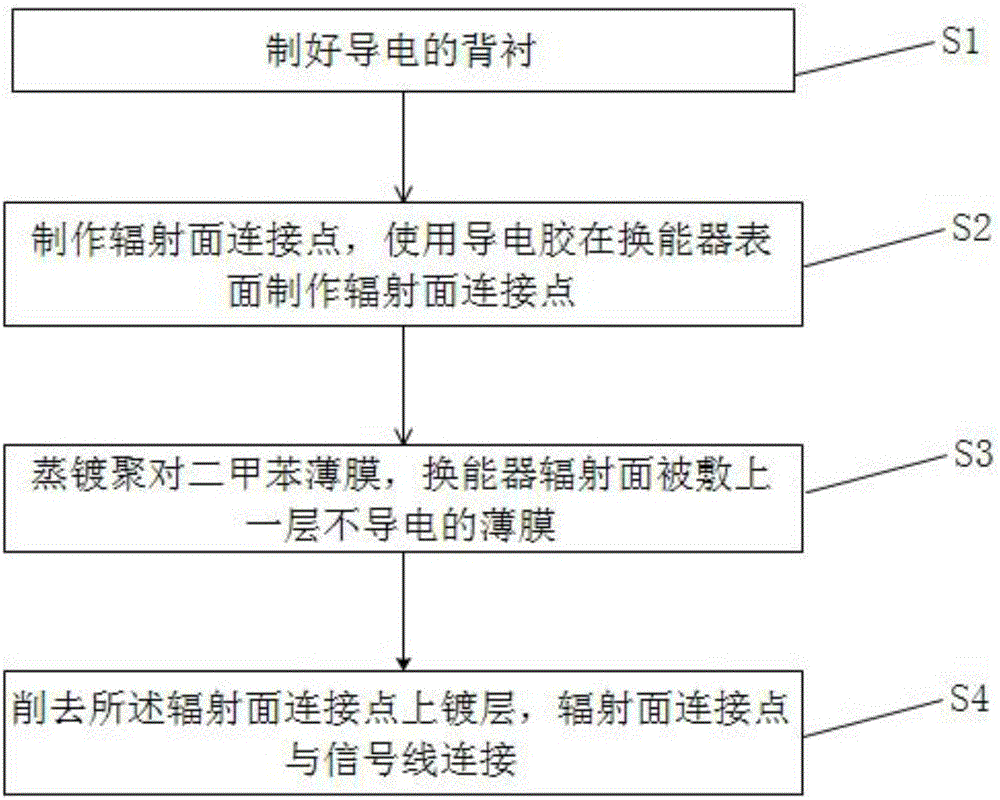

[0045] A kind of ultrasonic transducer with matching layer optimization, comprising: backing layer 31, piezoelectric crystal layer 32 and matching layer 33 connected successively, such as image 3 As shown, make the connecting point of the radiating surface. The conductive backing 31 and the conductive first matching layer 33 are prefabricated. If the piezoelectric crystal 32 is a composite material, the matching layer 33 does not need to be fabricated. The connection points 34 are made on the surface of the transducer using conductive glue.

[0046]Evaporate Parylene, after the first step is completed, perform Parylene evaporation, after the evaporation is completed. The radiating surface of the transducer will be coated with a non-conductive thin film 35, and this layer of thin film 35 is used as the second layer matching of the transducer. If the piezoelectric crystal 32 is a piezoelectric composite material, there is no first matching layer 33, Film 35 is the only layer ...

Embodiment 2

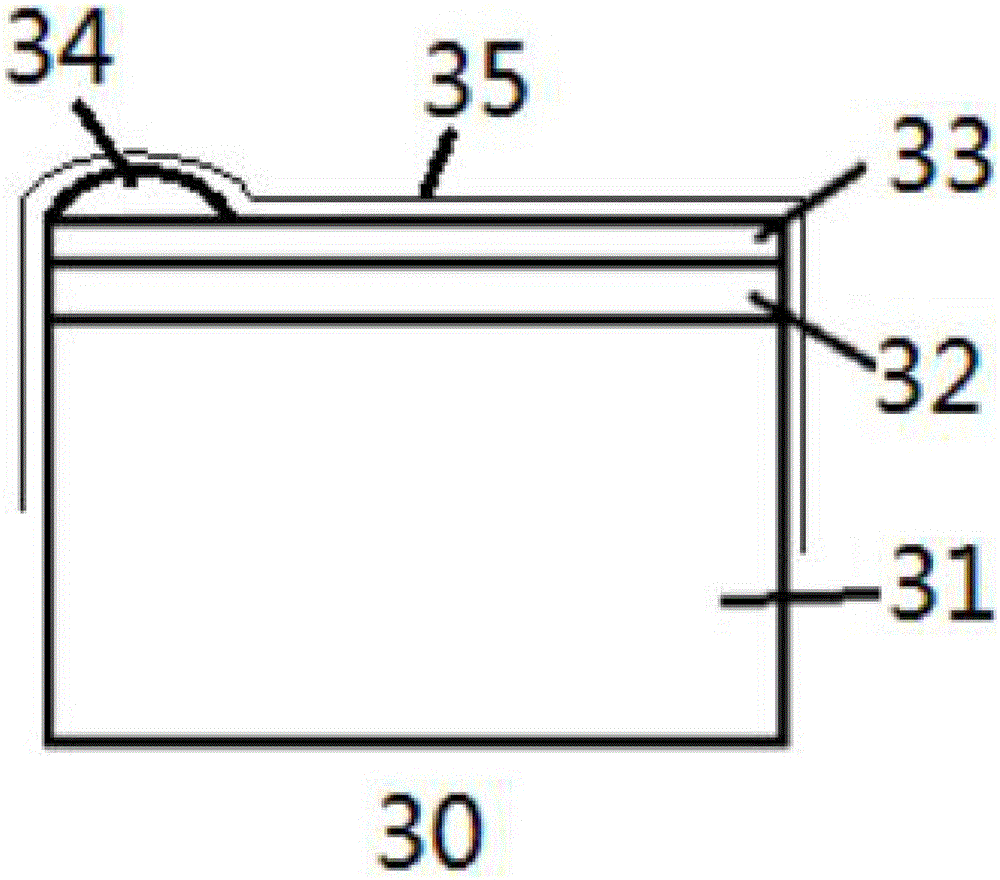

[0049] A kind of ultrasonic transducer with matching layer optimization, comprising: backing layer 31, piezoelectric crystal layer 32 and matching layer 33 connected successively, such as Figure 4 , Figure 5 As shown in the transducer 30, the conductive backing 31 and the conductive first matching layer 33 are prefabricated. If the piezoelectric crystal 32 is a composite material, the matching layer 33 does not need to be fabricated. The radiating surface of the transducer will be coated with a non-conductive thin film 35, and this layer of thin film 35 is used as the second layer matching of the transducer. If the piezoelectric crystal 32 is a piezoelectric composite material, there is no first matching layer 33, Film 35 is the only layer matched. The membrane 35 needs to be designed with an appropriate thickness to allow the transducer 30 to achieve optimal performance.

[0050] connecting cables such as Figure 6 The connecting wires on the Parylene coating 35 are cut ...

Embodiment 3

[0052] A kind of ultrasonic transducer with matching layer optimization, comprising: backing layer 31, piezoelectric crystal layer 32 and matching layer 33 connected successively, such as Figure 6 shown. For the transducer 30, the conductive backing 31 and the conductive first matching layer 33 are prefabricated. If the piezoelectric crystal 32 is a composite material, the matching layer 33 does not need to be fabricated. The radiating surface of the transducer will be coated with a non-conductive thin film 35, and this layer of thin film 35 is used as the second layer matching of the transducer. If the piezoelectric crystal 32 is a piezoelectric composite material, there is no first matching layer 33, Film 35 is the only layer matched. The membrane 35 needs to be designed with an appropriate thickness to allow the transducer 30 to achieve optimal performance.

[0053] Connect the cable, lift a small part of the parylene on the corner of the Parylene coating 35, where the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com