A kind of anti-virus and flame-retardant electromagnetic shielding composite material, preparation method and product

A composite material, electromagnetic shielding technology, applied in shielding, fire-resistant coatings, protective equipment, etc., can solve the problems of poor shielding efficiency, poor weather resistance, complex molding process, etc., and achieve good shielding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the anti-virus and flame-retardant electromagnetic shielding composite material of the present invention adopts a coating finishing and heavy pressing composite process, and the specific steps are:

[0036] Step 1: Test the flame retardant properties of the fabrics of the low-frequency shielding layer 2 and the low-frequency shielding layer 4. If the afterburning of the fabrics of the low-frequency shielding layer 2 and the low-frequency shielding layer 4 is not greater than 10s, proceed directly to the third step. step; if the fabric of the low-frequency shielding layer 2 and / or the low-frequency shielding layer 4 has an afterburn>10s, then proceed to the second step;

[0037] Step 2: Perform single-sided flame-retardant coating finishing on the low-frequency shielding layer 2 and / or low-high-frequency shielding layer 4 whose continuous combustion is greater than 10s. The specific process of coating finishing is:

[0038] a) Prepare polyuretha...

Embodiment 1

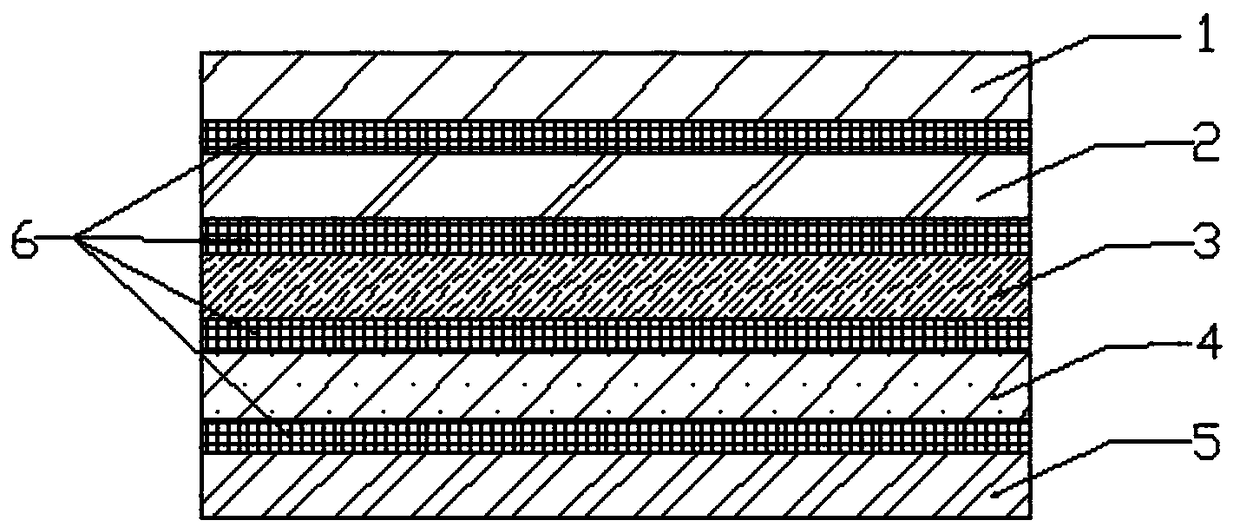

[0057] The anti-virus and flame-retardant electromagnetic shielding composite material of this embodiment includes an outer protective layer 1, a low-frequency shielding layer 2, a barrier layer 3, a low-frequency shielding layer 4, and an inner molding layer 5 from outside to inside, and an adhesive is passed between each layer. connected together in sequence; the square meter weight of the composite material is 420±20g / m 2 , the protection time against mustard gas reaches more than 72 hours, the electromagnetic shielding performance in the 200MHz-40GHz frequency band reaches more than 70dB, and the shielding effectiveness for the low-frequency magnetic field in the 100KHz-20MHz frequency band reaches more than 20dB.

[0058] The outer protective layer 1 of this embodiment is a polyvinylidene fluoride film with a thickness of 0.03 mm. The film has special properties such as good chemical corrosion resistance, high temperature and low temperature resistance, oxidation resistanc...

Embodiment 2

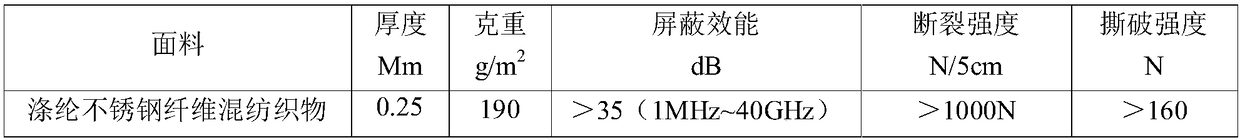

[0079] The composition and preparation method of the composite material in this example are the same as in Example 1, except that the outer protective layer of this example is a polyvinylidene chloride copolymer film with a thickness of 0.05 mm; the low-frequency shielding layer is a polyester stainless steel fiber blended fabric, square meters Gram weight is 120g / m 2 ;The barrier layer is polyester (PET) film with a thickness of 0.015mm, good mechanical strength, high hardness, excellent barrier performance, low temperature resistance, environmental protection and non-toxic; low-frequency shielding layer is nylon copper-nickel coating Fabric, the square meter weight is 50g / m 2 ; The inner molding layer is a flame-retardant polyethylene copolymer film with a thickness of 0.05mm; the materials of each layer are bonded and compounded by polyurethane adhesive in point form. The square meter weight of the composite material is 335±20g / m 2 , the overall thickness is 0.4mm.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com